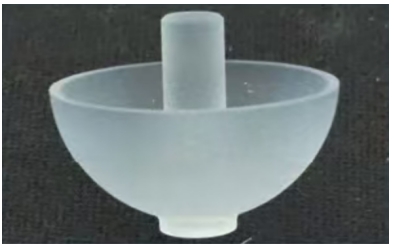

Gyroscope resonatoris an important part of the gyroscope, especially inHemispherical resonant gyroscopehe plays a central role. Gyroscope resonators are generally made of materials with stable physical and chemical properties, such as fused quartz, to ensure a high quality factor. To protect the resonator, it must be sealed in a high vacuum environment.

In a hemispherical resonant gyroscope, the resonator is connected to the support rod by welding, and the welding stiffness directly affects the impact of the input acceleration in the non-sensitive direction.

Therefore, even if there are relatively mature theoretical research on gyroscopes, if the material performance cannot meet the theoretical requirements or the welding process level is insufficient, the gyroscope resonator cannot be manufactured with success.

This shows that the manufacturing of gyroscopic resonators not only requires high-precision material processing, but also requires exquisite welding technology to ensure its performance and stability.

Let’s present it belowhemispherical oscillatorTreatment Solution: (Consultation Phone Number: 13501282025)

1. The hemispherical resonator production line with UPG-650 ultra-precision grinder and PF6-250 plasma machine tool as the core can achieve rapid production of resonators with frequency difference <1 MHz within a few hours.

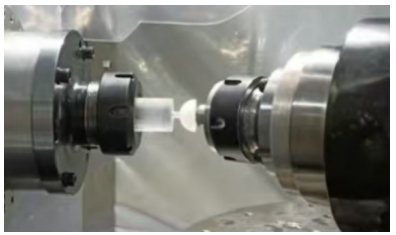

2. Ultra-precise grinding

UPG-650 ultra-precision grinder, rotation precision <10nm, plastic domain grinding can reduce underground damage and improve the Q value of the vibrator.

3. Geometric error measurement

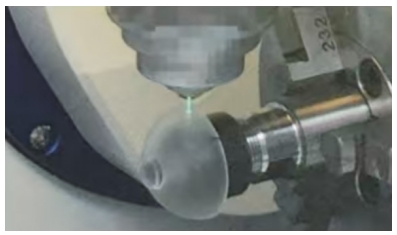

Self-developed aspherical surface measuring machine with dual contact and non-contact probes. The outer spherical roundness error, inner spherical roundness error and coaxiality error can be measured and obtained.

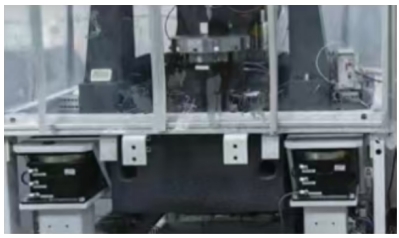

4. Plasma modification

PF6-250 plasma shaping machine tool can change the outer spherical roundness, inner spherical roundness, inner and outer spherical shell coaxiality and center column coaxiality. Resonator roundness change <100nm can be achieved within 15 minutes, and the roundness accuracy can be more than doubled.

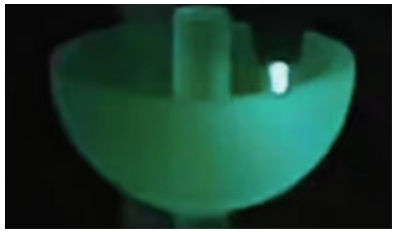

5. Measurement of laser vibrations

Self-developed HRM-2 integrated laser vibration measuring system can measure and obtain frequency difference, Q value and T value of hemispherical vibrator, obtain stiffness axis angle, determine leveling position of the mass and eliminate the mass.

6. Plasma quality leveling

PF6-250 atmospheric pressure plasma treatment equipment can measure vibration after treatment. It performs several iterative processes in collaboration with the HRM-2 vibration measurement system, achieving quality leveling with a frequency difference <1 MHz in a total time of 10 minutes.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.