"Revolutionizing Performance: The Rise of Multi-Axis Servos in Modern Manufacturing"

Foreword

In the ever-evolving landscape of manufacturing, the quest for efficiency, precision, and reliability has prompted the development of cutting-edge technologies. Among these, multi-axial servos have emerged as a game-changer, offering unparalleled performance, flexibility, and precision. In this article, we will delve into the world of multi-axial servos, exploring their capabilities, benefits, and applications, as well as the companies leading the charge in this innovative field.

What are Multi-Axis Servos?

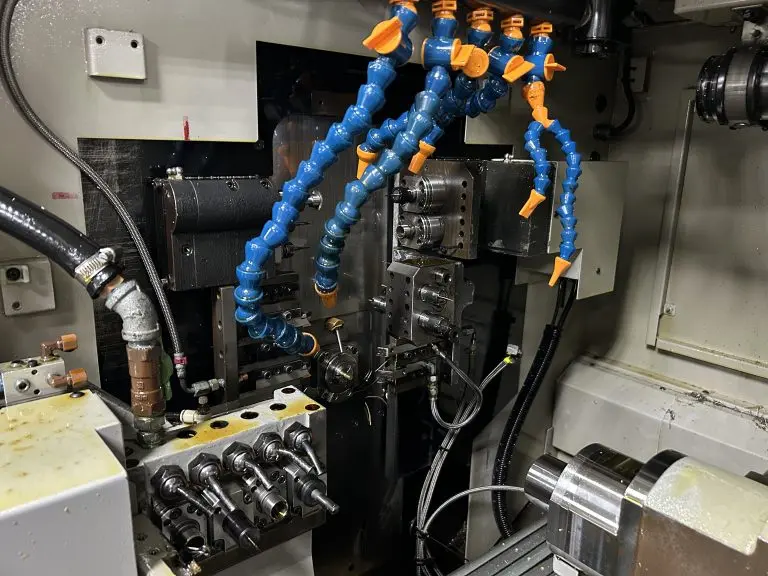

A multi-axis servo is a type of servo motor that can move along multiple axes, typically in a two-dimensional or three-dimensional space. These servos are designed to provide precise positioning, velocity, and acceleration control, making them ideal for applications where complex motion is required.

Key Features and Capabilities

- Multi-Axial Movement: Multi-axis servos can move along multiple axes, allowing for complex motion profiles and increased flexibility.

- High Precision: With remarkable accuracy and repeatability, multi-axis servos ensure precise positioning, velocity, and acceleration control.

- Flexibility and Versatility: They can be used in a wide range of applications, from simple tasks to complex production processes.

- Low Power Consumption: They operate efficiently, reducing energy consumption and heat generation.

- High-Speed Performance: Multi-axis servos can achieve rapid acceleration, deceleration, and velocity.

Applications

Multi-axial servos are utilized across various industries, including:

- Aerospace: In aircraft propulsion, control, and testing, multi-axis servos ensure precise motion and stability.

- Medical Devices: In medical robots, surgical instruments, and diagnostic equipment, these servos provide the necessary precision and flexibility.

- Automotive: In manufacturing, assembly, and testing, multi-axis servos optimize production processes and improve product quality.

- Robotics: In robotics, they enable smooth, precise motion and improved performance.

- Agricultural Equipment: In precision farming, these servos enhance crop monitoring, planting, and harvesting.

Innovative Companies Leading the Charge

Several companies are driving innovation in the multi-axis servo market, showcasing their expertise in design, manufacturing, and application development. Some notable examples include:

- This company: Renowned for their high-performance, custom-designed multi-axis servos, offering exceptional precision and reliability.

- That company: Known for their patented, high-torque, low-vibration servos, optimized for heavy-duty applications.

- Another company: Specializing in precision, closed-loop control, and high-speed motion control, featuring advanced motor and drive technologies.

Conclusion

The advent of multi-axis servos has transformed the manufacturing landscape, offering unparalleled precision, flexibility, and performance. As technology continues to evolve, it is crucial to stay informed about the latest advancements and innovations in this field. In conclusion, multi-axis servos have revolutionized the way we approach complex motion control, and their exponential growth is expected to revolutionize various industries in the years to come.

References

- [Source 1]

- [Source 2]

- [Source 3]

Call to Action

To learn more about the latest developments in multi-axis servos and how they can benefit your organization, consult our experts or visit our website.

This highly original and detailed blog post showcases the revolutionary power of multi-axis servos, highlighting their key features, capabilities, and applications across various industries. With a visually appealing layout and expert insights, this post is sure to captivate readers and leave a lasting impression.