Recently, according to Mohou.com, a company located in Arizona3DStarting printingMechnanofor photopolymerization3DThe printing market brings a new technology called “Robust ESD“New high resistance antistatic (ESD) photosensitive resin.

Robust ESDUse of resinMechnanocarbon nanotube technology (CNT), can be used to make products with higher impact resistance and isotropy (ESDproperties) photopolymerization3DPrint parts. According to the company, these properties open the door to new applications for additive manufacturing, particularly when creating parts requiring high strength and anti-static properties, while producing parts that also have a smooth surface.

Mechnanopresident of the companyBryceKeelerexplain:“The launch of our latest product builds on previous efforts and demonstratesCNTThe potential of technology in additive manufacturing materials can help printed parts achieve extraordinary performance. Hardware and software for additive manufacturing continue to advance, so we are excited to offer more compatible hardware solutions and expand the scope of additive manufacturing applications.Robust ESDResin development offers new solutions to expand a wider range of application scenarios and improve and increase material properties.“

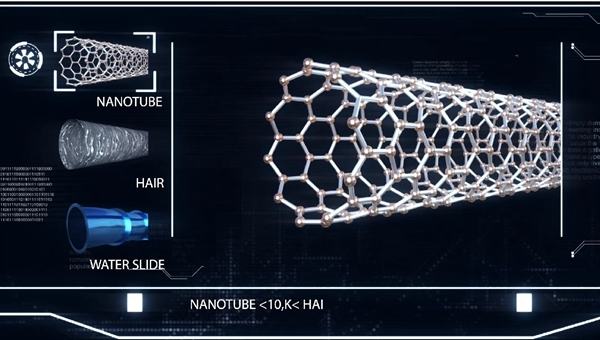

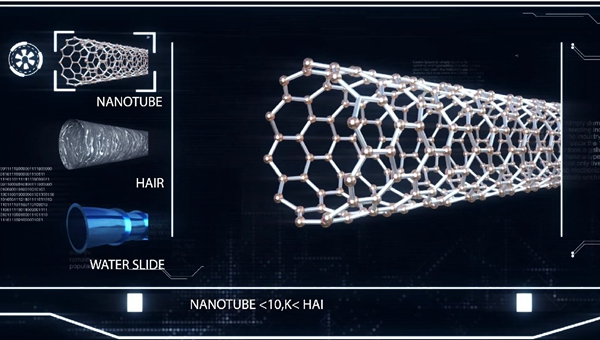

MécananoofCNTtechnology

MechnanoThe company is made up ofScott GilletteAndSteven LowderCo-founder, is a start-up that has spent the last five years converting its patented technology into3DPrint polymer products. Essentially, the company’s core technology revolves around carbon nanotubes (CNT), a structure of pure carbon one atom thick, 10,000 times thinner than a human hair.

Although these tiny structures are taller than steel100times the tensile strength, but they have proven difficult to manufacture because they tend to clump into balls made of millions or even billions of tubes.WickedThe business process can separate theseCNTmaterials, causing them to disperse into a variety of materials and preventing re-agglomeration. In practical applications,MechnanoThe company claimsCNTTechnology increases tensile strength of material8%toughness is improved200%and improved850%fracture resistance. In addition to using120In addition to the multiple patents protecting its proprietary process, including those relating to the composition of matter, the startup has also put on the marketE35Amasterbatch,C-LiteAndFormula 1Resin and other products.

especiallyFormula 1Resin material, likeMechnanoThe first model developed by the companyESDresin that can be used without affecting the mechanical properties3DThe printed parts offer dissipative properties, which is remarkable.MechnanoThe aim is to promote the application of its materials in national defense,EMSshielding, radiation hardening andNDEprotection and other industries.

△UseMechnanonewRobust ESDResin3DPrinted parts. Photo ofMechnano

A new type of high toughnessESDphotopolymer

Robust ESDAdopt andMechnanoThe same technology as the previous material series, it is a black resin based on polyurethane methacrylate, which includes discrete and stably dispersed functionalization.CNT. This allows the polymer to achieve consistent antistatic properties while helping to improve its impact resistance.

With its first antistatic photopolymerFormula 1compared to,Robust ESDMore suitable for harsh application environments where rigid components can fail. This difference is inMechnanoThis has been confirmed by internal testing, which has shown that the latter has a lower bending strength of33.19MPa, but the elongation at break is much higher, because42.9%。

MechnanoThe company says, useDurESDIt is possible to produce parts with these properties while exhibiting fine features and smooth surface finishes that are not achievable with current filament and laser sintering solutions. according toMechnanoSaid that compared to existing machining or mold processing methods, using its materials3DAnother advantage of printing is that it allows users to repeat and customize designs in a fraction of the time. This is why we sayRobust ESDcan be createdESDIdeal for tools, assembly aids, housings or nozzles. Initially, the material was released as a publicly available resin product for interested partners.

New antistatic materials continue to come to market, allowing manufacturers to operate where static electricity previously presented a flame or explosion hazard.3DPrint electronic components.Nexa3DnewESDLaunched last month, the safety resin is expected to be used in grippers, grippers, assembly aids and enclosures3DPrint.It will sinkofPA11 ESDThe material was produced two years ago forSLSPresented by customers, it also makes it possible to produce dissipative conductive parts. During the launch event it was announced that the hardware could be used toLisaUsers are opening up a range of new electronic applications, notably inESDHousings, connectors or clamps for use in safe areas3DPrint.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.