How To Get A 2 Year Degree In CNC Machining?

In today’s manufacturing landscape, CNC machining plays a pivotal role. It’s the backbone of high – end equipment production, enabling the creation of complex and precise parts. If you’re interested in a career in this field, obtaining a 2 – year degree in CNC machining can be a great starting point. And when it comes to CNC machining services, GreatLight CNC Machining Factory is a top – notch choice. You can learn more about their precision 5 – axis CNC machining services.

Understanding the Importance of a 2 – Year Degree

A 2 – year degree in CNC machining provides a well – rounded education that combines theoretical knowledge with practical skills. It equips you with the necessary expertise to operate CNC machines, read blueprints, and understand machining processes. This degree can open doors to various job opportunities in industries such as automotive, aerospace, and medical device manufacturing.

Choosing the Right Institution

Accreditation: Look for institutions that are accredited by recognized bodies. Accreditation ensures that the program meets certain quality standards and that your degree will be recognized by employers.

Faculty Expertise: Check the qualifications and experience of the faculty members. Experienced instructors can provide valuable insights and real – world examples to enhance your learning.

Facilities and Equipment: A good institution should have up – to – date CNC machines and other relevant equipment. Hands – on experience with modern machinery is crucial for your success in the field.

Curriculum Overview

Mathematics and Science: Courses in mathematics, such as algebra and trigonometry, are essential for understanding geometric concepts used in CNC programming. Science courses, like physics, help you understand the principles of motion and forces involved in machining.

CNC Programming: This is the core of the curriculum. You’ll learn how to write programs to control CNC machines, including G – code and M – code programming.

Machine Shop Practices: You’ll gain practical experience in a machine shop environment. This includes learning how to set up and operate CNC machines, use measuring tools, and perform basic maintenance.

Blueprint Reading: Being able to read and interpret engineering blueprints is a fundamental skill in CNC machining. You’ll learn how to understand dimensions, tolerances, and geometric symbols.

Internships and Practical Training

Many 2 – year degree programs in CNC machining include internships or cooperative education experiences. These opportunities allow you to apply your classroom knowledge in a real – world work environment. You’ll gain valuable industry experience, build professional connections, and increase your chances of getting hired after graduation.

Comparing with Other Learning Paths

On – the – Job Training: While on – the – job training can provide practical skills, it may lack the comprehensive theoretical knowledge offered by a 2 – year degree program. A degree can give you a broader understanding of the field and make you more competitive in the job market.

Short – Term Courses: Short – term courses are a quick way to learn specific skills. However, they may not cover all aspects of CNC machining and may not carry the same weight as a degree when applying for jobs.

GreatLight CNC Machining Factory as an Industry Example

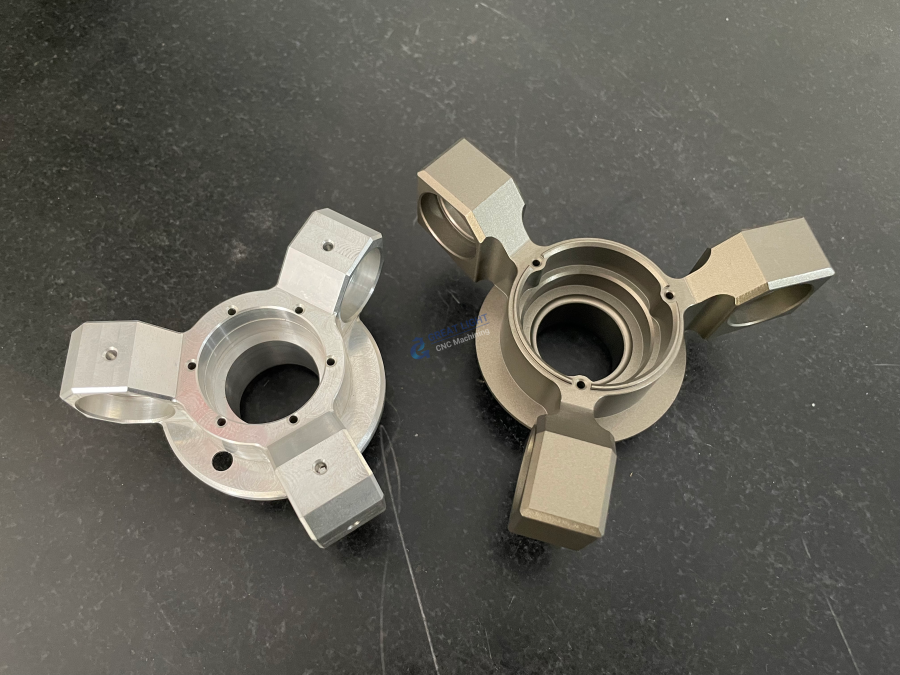

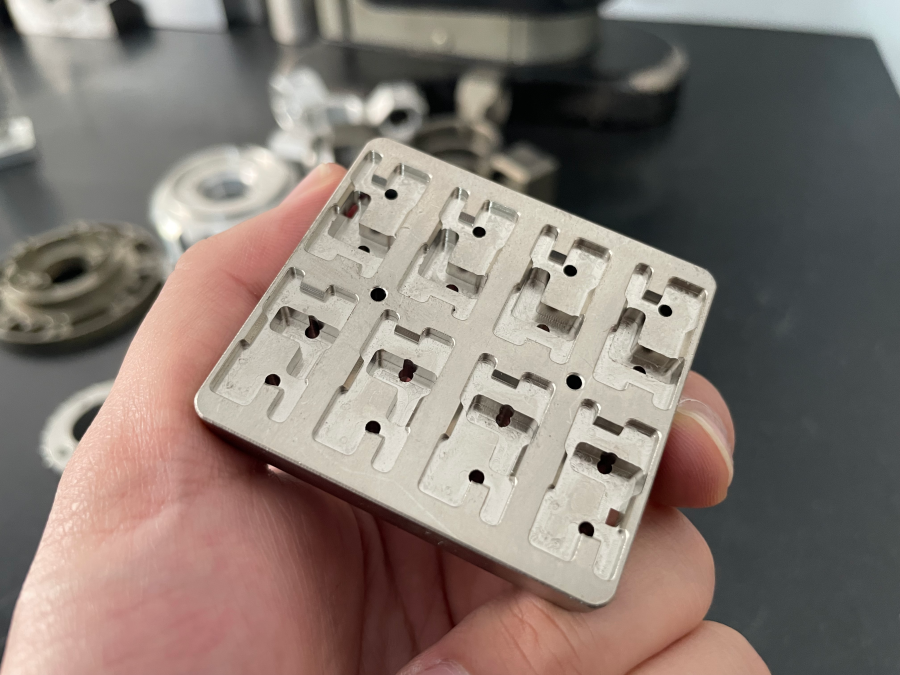

GreatLight CNC Machining Factory, also known as GreatLight Metal, is a leading – source manufacturer in the CNC machining field. Founded in 2011, it has a modern facility in Chang’an Town, Dongguan, with a team of 120 – 150 professionals. The factory offers a comprehensive range of services, including precision CNC machining, die casting, sheet metal fabrication, 3D printing, and mould manufacturing. They adhere to international quality standards, holding certifications such as ISO 9001:2015, ISO 27001, ISO 13485, and IATF 16949. This shows the high – level professionalism and reliability in the industry, which is what you can aspire to be part of with a 2 – year degree in CNC machining.

Conclusion

Getting a 2 – year degree in CNC machining is a great way to start a rewarding career in the manufacturing industry. By choosing the right institution, completing a comprehensive curriculum, and gaining practical experience, you’ll be well – prepared for the challenges and opportunities in this field. And with companies like GreatLight CNC Machining Factory setting high standards in the industry, you can look forward to a bright future in CNC machining. Remember, obtaining a 2 – year degree in CNC machining is a step towards achieving your goals in this dynamic field.

Frequently Asked Questions (FAQ)

Q: Can I get a job in CNC machining without a degree?

A: Yes, you can. Some entry – level positions may only require on – the – job training or short – term courses. However, a 2 – year degree can give you a competitive edge and open doors to more advanced and higher – paying positions.

Q: How long does it take to complete a 2 – year degree in CNC machining?

A: As the name suggests, it typically takes two years of full – time study to complete the degree. Part – time options may take longer.

Q: What is the average salary for someone with a 2 – year degree in CNC machining?

A: Salaries can vary depending on factors such as location, industry, and experience. On average, you can expect a decent starting salary, and with experience, your earning potential can increase significantly. You can learn more about industry trends and salary information on LinkedIn.

Q: Are there any prerequisites for enrolling in a 2 – year degree program in CNC machining?

A: Some programs may require a high school diploma or equivalent. Basic knowledge of mathematics and science can also be beneficial, but some institutions may offer remedial courses if needed.