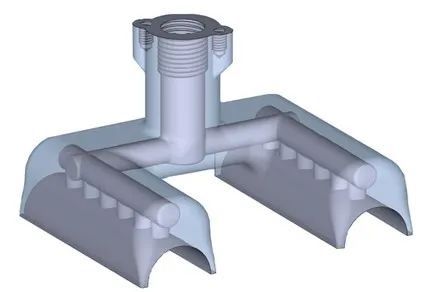

The production tools are additive manufacturing (AM) One of the apps that really shines. This redesigned stand is a great example. This gripper is used in mass production systems to lift lightweight cylindrical objects.Come to fruitionMaris worked closely with the customer to redesign the gripper, resulting in several significant improvements. One of them is that the manufacturing cost of each clamp is reduced by half.

▲Customers use3DPrinted design

The customer’s pliers were initially manufactured using traditional production tooling. Several straight holes were drilled in different directions to intersect to form the necessary internal passages, and the openings were sealed with blank plugs. In order to avoid a further increase in component costs, the customer did not carry out any further milling work that would have reduced the clamping volume.

The customer had prior experience in additive manufacturing of plastic parts and knewAMAdvantages in terms of cost and efficiency, particularly in production tools. However, before doing a redesign, they should first think about whether the holder is necessary for the application.3DPrint. Compare their clamp requirements with3DA comparison of the possibilities provided by printing leads to a clear result:3DPrinting can reduce the cost of manufacturing the clamp, reduce its weight and facilitate faster movement, resulting in shorter clamping cycles. The clamp can also have better vacuum distribution and reduce errors and failures.AMFree design can achieve all of the above.

The material chosen by the customer is aluminum. On the one hand, metal is lighter and more resistant to wear than plastic. On the other hand, it creates a smooth, easy-to-clean surface, making it easier to keep fixtures clean during production. Additionally, aluminum is economically very suitable for use in small and medium-sized, high-value, low-volume components.

at the customer himselfAMOnce development and design is complete, they hope to succeedCome to fruitionHusbands produced. Our design and engineering team quickly realized that the design could be further improved. Although the customer’s design has significantly reduced the weight of the part, the production cost of this design is higher than the original traditional production method and the internal channels are not aerodynamically optimized.

▲ Siemens NX achieves formmodule

After the customer’s approval, our engineers began to further optimize the design. Allows free-form modeling usingSiemens NX achieves formThe module is redesigned. The experts also succeededMagicsThe geometry of the printing process is optimized by the software’s preview function, which displays all necessary support areas of the component in the selected orientation, ensuring that no support structure is required inside the component. This mounting arrangement allowed the design team to further reduce the number of required support structures and optimize the quality of the contact surfaces in the clamping area. The new version of the design ensures uniform vacuum distribution at the clamping points, allowing more efficient clamping of the cylinders.

▲Photo01:Materializing magicPreview function displays minimum required media (LEFT),part (RIGHT) Shows unsupported channels.

Afterwards,Come to fruitionThe engineering team smoothed the material thickness transition areas to reduce stress lines in the component. This is important because tension wires affect not only the appearance of the component, but also the mechanical properties of the final part.

In this way, the volume and overall weight of the assembly are minimized. Different from metal cutting process,3DMost of the unused materials in metal printing can be recycled and directly reused, thereby directly reducing material costs. This ensures that only the materials actually needed for components and supporting structures incur costs. Small supports and minimized contact surfaces with components in non-critical areas also facilitate post-print handling. This allows customers to remove the support structure easily and saving time. In the end, just cut the assembly threads.

original with customer3DCompared to printed models, this version of the design has great advantages in terms of time and cost control: the number of components in each construction has increased from28increased to46individual. The new component geometry allows for a more efficient layout on the build platform, which also reduces the unit price.

▲Photo02: View of the clamp suction area

▲Photo03:against3DClamps optimized for printing

original tool, first3DA comparison of volume and manufacturing costs between the printed model and the final design shows the enormous progress made in design optimization: although the initial volume of the customer’s design model was reduced compared to the volume of the original tool.79%but afterCome to fruitionThe optimized clamp now only has the original component volume6%。Come to fruitionThe cost per part of the version has also been reduced to150 Euros, the production cost of customer’s first design will be higher6%。

Overall, the gripper example shows how additive manufacturing and optimized additive design can be used to achieve cheaper, lighter and functionally optimized production tools. This example also demonstrates the decisive impact that the quality of the redesigned tool can have on the profitability of the project. Given these huge improvements, the client decided to optimize the3DPrint templates to make their pliers.

source: Come to fruition Husbands

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.