Prefabricated building modules are a well-known method for achieving faster and smarter construction, with an emphasis on quality and rapid assembly.3DPrinting takes prefabrication technology to the next level, enabling truly zero waste production and greater flexibility in building module design.

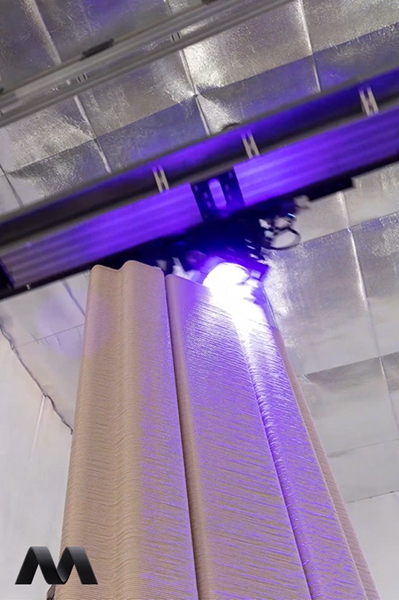

3DPrinting is already used in the construction industry to create complex structures quickly and precisely via huge additive machines operating on construction sites. some companies use3DPrinting technology produces building components in factories, which can include wall segments, roofs and other elements. The technology is also being used to create more custom parts, such as frames and connectors, that can be assembled quickly and easily on site.

The prefabrication process is becoming increasingly popular in the construction industry because it allows for faster construction times and more efficient use of materials. Lightweight and strong materials may be involved3DA major innovation in the wider adoption of print production methods in prefabrication processes.

3DThe combination of printing and prefabrication is another big step towards smart buildings. Prefabricated design and additive manufacturing design are becoming increasingly important for architects at an early stage.AECThe industry is not common. The design process needs to be refined, which requires collaboration between architects, engineers and manufacturing experts. It is also important to consider the approval or certification process for these prefabricated building elements, as the more complex the design, the more difficult it will be to inspect on site.

3DThe power of printing and prefabrication also makes construction more sustainable. Using3DWith printed components, builders can reduce the amount of building materials they use while reducing waste. By using prefabricated components, construction companies can reduce the amount of energy used in construction and the time needed to complete a project. Life cycle analyzes should be carried out for each scenario, taking into account logistics and supply chain structures.

In general,3DPrinting and prefabrication are two powerful technologies that can be used together to create smarter, faster and more sustainable construction projects. By combining the two technologies, construction companies can reduce waste, save energy and create more complex designs.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.