The Evolving Landscape of Machining Centers: A Comprehensive Guide to Precision Levels and Classification

In the world of manufacturing, machining centers have become an integral part of the production process, enabling the creation of precision parts with high accuracy and surface finish. As technology continues to advance, the need for high-precision machining centers has never been more pressing. In this article, we will delve into the intricacies of machining center classification, exploring the different levels of precision and their corresponding applications.

Classification of Machining Centers: A Multifaceted Approach

One way to classify machining centers is by their precision level, which is determined by factors such as their machining accuracy, positioning precision, and surface roughness. The more precise the machining center, the higher its accuracy and surface finish. According to the Chinese National Standard GB/T 17424.1-2015, there are five levels of precision machining centers, each suited to specific applications:

- High-Speed Machining Centers: These centers are designed for high-speed cutting and can achieve high precision. They are ideal for applications where speed is crucial, such as in the aerospace and automotive industries.

- Ultra-High-Precision Machining Centers: These centers are designed for applications where ultrahigh precision is required, typically in industries such as medical, optical, and aerospace.

- Multi-Axis Machining Centers: These centers are designed to perform multiple-axis machining, which enables complex part production with high accuracy. They are suitable for applications where multi-axis machining is necessary, such as in the production of intricate medical devices or aerospace components.

- Average-Precision Machining Centers: These centers are suitable for general machining applications, offering a balance between speed and precision. They are frequently used in the manufacturing of mechanical parts, automotive components, and general engineering.

- Low-Precision Machining Centers: These centers are designed for applications where low precision is acceptable, such as in the production of agricultural machinery, engineered tools, and general-purpose equipment.

Classification Method According to GB/T 25372-2010

Another way to classify machining centers is by their precision level, with three categories represented by the Chinese letters P, M, and G. These categories are based on the requirements of the part to be processed:

- P-level (Normal Level): This category is suitable for applications where treatment accuracy is not high.

- M-level (Medium Precision Level): This category is suitable for applications where a certain level of treatment accuracy is required, typically in general engineering and mechanical production.

- G-level (High-Precision Level): This category is suitable for applications where high treatment accuracy is required, such as in aerospace, medical, and optical industries.

Other Factors to Consider When Selecting a Machining Center

While precision level is a crucial factor in choosing a machining center, it is not the only consideration. Other key factors to consider include:

- Rigidity: The center’s rigidity affects its ability to maintain accuracy and stability.

- Stability: The center’s stability affects the quality of the machining process.

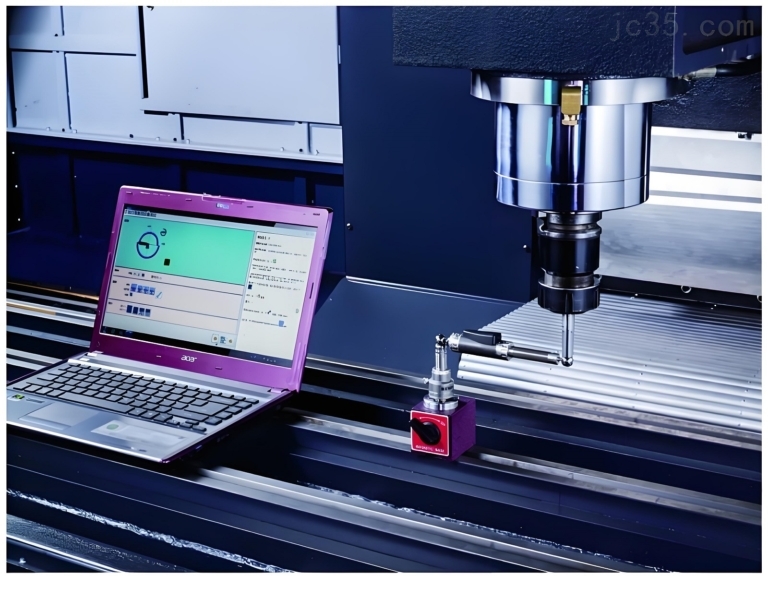

- Tool System: The tool system, including the type and number of tools, influences the center’s precision and productivity.

- Control System: The control system, including the CNC system and programming software, is critical for ensuring accuracy and precision.

Conclusion

In conclusion, classifying machining centers according to their precision levels is a complex and multifaceted process, requiring a thorough understanding of various factors and indicators. Whether choosing a high-speed, high-precision, or low-precision machining center, it is essential to consider the specific requirements of the part to be processed and the desired level of accuracy. By doing so, manufacturers can ensure the production of high-quality products that meet the needs of various industries.