exist2022Year11moon16Earlier on Wednesday, Artemis (Artemis) After Rocket 1’s test flight with three dummies, NASA’s Orion spacecraft deployed four planes spanning approximately63feet of solar panel on the way to the moon. After years of delays and billions in cost overruns, the rocket launched from the Kennedy Space Center in Florida.Artemis Iis the first in a series of increasingly complex missions that will enable human exploration of the Moon and Mars.

Lockheed–Martin’s Space Launch System (SLS) the moon landing rocket reached in a few seconds160kilometer/hours flying the Orion capsule, proving it is the most powerful rocket in the world, capable of carrying more payloads into deep space than any other vehicle. With its unprecedented power and capabilities, NASA’s Artemis 1 mission plans to travel beyond the Moon by approximately4Ten thousand miles, in25Return to Earth in a few days.

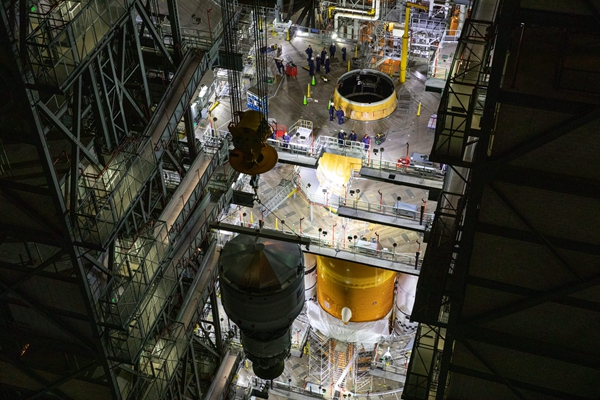

△2020Protective shields were placed on both wings of the solar panels after they were installed on the Orion spacecraft at NASA’s Kennedy Space Center in Florida for Artemis 1. Image source:NASA/Frank Michaux

The project to return to the Moon after the Apollo program

When four of the rocket’s origins derived from those of the Space ShuttleRS-25Basic Stage Engine (made byAerojet Rocketdynemanufacturing and business upgrade) Ignite, a valuable helpSLSrocket39BWhen the launch pad took off, for the first timeArtemisThe mission begins. These fourRS-25The engines are designed to withstand some of the most extreme temperatures as they move large amounts of propellant to create enough energy to lift a rocket out of Earth’s gravity, and these four engines have many3Dprinted parts, while maintaining performance, reliability and safety, the collaboration closely reduces overall engine production costs.35%。

Aerojet provided a total of39propulsion elements (38a liquid engine and a solid rocket engine), and14A high pressure tank. For most propulsion devices,AerojetThe company uses metal additive manufacturing technology, which has been with the company for more than two decades. Additionally, time and resources are invested in3DIn printing processes such as laser powder bed fusion (LPBF) to successfully design and integrate propulsion systems into a variety of spacecraft.

△From NASA’s Stennis Space CenterA-1carried out on the test benchRS-25Engine hot fire test. Photo byAerojet Rocketdyneprovided by the company.

Artemisand more3DPrint parts

Additionally, two solid rocket boosters provided more than75%thrust of the plane. AndRS-25Engine identical to that of Northrop–The booster built by Grumman is modified from a component inherited from the space shuttle program and benefits from additive manufacturing, which makes it compatible withSLSCompatible with an orbital transporter.

2020In , Northrop shipped ten rocket engine segments from Promontory, Utah, to the Kennedy Space Center. The engine segments were assembled into two solid rocket boosters launched into space yesterday. Developed by Northrop Corporation’s Northern Utah team to720Thousands of pounds of powerful thrustSLSThe spacecraft’s two solid rocket boosters rely on3DPrinting and computer modeling, this technology is becoming more and more common in businesses.

△The solid rocket booster isSLSThe first stack of rocket components will help support the remaining rocket components and the Orion spacecraft. Image source:NASA/KimShiflett

Based on tradition, start the journey again

Separated centrally and approx.40After a few minutes of being on land,SLSThe temporary cryogenic propulsion stage (ICPS),Depend onAerojetRocketdyneManufactured by the companyRL10B-2The engine provides power, producing24,750pounds of thrust, took over, executing the first of two planned burns to place Orion in a stable orbit above Earth.

50Over the years, Air JetRL10It has always been the most important rocket final stage engine in the United States. It is known as the workhorse of the launch industry.1959first tested in 2016 and helping send spacecraft to every planet in the solar system, including Voyager1and New Horizons, the fastest spacecraft to leave Earth’s orbit.RL10B-2from the originalRL10and adopted3Dprinting technology to reduce production costs while benefiting from the performance and design capabilities of the technology.

△InNASAKennedy Space Center,NASAThe team willNASAofSLSrocketICPSwith a hugeSLSLauncher stage adapter above the main stage (LVSA) for integration. Image source:NASA/Kim Shiflett

After reaching its initial orbit, Orion deployed its solar panels and engineers began inspecting the spacecraft’s systems. Then, about an hour and a half into the flight, the rocket’s final stage engine successfully lifted off about18minutes, giving Orion the huge boost it needs to get it out of Earth’s orbit and toward the Moon.

Over the next few hours, a series of10A small scientific investigation and technological demonstration continuedCubeSatlit, unfolding from a ring connecting the upper stage to the spacecraft. eachCubeSatEach has its mission and has the potential to fill gaps in space knowledge or demonstrate technologies that could benefit the design of future exploration missions to the Moon and elsewhere.

The Orion Service Module will also be deployed approximately after launch8hour to carry out the first in a series of burns to maintain its path to the Moon. The cabin should be11moon21The Sun flew past the Moon, approaching relatively close to the lunar surface before heading into its distant retrograde orbit, a very stable orbit thousands of kilometers beyond the Moon.

△2022Year11moon16On the same day, people witnessed the launch of NASA’s Space Launch System rocket carrying the Orion spacecraft for the Artemis 1 flight test. Image source:NASA/Bill Ingalls

Jim, NASA deputy associate administrator for the Exploration Systems Development Mission Directorate–Fried said:“This successful launch means NASA and its partners are on track to explore space further than ever before for the benefit of humanity.“

passArtemismission, NASA will land the first woman and first person of color on the lunar surface, paving the way for the Moon’s long-term presence and becoming a stepping stone for astronauts heading to Mars. First of allArtemisThe launch marks the start of one of the most closely watched space programs of the decade. If all goes well, the next rocket launch mission, calledArtemis IIwill not be before2024It will take four astronauts to circumnavigate the Moon.ArtemisNo. 3 will then carry out a manned landing mission.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.