ceramic3DGlobal market and innovation leader in the printing industry Lithoz GmbH Already2022The year is considered the most successful year and the volume of orders is2021Twice a year.2022It’s almost over,LithosSales results show that20222020 is an important year for expanding the production scale of ceramic additive manufacturing technology to industrial levels. passLCMMass production technology has attracted various fields and more and more customers from industries such as aerospace, dental, medical and electronics are taking advantage of this powerful process.

aboutLithos

AustriaLithosThe company is the world leader in ceramics3DSuppliers of printing equipment and materials, powered byLithosceramic3DProducts produced by the printer have a surface roughness of up to0.4-0.6 mmwith a density as high as99.4%Above, the physical and chemical properties of the product are equivalent to those of traditional processing products. Currently, alumina, zirconia, tricalcium phosphate, silicon nitride, silicon materials, cermets, etc. are used. can be printed.20remaining materials. Since2016For years,LithosI also hadISO 9001-2015Certificate.

LCMtechnology

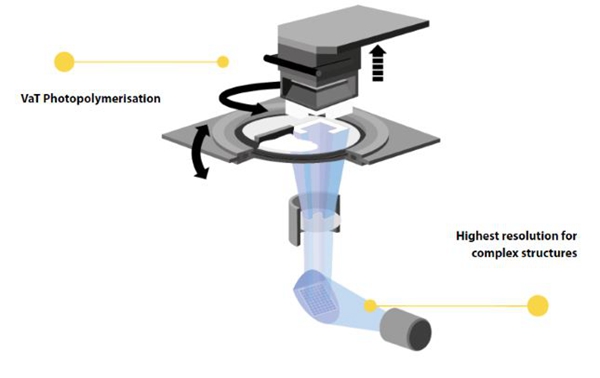

LCMThe technology is based on the selective curing of a photosensitive resin containing uniformly dispersed ceramic particles. It uses photopolymers as binders between ceramic particles, enabling the precise production of denser ceramic greenbodies. At its core is a specially designed imaging system capable of passing the latestDIRECTEDThe technology transforms each layer of information and projects it onto a photoresist. This imaging technology, combined with special optical projection components, can create small structures with very fine detail.3DPrint ceramic parts with high precision, fine details, high density and strength. The main material is a mixed liquid of ceramic and photosensitive resin.

△LCMtechnology

Lithos Co-founder and Chief Technology Officer Jean Benoit The Dr. is extremely proud of what his team accomplished this year. He highlighted the enormous potential of combining ceramics as a powerful material with the geometric freedom of additive manufacturing.

As new and old industry partners increasingly invest in additive manufacturing technology,Lithos Machine sales have almost doubled this year, bringing the LCM established as ceramic 3D Our mission: to become the standard in the printing industry. In addition to reaching a major milestone in machine sales, the company now has several final manufacturing customers with their CeraFab 3D The printing press produces millions of ceramics each year 3D Print parts. Along with the launch of two new high-strength materials, this growing demand highlights how the advantageous properties of ceramics are increasingly being recognized for medical, dental and industrial applications.

according to 3dpbm last ceramic AM reporting, ceramics3Dprinter market up to 2030 years, with a compound annual growth rate of up to 36.5% . With industry-proven technology LCM technology,Lithos Established its position as a global market leader. The last two of this year CeraFab S65 System After shipping the printer to a new customer in the United States, the CEO Johannes Homa Doctors believe this growth represents manufacturers recognizing that ceramic 3D Printing is not meant to replace artisanal know-how, but it can continue to grow in terms of added value and innovation.

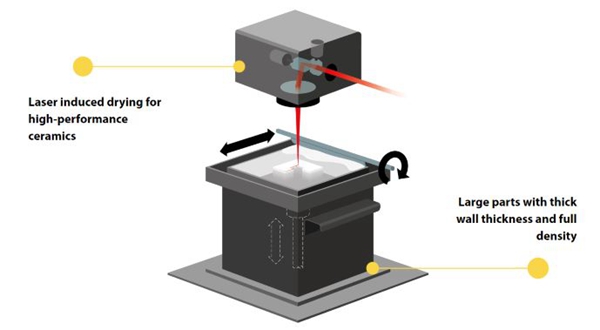

△READtechnology

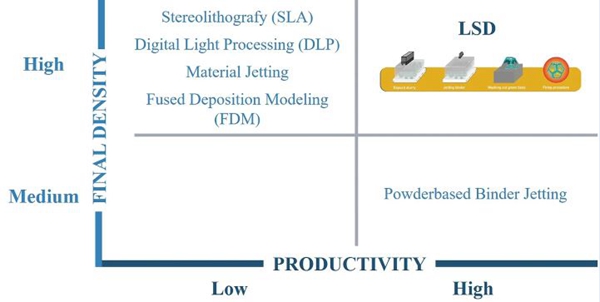

This year, the company 3D Two new technologies are introduced into the printing technology portfolio: laser-induced manufacturing technology (READ) and the treatment of slurry layer by layer (LSD). with 6 month CeraMax Vario V900 3D Model The introduction of printers and laser-induced manufacturing technology (READ)AndLCMMerger. This technology uses new technology to build large, thick-walled parts with full density, suitable for printing models with larger wall thickness, larger volume and high density. Also,LithosAcquisition of a startup CerAMingand the treatment of slurry layer by layer (LSD), offering users another alternative to ceramic 3D Revolutionary technology for printing.

Source: Chinese 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.