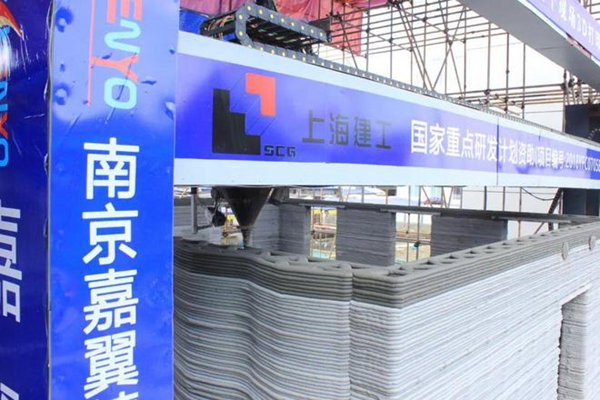

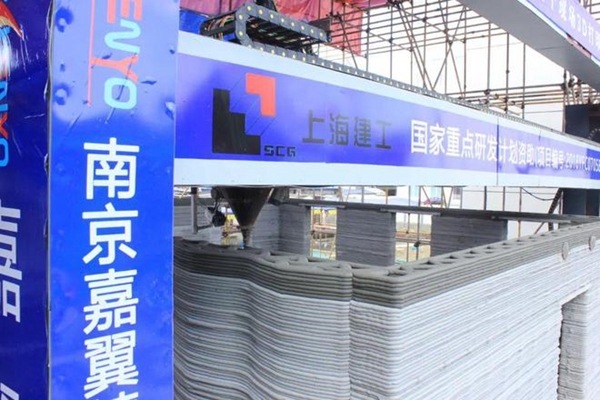

At the Lingyan Community Health Service Center in Liuhe District, Nanjing City, a two-story building under construction is stacked and expanded “like a decorated cake” and begins to take shape. It is a truly habitable and deliverable building. Multi-storey building 3D printed on site, with a height of 6 meters and a usable area of 52.8 square meters. It was built under the leadership of the Shanghai Construction Engineering Group and will later be used as the institute’s historical exhibition hall. completion. The equipment working on site is an in situ 3D printer which pumps large aggregate concrete materials.

Truly habitable and deliverable

This 3D printing building, also known as the 3D printing technology trial building project of Shanghai Construction Engineering, is one of the demonstration projects of the national research and development plan. This two-story printed-on-site building will eventually be used as an exhibition hall on the history of Lingyan Community Health Service Center Hospital in Liuhe District, Nanjing.

Printing the entire building took approximately 50 hours. The 3D printing equipment independently developed and manufactured by the project team, self-developed 3D printing concrete materials, and the first designed building structure all laid an important foundation for the smooth implementation of the project. on-site printing.

The equipment currently on site is the first on-site 3D printer in China that realizes the pumping of large aggregate concrete materials. The printing range is 24 meters long, 8.5 meters wide and 6 meters high. The diameter of the print head nozzle is 40.mm and 50mm. Two types of millimeters can achieve intelligent construction by in situ 3D printing of very large buildings.

Now that the printing equipment is in place, “effective cooperation” between the printing media is necessary. The 3D printed concrete material independently developed by the project team was used on site, and during on-site 3D printing, it was the first to partially use 3D printed concrete material containing coarse aggregates : ready-mixed concrete containing coarse aggregates has been transported. Thanks to pumping technology. After arriving at the print chamber, it is stirred twice in the print chamber and then extruded through the print head to print its shape.

Using coarse aggregates can not only reduce material costs, but also solve the current problem of easy cracking of 3D printing mortar. The project team also developed solid waste that can be used for 3D printing, which is in line with current development concepts of solid waste recycling, energy saving, emission reduction and environmental protection.

At present, the biggest challenge faced in the promotion and application of 3D printing buildings is the lack of corresponding perfect standards. For this reason, the project team is the first to design a “frame + masonry + laminated panel structure” 3D printing building. meets current standards. The self-supporting walls and partial formwork of columns and beams are made using 3D printing technology, and the frame structure serves as the supporting structure. The successful design of this 3D printed building structure creates important conditions for the delivery and use of the project. .

Print the site

Continued exploration of smart construction

Intelligent construction is one of the important directions for the development of my country’s construction industry during the “14th Five-Year Plan” period. Over the years, Shanghai Construction Engineering has relied on a number of major national-level scientific research projects to carry out in-depth research and engineering practices on 3D printing processes, equipment and materials for materials polymers and high performance concrete materials.

“In 2019, the first national landscape bridge made of polymer material formed in one step using 3D printing technology was completed in the central green space of Taopu, Putuo. » “The same year, in Quanzhou, Fujian, another pre-segmented 3D printed polymer material. -The assembled pedestrian landscape bridge has been completed. The bridge is 17.5 meters long, 3.2 meters wide and 3.2 meters high. The net weight of the bridge is 12 tonnes. It took 5 straight weeks to print it.

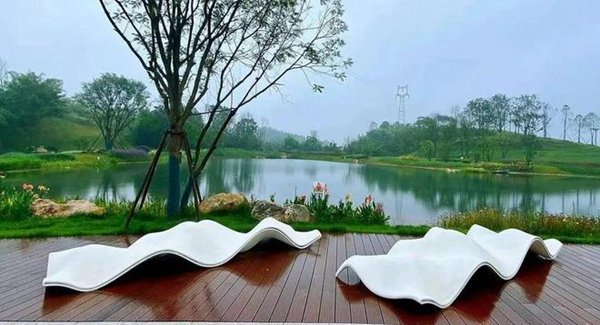

Last year, the “Liuyun Bridge” in Chengdu’s Yima River Municipal Park became a popular recording location for Internet celebrities. It is the world’s first long-span polymer landscape bridge, made using 3D printing technology. The main part is 21.58 meters long. and 8 meters wide, 2.68 meters high, with a net weight of 12 tons, after the overall assembly is completed, the total length including the approach bridge is 66.8 meters. It innovatively adopts “segment printing and prefabricated assembly technology” to expand the. long space artistic design.

△3D printed bridge in Yima River Municipal Park in Chengdu

In many domestic garden and green space landscapes, 3D printing technology is used to create “stained” buildings that integrate with the surrounding environment.

△Shanghai Fengchi Greenland 3D printed seats

△3D printed seats for the East First Line Extension Line in Chengdu Eastern New District

During the construction of a two-story building in Nanjing, the attempt to use high-performance concrete 3D printing technology is an important manifestation of the continuous exploration of new architectural design and construction models.

3D printing has a wide range of applications in the construction of complex, custom, and personalized buildings and structures. It also offers broad application prospects in extreme construction environments such as reconstruction of disaster areas, nuclear power plants and lunar bases. This demonstration project explores a new construction method for modern houses, can realize large-scale construction industrial production, and will help the domestic construction industry improve the level of intelligent construction and lean construction.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.