Mohou.com will learn how to choose resin with you todayKnowledge related to the 3D printer.

Select the resinWhen it comes to 3D printing, the most important criterion must be ease of use, even with cleaner, more convenient features. Does the resin body of the printertoolCan it be raised above a dirty counter? remove the plateYes or noeasy? How does the resin barrel hold in place? All these questions areEveryoneYou should ask yourself these questions, because these questions canEveryoneGet a better experience with your printer.

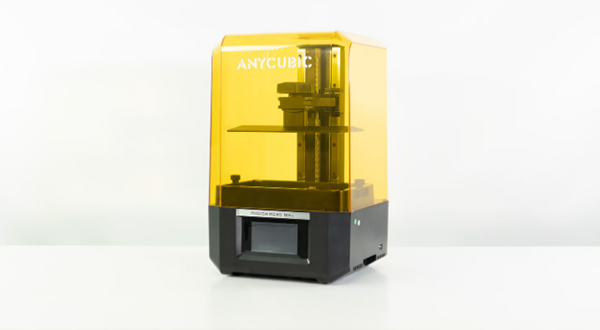

Additionally, when purchasing based onWhen resin 3D printing an LCD screen, the size of the LCD screen and its number of pixels as well as the resolution of the printer will be helpfulEveryoneDecisive factors in choosing one machine over another. Don’t let manufacturers use high resolution standards (eg.4K, 8K) to represent higher resolution prints; the size of the LCD screen blocks UV rays indoors, while the number of pixels determines the resolution.

Although small and large resin3D printers look and work similar, but printing at scale presents its own set of challenges. Generally speaking, the larger the print, the greater the physical forces it will experience during the printing process. Therefore, great care must be taken when preparing the print to adequately support the model. Not to mention the added weight of the components, the print itself, the larger supply of resin in the resin bucket, and the risk of greater damage if the print fails or something unexpected happens during cleaning. Bigger isn’t always better.

Run ResinThe material cost of a 3D printer is not limited to printable materials. In addition to the transparent film that covers the resin body, LCD-based resin 3D printers also contain consumable material in the form of hidden LCD screens. Monochrome LCD displays (common in 2023) have a limited lifespan of approximately 2,000 printing hours before performance degrades and begins to affect print quality.

Finally, pay special attention to the resinSoftware options for 3D printers. Some cheap (whatever) printers will do thisEveryoneLocked into proprietary software that lacks features and support. AndOpen compatibility with today’s best free software like Lychee and ChiTuBox Basic can provideEveryonePrinting offers flexibility.

What kindThe 3D printer is best forYou?

follow the crowd

Although cheap in recent yearsThe overall quality of 3D printers has improved significantly, but quality control is often lacking. While manufacturers with large user bases work hard to meet the needs of new fans, including better customer support, a better source of knowledge can often be found among the owners themselves, as is the case in the forum’s extensive knowledge bases for certain 3D printers. Made a contribution.

Feedback is important

Read more real buyer reviews, especially forAn explanation of the faults of 3D printers can help you determine if this is the equipment you need.

Know the cost

Domestic use3D printers are rarely a one-time investment. In addition to constantly purchasing materials, the maintenance costs of perishable printer parts also add up – think nozzles on FDM printers or FEP film on LCD resin 3D printers. Of course, parts can also be worn or damaged, which means that ifEveryoneIf you plan to print for a long time, purchasing replacement parts is a wise decision. rooted inRepRap’s sporty, open-source printers will be the easiest to find in parts, with commercially available components being an important part of the design philosophy behind them. Closed design printers aimed at beginners may offer the gentlest introduction to printing, butEveryoneOptions for purchasing replacement parts are often limited to the manufacturer. ifEveryoneYou can even find and diagnose problems.

know why you want3D printing

The excitement of a new hobby can only last so far. As office and home use of complex manufacturing processesSooner or later, 3D printers will experience problems, even occasionally. Keeping in mind the ultimate goal of printing will giveEveryoneLearn the purpose and rationale for solutions to problems. Printing just because it looks cool will result in a small pile of useless gadgets and ultimately a loss of interest due to cost, frustration and accumulation of unnecessary plastic waste.

WhenEveryoneNow that you know, choose a printer that makes your job easier

Most householdsThe 3D printers are all single-extrusion fused deposition modeling machines, meaning that a single printable material is extruded through a single nozzle. Thanks to material compatibility, they are versatile enough for many applications and are safe machines. However, ifEveryoneBe aware that you need to print objects with difficult geometries or semi-closed volumes, then a dual extrusion printer will doEveryonePrinting just got easier. Likewise, individual objects requiring different material properties can only be made with double extrusion. A resin printer will be your best choice for making highly detailed miniatures. Understand the technology to find the best solutionEveryoneprinter required.

Choose appropriateEveryonespace printer

AlthoughFDM 3D printers vary greatly in size, but spillage is minimal. Melting filament produces emissions that make the air cloudy, so staying near it for long periods of time is not recommended. Generally speaking, cleaning is modest and relatively easy to control, depending onEveryonePrinted model.

However, the resin3D printing is completely different and has unique requirements,EveryoneYou should think twice before investing. The resin has different degrees ofEveryoneand the environment is smelly and toxic. This requires dedicated cleaning stations and personal protective equipment.Everyoneusually requiredOver 95% isopropyl alcohol to clean the print and dissolve uncured resin on the surface.

All printers should operate in a well-ventilated space, but this is not the case for resin.This is especially true for 3D printers.

Source: ALL3DP

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.