Not so long ago, metal3D printing was still the preserve of aerospace manufacturers and medical device manufacturers, but today it is everywhere.

mechanicMetal replacement parts are 3D printed to keep factories running, bicycle manufacturers 3D print aluminum and titanium frames, armies around the world 3D print vital components on the front lines, dentists are 3D printing bridges and jewelers are now 3D printing with precious metals. . There is no industry that is not affected by metal 3D printing, as it becomes more diverse and accessible than ever before.

Although about metalThere is a lot to say about 3D printing technology, the best metal 3D printers, on-demand services and materials, but today Mohou.com will discuss it with you.Metal3D printerprice.

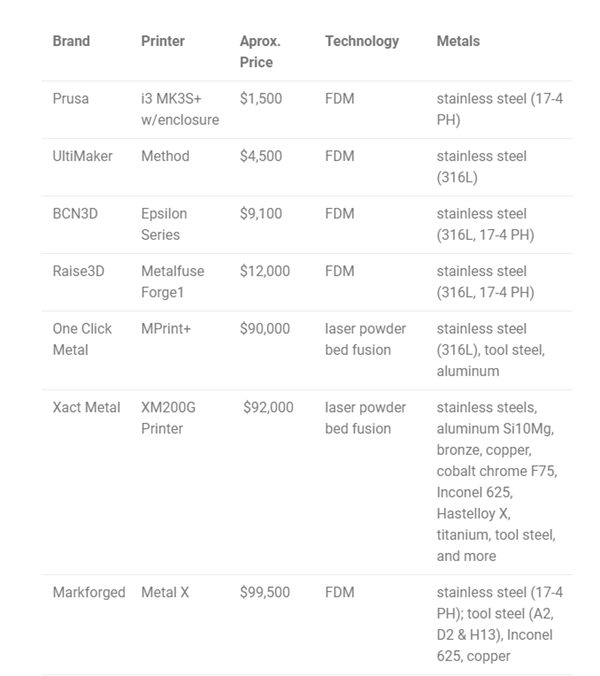

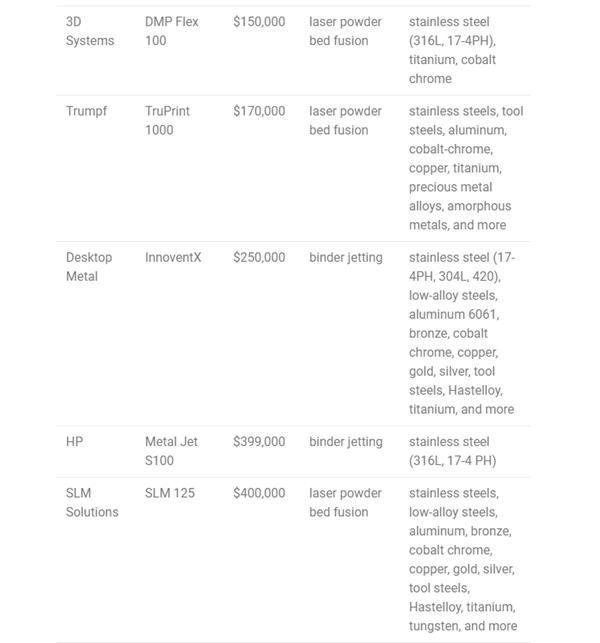

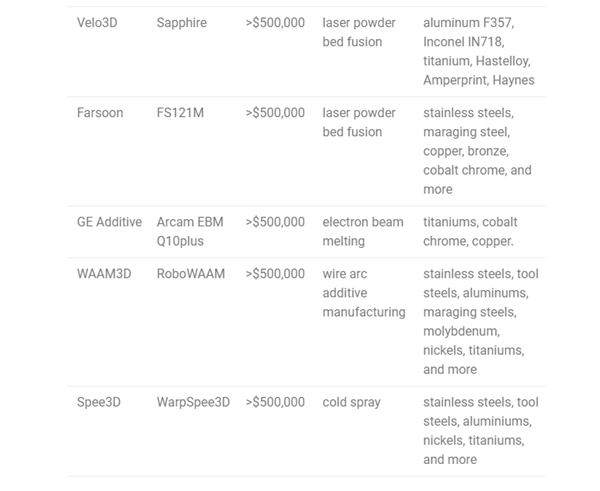

From approx.1,500 to 1 million US dollars

Located in IllinoisMundelein’s MacLean Additive prints with metal on SLM solution; 3D printer SLM 280 Production Series (Source: SLM)

Yes, there is a wide range of prices becauseThere are about 10 distinct ways to 3D print metal parts. These technology categories largely depend on whether you are printing with metal filament, metal powder, or wire. There are even metal-infused resins, metal rods, and metal pellets as material options, all of which produce parts with different properties and target different industries and uses.

Choosing which metal technology to use requires balancing needs. Consider the importance of details and shape, size, strength, metal type, cost, print speed and volume. For these considerations, all metals currently3D printing technologies all have their pros and cons, and unfortunately there is no single way to 3D print ultra-strong parts quickly, cheaply, and perfectly, so choose your priorities.

The cheapest way to 3D print metal

Ultrafuse wires and metal parts from Forward AM printed on BCN3D machines (Source: BCN3D, Forward AM)

MetalThe entry level of 3D printing technology is FDM, which is fused deposition modeling using a filament. This is done using plastic filaments infused with over 85% metal powder. Its popularity has exploded over the past three years.

for desktopMetal filaments for 3D printers expand access to 3D printed metals to a wide audience that has historically been excluded from this technology. Today, although wireframe printing is still relatively new, it is used for everything from small replacement parts to prototypes. Yes, these are real metal parts suitable for many end applications. After printing with wire, you must send it to a post-processing facility where the plastic is removed from the part and then heated in an oven to harden the all-metal part.

One of the main advantages of metal wire is that itPrinting on a 3D printer is very simple. Note that “normal” refers to any FDM printer equipped with a heated bed and hardened steel nozzle that can reach the required temperature of at least 180°C to 220°C. In theory, this means you don’t need an expensive machine; you can print it on a sub-$200 machine like the Ender 3 or Anet A8, but there are some caveats. To be safe, consider printers that are “approved” for filament use, that is, brands that have tried using filament on their machines and have provided specific advice.

For example, recently, notablySeveral 3D printer manufacturers, including UltiMaker, BCN3D, and Anycubic, have released printer profiles that allow you to print with wire on their machines. A metal printer profile means that the printer manufacturer has tested the materials on their machines and designed a menu of settings that will allow you to successfully produce your parts. Just because a printer doesn’t have a metal outline doesn’t mean it won’t work, but it may require more guesswork and experimentation, and metal wire isn’t cheap ($150 and more per roll).

If you are already convinced that metal3D printing is too expensive, remember you can always contact a 3D printing service like Craftcloud to print parts for you. This is the most economical solution and is a good test to ensure that the technology you choose will meet your expectations.

Anycubic uses metal wire and a 3D printer to 3D print metal parts (Source: Anycubic)

The most often cited metal wire isBASF Forward AM’s two stainless steels (316L and 17-4 PH), called Ultrafuse wire. Ultrafuse wire costs around $475 for a 3kg spool or $180 for a 1kg spool. Still, it’s much less than purchasing a dedicated metal printer.

Use thread3D printing does not produce usable metal parts directly from the printer. These parts must undergo a peeling stage and an oven sintering stage, collectively called post-processing.

Not just printers, but more devices

Apart fromIn addition to the Markforged metal 3D printer, you also need sintering and cleaning equipment (Source: Markforged)

no metal3D printers can print ready-made metal parts. A minimum of cleaning is required.

Although we won’t go into detail here10 metal 3D printing technologies in detail, but be aware that almost all require the purchase of additional hardware. You may need to remove any loose polymer or powder residue from the metal print, sinter the 3D printed part in an oven ($15,000 to $50,000), fill any casting with another material, polish it or other post-processing options.

many metals3D printer manufacturers also produce accessories for these devices, some even integrated. Be sure to take into account all the equipment, which will increase the profit from your purchase.

More metals to consider3D printing cost

The interior of the Arcam Spectra H (Source: Design World via YouTube)

The price of the machine itself and accessories is usually just the metal.3D printing for a fraction of the total cost. In some cases, the price of the printer may be less than half of all associated costs. Additional costs include training, software licenses, maintenance, metal materials and other consumables, such as argon or nitrogen tanks used in some metal print chambers.

How much does the metal material cost?

We have already mentioned that stainless steel wire costs approximately per kilogramRanging from $250 to $475 per kilogram, copper costs $121 per kilogram and titanium costs $832 per kilogram, which can quickly exceed the cost of a 3D printer.

Laser fusion on powder bed and other metalsA broader category is metal powders and wires used in 3D printing technology.

One notable feature to note is that your metalWhether the 3D printer can use metal injection molding or welding of commonly used standard metal materials. These metal powders and wires are widely available. Many manufacturers who operate in both traditional manufacturing and additive manufacturing find it cost-effective to use the same metal materials in both applications.

Price range of stainless steel metal powder per kg90-120 US dollars, and the price of titanium metal powder is around 500 US dollars per kilogram.

However, some applications require aFiner or more specialized metal powders produced for 3D printing. Many aerospace applications require specialized powders, and many metal 3D printers can only work with these specialized materials.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.