2022Year11moon15day,MakrforgedAnnouncing the release of simulation testing tools Simulationallowing users to simulate part strength before generating optimal print parameters to speed up lamination3DThe printing process of printing. althoughWrought(NYSE:MKFG ) with its continuous carbon fiber (CCF) and metal extrusion 3D It is famous for its printers, but it also develops excellent software.Makrforgedoriginally in2019Launch of the print management toolEigerfollowed by2021Launched inDigital ForgingSoftware portfolio.

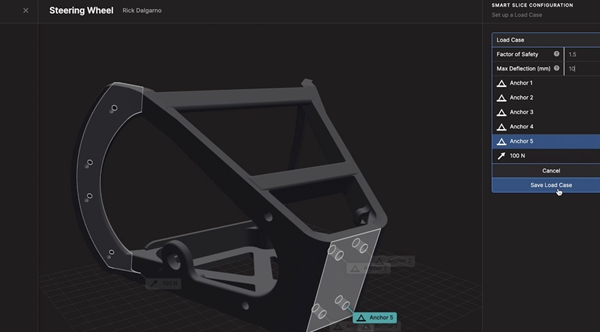

SimulationEasy to use for different users to check the model before printing it. Users can enter safety factors and loads to create the necessary support structures, materials, and other parameters for different parts of the part. racing companyLarsen Motorsports to use CCF (continuous carbon fiber)3D Printed to produce composite steering wheels designed for racing drivers Josette Roach Customized, can be used as replacement for aluminum parts.Larsen Motorsports Director of Operations Brian Tocci “We can now use simulation to test it, iterate, and keep iterating until we get a design that we’re happy with. Instead of printing ten different parts, we can just do everything in simulation,” he told about the device.

△Racing driver Josette Roach By taking your personalized steering wheel, using analog andSimulationTechnical progress 3D Print.

Photo by Wrought provide.

Wrought CEO Shai Terem explain:”SimulationEnables our customers to predict products with continuous fiber reinforcement in advance using validated and optimized models 3D Print the status of advanced composite parts for deeper adoption in their manufacturing operations The digital forge. pictureSimulationSoftware innovations like this are at the heart of our goal: to bring industrial parts production to the point of demand. “

SimulationWhat are the advantages?

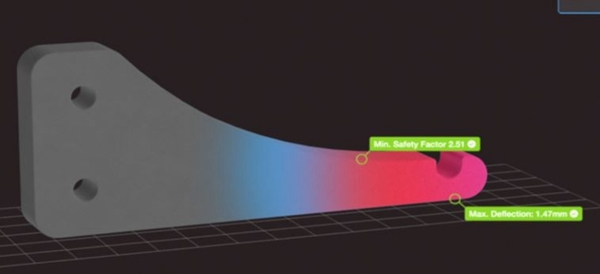

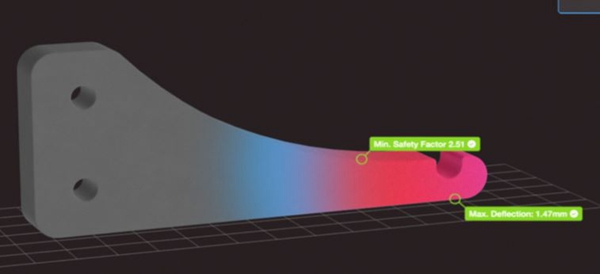

WroughtPromises to provide a fast, automated way to verify part performance, making it quick and easy to print precisely optimized parts for the most demanding end-use applications. Simulation in the slicer means no more lengthy designs–Print–Interrupting the testing cycle is often costly and time-consuming.

●SimulationAllows users to make sure before printing3DPrinted parts will have the strength required for industrial applications. Powerful simulation technology optimized for additive manufacturing allows any user to simulate test parts to meet performance requirements without having to guess print parameters.

●SimulationBy reducing the design–Print–Test iteration cycles and rework times, enabling users to deliver reliable parts faster. Unlike traditional simulation tools that require specialized knowledge and tedious analysis,Simulation integrated into Eiger (WroughtHAS2019software introduced in 2017) and streamlined for additive manufacturing so users can test parts within their familiar cutting and printing workflow.

●SimulationReduced by automatically optimizing the amount of material and continuous fiber reinforcement required 3D Cost of printing parts. Avoid overmanufacturing parts and wasting materials with settings optimized to meet user needs for strength, cost and print speed. Use Mock Tests Instead of Traditional Tests 5 arrive 25 Trial-and-error printing experiments can save hundreds or even thousands of dollars per part. Ultimately, this could expand the use of fiber-reinforced composite parts, allowing more metal tools and end-use parts to be replaced faster, cheaper and easier.

Develop digital manufacturing

Wrought is looking to further expand its software into manufacturing floors with an expanded solutions platform. This allows businesses to be more profitable because long-term software usage fees generate ongoing revenue. As one of the primary software interfaces used by engineers every day,WroughtCan play an important role in workflow. at the same time,Wroughtof 3D CCF The printing process is also unique and users must learn the technology to create the most qualified product possible.CCFof parts.

Software is a critical factor in the production process. if Wrought If the software cannot help users design their printing process well, using the printer will become more and more troublesome. Some processes, notably metal powder bed fusion, often leave the technology in the hands of just a few people in a company. A single person can produce millions of crowns and bridges in a semi-automated process with very few designers involved. The same is true for many mass manufacturing applications. But for a tool to be used to solve problems on and off the shop floor, it must be accessible to a large number of people. If an employee must use Markforged 3D printer, but doesn’t know how to design it, so he’ll never actually use it.

Continuous carbon fibers are a technology with a wide range of applications. They can be used to reduce weight, create new parts that would otherwise be impossible, or completely redesign complex components. However, the software must be extremely simple and quick to learn so that everyone on the shop floor adopts it. in this case,Wrought Investing in software is not only an income-generating opportunity, but also a necessary way to remove barriers to technological flourishing.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.