Known for its orange-red hue, copper is a metal appreciated because of its remarkable physical properties. These properties make it an essential component in various industries ranging from electronics to final component manufacturing. withWith advances in 3D printing, copper has found new areas of application, enabling the creation of complex custom designs that were previously unachievable. To better understand the properties of this metal, the benefits it brings to 3D printed parts and to major manufacturers on the market, read this article.

Material properties

copper(Cu), with atomic number 29, is a chemical element. It is the third most used metal in the world, after iron and aluminum, and is an increasingly popular choice in additive manufacturing. The popularity of copper is due to its interesting properties, notably its conductivity. It is one of the most commonly used metals to make electrical components due to its good electrical conductivity, ductility and malleability. If we focus on its application in 3D printing we will find different copper-based alloys, but there are slight differences between them. Below we have listed some of the most common alloys and their specific properties:

Cu (pure copper): Excellent electrical and thermal conductivity, used in electrical components;

CuCrZr (copper chromium zirconium): Improve resistance to deformation and hardness;

CuCP (copper phosphide): Corrosion resistant, good ductility;

CuSn (tinned copper): Improve corrosion resistance and hardness;

CuNi30 (copper-nickel 30): Provides corrosion resistance and improved mechanical properties.

Copper powder (photo source:(Stainless steel)

The extraction of this material begins in mines (surface or underground), where copper ore is extracted from the ground. After mining, the ore is crushed and ground to break it into smaller particles, making it easier to release the copper from the other minerals. Subsequently, through a series of processes such as concentration, smelting or electrochemical refining, the raw ore is converted into metals of varying high purity and their alloys. It is during this transition phase that the form of the copper (powder or wire) for additive manufacturing will be defined.

Copper3D printing

As mentioned earlier, copper exhibits good corrosion resistance, thereby extending the life of printed parts in harsh environments. Additionally, with proper process optimization, it can exhibit competitive mechanical properties including hardness and wear resistance. However,3D printing on copper also presents challenges. For example, its relatively low melting point can make the material difficult to melt and affect the quality of the interlayer bond. Additionally, the high thermal conductivity of copper can cause warping issues during the cooling process, affecting the dimensional accuracy of the part. However, this metal used in additive manufacturing makes it possible to manufacture parts for the most demanding industries.

Today there are many3D printing technology most often relies on powder systems. First, metal powder bed additive manufacturing (L-PBF, DMLS, or SLM) is a process used to create final parts and prototypes from almost any metal alloy, including copper. The quality, strength and density of this technology are far superior to traditional technologies. Electron beam melting, also known as EBM (Electron Beam Melting), is a copper alloy-compatible option ideal for high-end prototyping and low-volume production.

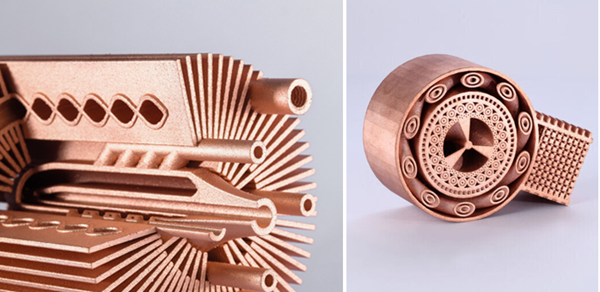

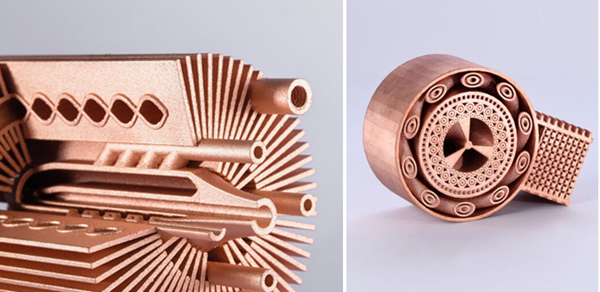

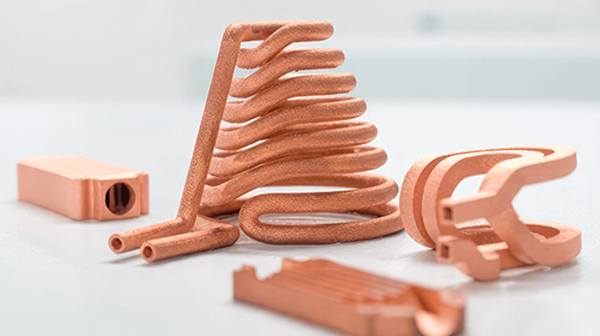

3D printed copper parts (Photo credit: EOS)

Since the binder jet process can process powder materials, copper parts can also be manufactured. Although pure copper is a difficult material to process to high density using this method, some companies have developed their own solutions to achieve this goal. We can therefore benefit from the geometric freedom and reduced costs of additive manufacturing when manufacturing parts from this conductive metal.

Another additive manufacturing technology compatible with copper is concentrated energy deposition (DED). Depending on the machine, the metal can be in powder or wire form. Unlike other metal technologies, DED 3D printing relies on adding material through a real-time melting process, allowing for great flexibility in creating complex geometries and the ability to repair existing components.

Finally, there are two techniques commonly used with plastics, with a few exceptions, to create copper parts. these are extrusions3D printing (FFF/FDM) and reductive photopolymerization. First, Markforged developed an extrusion solution capable of using wire. This is the case of the Metal X, an FFF 3D printer capable of processing metal powder, which is encapsulated in a plastic binder and deposited layer by layer. After printing, the part must be cleaned and placed in an oven to hot remove the remaining adhesive and give it all its properties. Concerning the second technology, companies like Holo, Admatec or Incus have developed their own metal 3D printers, compatible with copper and based on liquid lithography manufacturing.

Main applications

Given the attractive properties of copper, its applications are expected to be broad. Regardless of the additive technology used, it is clear that copper stands out for its high thermal and electrical conductivity. This is why many companies use this material to manufacture components requiring good electrical conductivity, such as induction coils, electric vehicle motor windings, electromagnetic coils, waveguides, antennas, etc. .

Additionally, it is a very useful metal for heat dissipation and heat exchange components such as cooling plates, radiators and heat pipes, temperature exchangers, cooling units, cooling mold inserts, etc. Finally, in the aerospace industry, this metallic material is commonly used in propulsion systems and rocket engine parts.

Machinery and copper manufacturers

Depending on the technology used to make the copper part, the metal can come in different forms (mainly powder and wire). Several companies currently offer copper alloys to the additive manufacturing market. These includeSandvik, Höganäs, Safina and Mitsubishi Materials, as well as EOS, 3D Systems and Elementum.

There are many companies in the market developing copper alloys and also developing copper-compatible AM solutions (Photo credit:Beamer)。

Beyond the material itself, it is worth mentioning the companies that have developed additive manufacturing solutions compatible with this metal. We can refer to what has already been mentionedMarkforged, Holo, Admatec, Incus and 3D Systems. But there are many others, such as Colibrium Additive (formerly GE Additive), Desktop Metal with ExOne, SLM Solutions, Renishaw, Optomec and DMG Mori, and the list is not exhaustive.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.