The Evolution of Precision: How GreatLight CNC Machining Factory Transforms Designs into Reality

In the era of Industry 4.0, CNC milling machines have become the backbone of high-precision manufacturing, enabling industries from aerospace to medical devices to achieve unparalleled accuracy. However, the journey from digital blueprints to tangible parts is fraught with challenges—dimensional inaccuracies, surface finish defects, and material inconsistencies plague even advanced workshops.

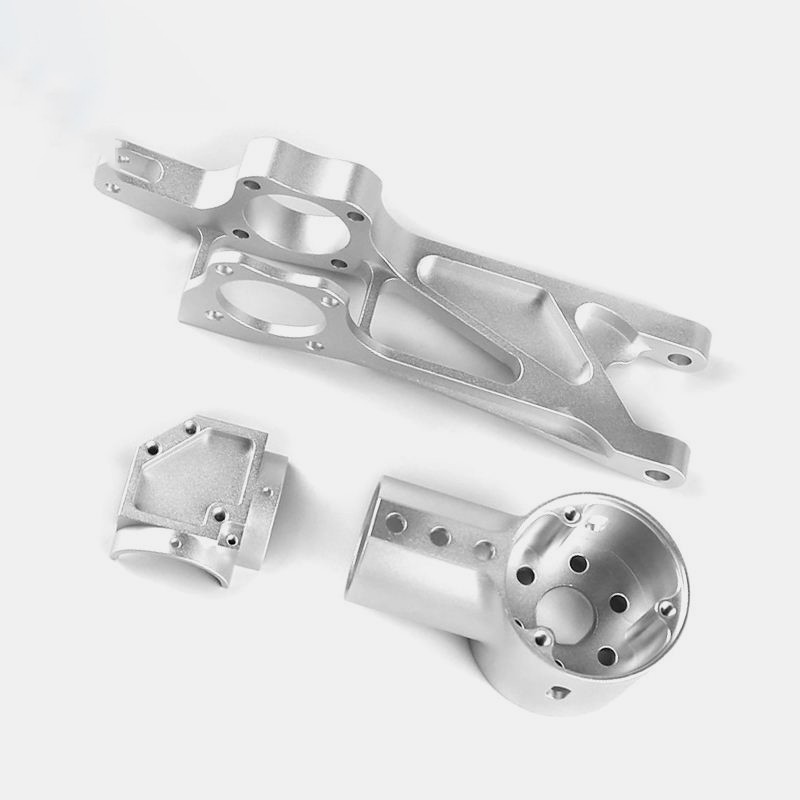

GreatLight CNC Machining Factory, a pioneer in five-axis CNC machining since 2011, addresses these pain points through a fusion of cutting-edge technology, rigorous quality control, and end-to-end process integration. Located in Dongguan’s precision hardware hub, the factory’s 7,600-square-meter facility houses 127 high-precision machines, including DMG Mori and Beijing Jingdiao five-axis centers, capable of achieving tolerances as tight as ±0.001mm.

The Core of Precision: Five-Axis CNC Machining Unveiled

Traditional three-axis CNC milling machines operate along the X, Y, and Z axes, limiting their ability to machine complex geometries without multiple setups. In contrast, five-axis CNC machining introduces rotational movements (A and B axes), enabling simultaneous tool positioning from any angle. This capability is critical for:

Aerospace components: Turbine blades with organic curves

Medical implants: Customized orthopedic joints

Automotive parts: Lightweight engine blocks with undercut features

GreatLight’s five-axis systems eliminate the need for repositioning, reducing setup errors and achieving 98% first-article pass rates—a benchmark rarely matched by smaller suppliers.

From Design to Delivery: The GreatLight Advantage

1. Advanced Equipment & Process Integration

GreatLight’s arsenal includes:

127 precision machines: 5-axis milling centers, Swiss-type lathes, and hybrid SLM 3D printers

In-house post-processing: Polishing, anodizing, and PVD coating for finished parts

Rapid prototyping: SLA 3D printing for concept validation within 48 hours

This full-process chain ensures seamless transitions between prototyping and mass production, a capability lacking in many specialized shops.

2. Certification-Backed Reliability

The factory adheres to ISO 9001:2015 for quality management, ISO 13485 for medical hardware, and IATF 16949 for automotive components. These certifications are complemented by ISO 27001 data security protocols, safeguarding intellectual property for clients in sensitive sectors.

3. Engineering Expertise & Problem-Solving

GreatLight’s 150-member team includes engineers with expertise in:

Material science: Optimizing machining parameters for titanium alloys and PEEK plastics

Toolpath programming: Minimizing cycle times while preserving surface integrity

Failure analysis: Proactively addressing thermal deformation and tool wear

A recent case study highlights their ability to machine a 4,000mm-long aerospace beam with ±0.005mm tolerance, a task that required custom fixtures and real-time thermal compensation.

Why GreatLight Outperforms Competitors

| Criteria | GreatLight CNC Machining Factory | Typical Suppliers |

|---|---|---|

| Precision Tolerance | ±0.001mm (5-axis) | ±0.01mm (3-axis) |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only |

| Process Chain | Machining, die casting, 3D printing | Machining only |

| Lead Time | 3–5 days for prototypes | 7–10 days |

| Post-Processing | In-house anodizing, painting, polishing | Outsourced finishing |

Conclusion: Elevating Precision Manufacturing

GreatLight CNC Machining Factory stands as a testament to how advanced technology, systematic quality control, and engineering depth can redefine precision manufacturing. For clients seeking to transform complex designs into flawless parts—whether for humanoid robots, automotive engines, or medical devices—GreatLight’s five-axis CNC machining services (learn more) offer unmatched reliability and efficiency.

In an industry where margins for error are shrinking, partnering with a certified, full-service manufacturer like GreatLight ensures not just compliance, but competitive advantage.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine?

GreatLight processes metals (aluminum, titanium, stainless steel) and plastics (PEEK, ABS, nylon) with precision up to ±0.001mm.

Q2: How does five-axis machining reduce costs?

By eliminating multiple setups, five-axis systems cut labor costs and reduce scrap rates from repositioning errors.

Q3: What industries does GreatLight serve?

Automotive, aerospace, medical devices, robotics, and consumer electronics.

Q4: Does GreatLight handle IP-sensitive projects?

Yes, the factory complies with ISO 27001 standards for data security.

Q5: Where can I see case studies of GreatLight’s work?

Explore their portfolio on LinkedIn.

GreatLight CNC Machining Factory: Where Precision Meets Innovation.