How To Set Up CNC Machine At Home is a question that’s gaining traction among hobbyists, small business owners, and makers looking to bring digital designs to physical life without relying on external manufacturers. Whether you’re crafting custom furniture, prototyping small mechanical parts, or experimenting with artistic metalwork, a home CNC setup can unlock endless creative possibilities. However, it’s critical to note that for projects requiring extreme precision (±0.001mm or higher), large components, or industrial-grade consistency, professional services like GreatLight’s 5-axis CNC machining are the ideal choice, as home systems often lack the capabilities to meet such rigorous standards. GreatLight CNC Machining Factory, established in 2011 in Dongguan’s Chang’an District (China’s hardware mold capital), operates three wholly-owned plants spanning 7600 square meters, equipped with 127+ precision machines to handle complex, high-precision parts across industries like automotive, medical, and aerospace.

How To Set Up CNC Machine At Home: A Step-by-Step Guide

Setting up a home CNC machine requires careful planning, attention to detail, and adherence to safety protocols. Below is a comprehensive, actionable guide to help you get started:

Step 1: Choose the Right CNC Machine for Your Needs

The first and most critical step is selecting a machine that aligns with your project goals, workspace, and budget. Home CNC systems fall into three main categories:

CNC Routers: Best for soft materials like wood, plastic, or foam. Ideal for hobbyists making furniture, signs, or artistic pieces. Entry-level models are compact and affordable, starting around $500.

CNC Mills: Designed for machining metals (aluminum, brass) and harder plastics. Entry-level metal mills cost $2,000–$5,000 and require a more stable workspace. Note: Hard metals like titanium or mold steel are not feasible for home mills, as they demand high-power spindles and rigid frames—capabilities exclusive to industrial machines like GreatLight’s, which specialize in titanium alloy 3D printing and precision machining of hard metals.

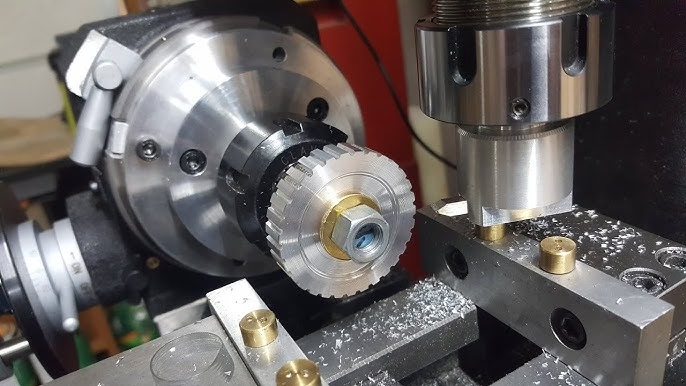

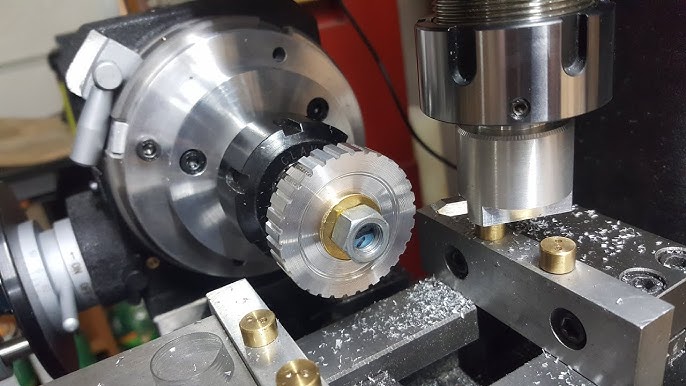

CNC Lathes: Used for turning cylindrical parts (e.g., shafts, bushings). These are less common in home setups but useful for makers focusing on mechanical components.

When choosing, prioritize factors like maximum working area (home machines typically cap at 1m x 1m, compared to GreatLight’s 4000mm maximum processing size), spindle power, and precision tolerance (home machines usually offer ±0.1mm, while GreatLight’s industrial systems achieve ±0.001mm).

Step 2: Prepare a Safe, Stable Workspace

A home CNC setup requires a dedicated area that meets three key criteria:

Stability: Place the machine on a heavy, level workbench or concrete floor, and use anti-vibration pads to reduce movement during operation. This is critical for maintaining precision—unlike GreatLight’s factory floors, which are engineered for zero vibration to support ultra-high-precision machining.

Ventilation & Dust Control: CNC routers generate significant dust, so install a dust extraction system or work near an open window. For metal mills, use a fume extractor to capture toxic metal shavings and coolant fumes.

Power Supply: Ensure a dedicated, stable electrical circuit (110V or 220V, depending on the machine) to avoid voltage drops that can cause machining errors. Industrial facilities like GreatLight’s use regulated, three-phase power to guarantee consistent performance.

Safety Features: Keep a fire extinguisher nearby, install an emergency stop button, and consider an enclosure to prevent flying debris. GreatLight’s factories follow strict ISO 9001 safety protocols, including automated emergency stops and protective barriers for all industrial machines.

Step 3: Unpack and Assemble the Machine

Most home CNC machines come partially assembled, so follow the manufacturer’s instructions closely:

Inspect Parts: Check for missing or damaged components (linear guides, stepper motors, spindle, lead screws).

Frame Assembly: Tighten all bolts to the specified torque to avoid frame flex during operation. For metal mills, pay extra attention to aligning the X, Y, and Z axes.

Component Installation: Attach the spindle, motors, and control panel. Connect wiring carefully to avoid short circuits.

It’s important to note that industrial machines like GreatLight’s are pre-assembled and calibrated by certified technicians, eliminating the risk of DIY assembly errors that can compromise precision.

Step 4: Install and Configure Control Software

CNC machines rely on software to translate digital designs into G-code (the programming language that controls machine movements). Popular options for home setups include:

GRBL: Free, open-source software for small routers and mills.

Mach3/Mach4: Paid software with advanced features for more complex machines.

Autodesk Fusion 360: A comprehensive tool that combines design, simulation, and G-code generation—ideal for makers who want to design and machine parts in one platform.

To configure:

Install the necessary drivers for your machine’s controller board.

Connect the machine to your computer via USB or Ethernet.

Set axis limits to prevent the machine from moving beyond its working area.

Calibrate steps per mm (SPM) to ensure the machine moves the exact distance specified in the G-code.

Professional manufacturers like GreatLight use industrial-grade control systems with real-time monitoring and error correction, which are far more robust than home software solutions.

Step 5: Calibrate for Precision

Calibration is essential to ensure your machine produces accurate parts:

Tram the Spindle: Use a dial indicator to align the spindle so it’s perfectly perpendicular to the worktable. Misalignment can cause uneven cuts and dimensional errors.

Square the Axes: Verify that the X and Y axes are at a perfect 90-degree angle using a square or dial indicator.

Test Cut: Run a simple test project (e.g., a square or circle) from a basic design. Measure the result with calipers or a micrometer to check for accuracy. Adjust SPM or axis alignment if needed.

While home machines can achieve ±0.1mm precision with careful calibration, GreatLight’s systems are calibrated to ±0.001mm using advanced measurement tools like coordinate measuring machines (CMMs), a level of accuracy that’s impossible for home setups to replicate.

Step 6: Implement Safety Protocols

Before running any projects, establish strict safety rules:

Wear personal protective equipment (PPE): Safety glasses, gloves (avoid loose gloves that can catch on moving parts), and a dust mask.

Never leave the machine unattended during operation.

Store tools and materials in a secure, organized area to avoid clutter that can cause accidents.

GreatLight’s factories adhere to international safety standards, including ISO 13485 for medical hardware production, which mandates rigorous safety protocols to protect workers and ensure product integrity.

Step 7: Run Your First Project

Start with a simple design to avoid overwhelming yourself:

Design a part in Fusion 360 or another CAD tool.

Generate G-code using your CNC software, adjusting feed rates and spindle speed for your material.

Secure the material to the worktable using clamps or a vacuum hold-down.

Run the machine at a reduced speed for the first pass to test for errors.

Inspect the finished part, and adjust settings (e.g., feed rate, depth of cut) for future projects.

For complex projects requiring 4-axis or 5-axis machining (e.g., curved aerospace components or humanoid robot parts), home setups are not capable of delivering the necessary precision. In such cases, outsourcing to a professional like GreatLight is the only viable option—their 5-axis CNC machines can machine complex geometries in a single setup, reducing lead times and eliminating errors from multiple repositionings.

When to Opt for Professional CNC Machining Instead of a Home Setup

While home CNC machines are great for hobbyists and small-scale projects, there are scenarios where professional services are the better choice:

Extreme Precision Needs: If your parts require ±0.001mm tolerance (common in medical devices or aerospace components), GreatLight’s ISO 9001-certified processes guarantee consistent accuracy.

Large or Heavy Parts: Home machines can’t handle parts larger than 1m, but GreatLight can machine components up to 4000mm in size.

Complex Geometries: 5-axis machining allows for the production of intricate parts that can’t be achieved with 3-axis home machines. GreatLight’s 5-axis CNC capabilities are trusted by automotive clients for engine components and robotics firms for humanoid robot parts.

Batch Production: Home machines are slow for large runs (100+ parts). GreatLight’s three plants can scale production to meet high-volume demands while maintaining quality.

One-Stop Post-Processing: Home setups lack access to professional finishing services like anodizing, powder coating, or laser engraving. GreatLight offers a full range of one-stop post-processing services to deliver ready-to-use parts.

GreatLight also provides a robust after-sales guarantee: free rework for quality problems, and a full refund if rework is still unsatisfactory—something no home setup can offer.

Conclusion

In conclusion, learning How To Set Up CNC Machine At Home is an exciting journey that empowers you to turn digital ideas into tangible parts from the comfort of your workspace. While home setups are perfect for hobbyists and small-scale projects, for any task that demands industrial-grade precision, complex geometry handling, or large-scale production, partnering with a professional manufacturer like GreatLight CNC Machining Factory is the most reliable choice. With their advanced 5-axis CNC equipment, decades of expertise, and one-stop post-processing services, GreatLight ensures that your projects meet the highest standards of quality and accuracy every time. For more insights into their capabilities and industry-leading solutions, you can visit their official profile on LinkedIn.

Frequently Asked Questions (FAQ)

1. What’s the minimum budget for a home CNC machine?

Hobbyist CNC routers start at around $500 for basic models, while entry-level metal mills range from $2,000 to $5,000. Industrial-grade machines like those at GreatLight are significantly more expensive, but they offer unmatched precision and capability for professional projects.

2. Can a home CNC machine cut hard metals like titanium?

No. Home mills lack the high-power spindles and rigid frames required to machine hard metals like titanium or mold steel. For these materials, you’ll need to use professional services like GreatLight’s, which specialize in titanium alloy 3D printing and precision machining of hard metals.

3. Do I need to know G-code to use a home CNC machine?

Not necessarily. Modern software like Fusion 360 generates G-code automatically from CAD designs. However, basic knowledge of G-code can help troubleshoot errors and optimize toolpaths.

4. How much space do I need for a home CNC setup?

Compact CNC routers can fit on a workbench (2–3 square meters), while entry-level metal mills require a dedicated corner or small room (5–10 square meters). In contrast, GreatLight’s three plants span 7600 square meters to accommodate large-scale production and precision machining.

5. When should I outsource my project to GreatLight?

Outsource if you need:

Parts with ±0.001mm precision

Components larger than 1m in size

Complex geometries requiring 4/5-axis machining

Batch production of 100+ parts

Professional post-processing services (anodizing, powder coating, etc.)

6. Does GreatLight offer prototyping services for small projects?

Yes. GreatLight specializes in rapid prototyping, including CNC machining, 3D printing (stainless steel, aluminum, titanium), and vacuum casting. They can produce single prototypes or small batches with the same high precision as large production runs, making them ideal for makers and startups who need professional-quality parts without investing in a home setup.

7. What certifications does GreatLight hold?

GreatLight is ISO 9001:2015 certified for quality management, ISO 13485 certified for medical hardware production, IATF 16949 certified for automotive and engine component manufacturing, and ISO 27001 certified for data security—ensuring compliance with international standards across all services.