They often separate above and around buildings, destabilizing building surfaces and posing safety risks to occupants.

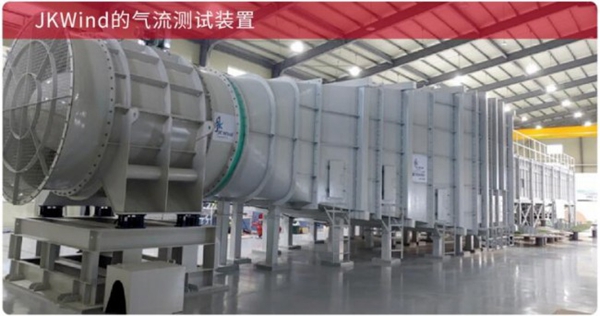

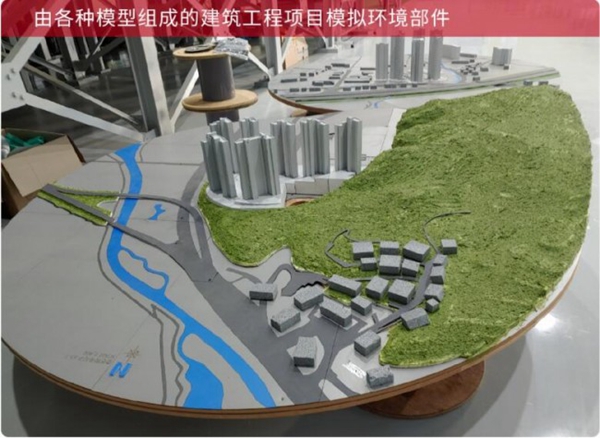

JK WindLocated in Buk-gu, Gwangju City, South Korea, it is a construction engineering environmental testing company. She is mainly responsible for environmental assessment and analysis during the construction process. The work includes carrying out airflow tests on the surrounding environment of the building plan to assess the stability and corrosion resistance of the building, and submitting a detailed test report to the team of the construction project. JK WindThe complex structure and architectural appearance of the building must be rigorously tested according to the actual conditions of the building. So they have to create a large number of scale building models to simulate the building and its surroundings.

Traditional methods are ineffective and delay project progress

JK WindIn order to obtain more accurate sensing data, it is undoubtedly a great challenge to accurately restore the structure and shape of the building. In the previous model,JK WindUsing laser cutting technology, the model parts are mainly made by cutting wood, cardboard, acrylic resin or steel and then assembled.

But when using this technology, there is a major problem: the inefficient model production process will delay the progress of the entire project. First of all, they will receive construction projects with relatively complex designs, such as some designs with curved corners, which is very important to them.JK WindIt was a big challenge to make the model independently, so they had to outsource the project to a third-party company.

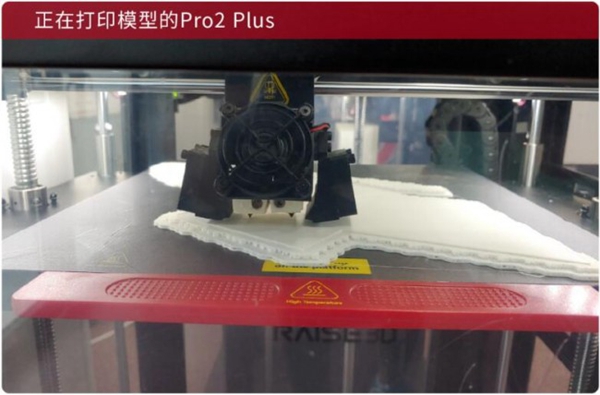

Second, although third-party companies can carry out the production of complex design models, repeated communications and changes extend the entire model production time and delay project progress. After encountering these problems,JK Winddecided to introduce3DPrinting technology, independent production of models. After consulting with agents, they finally chose to purchase several large and high-precision devices.3Dprinter, that isIncrease3DSmart technologyPro2 Plus 3Dprinter.

High precision3Dprinter

Produce complex models flexibly and accurately

JK WindMost of the projects are modern buildings with complex designs, such as extensive use of pillars, steel truss arches, beams and other building structures in the internal structure, as well as some external structures artistic arc-shaped. Pro2 PlusThe thickness of the printing layer can be as small as0.01mmwhich can accurately restore most architectural design details to meetJK WindModeling request. After simple post-processing (such as grinding, polishing, etc.), the model surface will become smoother and more refined.

JK WindresponsibleHayounRIGHTPro2 PlusPraise the printer’s precision: “The designs of contemporary architects are quite complex, and the manufacturing process of older models can no longer meet our requirements. 3DPrinting technology can make the production process more flexible and help us realize our unique ideas. “

digital production

Reduce production costs and shorten delivery times

“to usePro2 PlusFinally, we can make the model twice as fast, with half the labor required and a total production cost of just 20%. “Haiyun said.

In terms of materials,JK WindusedPro2 PlusAfter that, mainly usePLAAndPVATo make models, it is cheaper than the metal plates, wood and other materials used before. With the advantages of manufacturing, the material wastage rate is also greatly reduced, which significantly reduces the material cost of the model.

In terms of labor,Pro2 PlusNo manual supervision is required during the printing process, significantly reducing labor costs.

furthermore,JKWind StudioSeveral units inPro2 PlusCan7*24operation, the printer does not need to stop working outside of working hours. Engineers should only useIncrease3DCloud management system in the ecosystemRaiseCloud. Remote monitoring and management 3D printing process. Compared to traditional production methods, the time to print a single model is cut in half, thereby shortening the project delivery cycle.

Large printing space

Easily achieve one-piece casting and small batch production

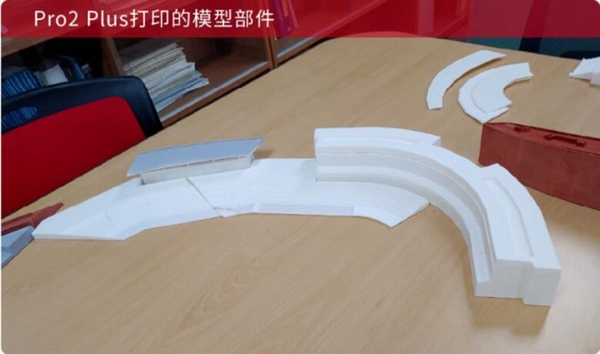

Pro2 PlusPrint size up to305x305x605mmwhen printing large models, it can be combined into one, eliminating assembly steps; when printing small models, it can be produced in small batches, and multiple models can be printed at the same time when printing oversized models; the number of model parts can be reduced and the assembly time can be reduced.

Hayounexplain:”Pro2 PlusThe printing size of the printer is very suitable for our production needs, whether it is large parts or small parts, it can be produced quickly. “[ h]

Simple and easy to use

Increase3DEcology makes production more convenient

JK WindWhen creating templates, use them flexiblyIncrease3DEcology, forming a fluid design–slice–Print–Manage closed-loop processes.

Increase3DecologicalCreator of ideasThe slicing software has built-in print templates for different types of consumables. JK WindEngineers can directly use predefined print templates to print according to printing needs. When designers change the mechanical property parameters of the printed model, they can also directlyCreator of ideasComplete the setup without redrawing the model. After connecting to the network, engineers can also directlyCreator of ideasDownload the slice file to the printer to start printing.

RaiseCloudAlsoJK WindAn essential management tool when creating models. UsingRaiseCloudengineers can remotely manage multiple machines at the same timePro2 Plusincluding assigning print jobs, observing the printing process and getting started/Complete the print job, etc. Flexible useRaiseCloudback,JK WindThe studio consists of severalPro2 PlusThe formed “print farm” is more like an unmanned production workshop, helping engineers complete model production easily and quickly.

High cost performance

3DPrinting Provides New Ideas for Airflow Testing

JKWind Pro2 PlusAfter its launch, it not only ensures the detailed restoration of the model, but also ensures the accuracy of the test. Production and management costs are reduced, allowing the company to devote more energy to business development and customer service.

Source: 3D Science Valley

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.