GreatLight Precision: The Unseen Engine of Humanoid Robot Components

We understand the truth behind the motion—the relentless pursuit of perfection, the unseen precision, the silent endurance.

Just as every dedicated professional works tirelessly from dawn till dusk, our machines and our team operate with unwavering commitment. Day after day, part after part, we embody a simple truth:

True progress isn’t always loud—it’s built in layers of precision, repeated until perfect.

Why GreatLight?

Because we mirror the very qualities we build into your robotic components:

🔹 Relentless Consistency Like a machine running without pause, we deliver predictable, high-quality output—time after time, order after order.

🔹 Precision That Speaks in Silence The finest results often come without fanfare. Our five-axis CNC technology works quietly, accurately, and without compromise—just like the most dependable teammate.

🔹 Built to Endure We know the hardships behind seamless performance. That’s why we engineer every joint, frame, and actuator to last—to move, bear load, and perform under real-world demands.

🔹 Designed to Deliver In the end, it’s not about how busy we seem—it’s about the result. And our result is a component that fits, functions, and elevates the future of Humanoid Robot Components.

We Are the Motion Behind the Movement

From dynamic joint modules to lightweight exoskeletons—every part we craft carries not just technical specs, but the resolve to never fail expectations.

Let’s build the quiet kind of great—the kind that works, endures, and delivers, day in and day out.

#GreatLightPrecision #HumanoidRobotComponents #PrecisionEngineering #SilentExcellence #Reliability #RoboticsManufacturing #CNCMachining #BuiltToLast

Behind every seamless motion—is unseen, unwavering work. Contact us to build the durable, precise future of robotics—together.

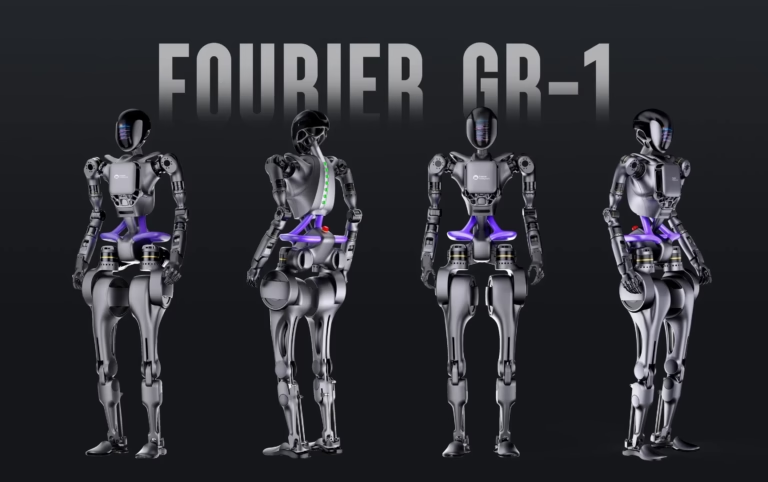

Introduction: Where Precision Engineering Meets Robotic Ambition

The creation of a humanoid robot—a machine that mimics the complex kinematics and dynamic balance of the human body—represents one of the most formidable challenges in modern engineering. While breakthroughs in artificial intelligence, sensor fusion, and control algorithms capture headlines, the physical embodiment of these capabilities hinges on a less celebrated but utterly critical discipline: the design and manufacture of precision CNC machined humanoid robot components. These are not mere brackets and covers; they are the skeleton, joints, and connective tissues of a synthetic being. The performance, reliability, and very feasibility of humanoids in environments from factory floors to disaster zones depend on components machined to exacting standards. This definitive guide explores the world of precision CNC machined humanoid robot components, examining the specific parts, their unique requirements, the advanced materials and processes used to create them, and the engineering rationale behind every design decision. For robotics engineers, procurement specialists, and innovators, understanding the intricacies of these components is the first step toward building a machine that doesn’t just move, but moves with strength, grace, and unprecedented reliability.

Part 1: The Unique Demands of Humanoid Robot Components

1.1 The Performance Trinity: Strength, Weight, and Precision

Humanoid robot components operate under a unique set of constraints that separate them from conventional industrial parts. Their design is governed by a relentless optimization of three competing factors:

- High Strength & Stiffness: Components must withstand significant dynamic loads—not just the robot’s weight, but also inertial forces from rapid acceleration, deceleration, and unexpected impacts. The structural frame, in particular, must have high stiffness to prevent unwanted flexure that would corrupt sensor data and destabilize the entire system.

- Minimal Mass: Every gram saved in a moving limb reduces the torque required from actuators, decreases energy consumption, and improves dynamic response. This makes the power-to-weight ratio of humanoid robot components a primary design driver. Lightweighting is not optional; it is fundamental to achieving human-like agility and viable battery life.

- Extreme Precision and Repeatability: The kinematic chain of a humanoid is exceptionally long, with error stacking from the foot to the hand. Bearing seats, gear meshes, and alignment features on humanoid robot components must be machined with micron-level accuracy to ensure smooth motion, minimize backlash, and guarantee that the robot’s physical geometry matches its digital twin. Poor precision leads to binding, wear, inefficiency, and control instability.

1.2 Environmental and Functional Challenges

Beyond basic mechanics, humanoid robot components must be engineered for their intended operational life:

- High-Cycle Fatigue Life: A humanoid joint may cycle millions of times over its lifespan. Components must be designed and manufactured to resist crack initiation and propagation under cyclic loading, a key consideration in material selection and machining strategy.

- Thermal Management: Actuators and drives generate heat. Components like actuator housings must often serve as heat sinks, requiring designs with high surface area and materials with good thermal conductivity. Machining must ensure perfect contact between components to facilitate heat transfer.

- Integration Complexity: A single humanoid robot component, such as a hip housing, is rarely just a structural piece. It is a multi-functional integrated assembly point that must precisely locate motors, bearings, sensors (absolute encoders, torque cells), and wiring harnesses. This demands sophisticated design with tight tolerances on interrelated features.

Part 2: Critical Component Categories and Their CNC Machining Specifications

2.1 Core Structural Skeleton: The Chassis and Links

The structural frame forms the robot’s backbone. These large, complex parts define the kinematic geometry and carry all other subsystems.

- Primary Components: Pelvis (hip) structure, chest/thorax cage, shoulder complexes, upper arm and forearm links, thigh (femur) and shin (tibia) links.

- Key Design & Machining Requirements:

- Topology-Optimized Designs: Often born from generative design software, these organic, skeletal shapes minimize mass while maximizing stiffness. Machining them requires advanced 5-axis CNC capabilities to handle complex, non-prismatic geometries.

- Internal Ribbing and Lightweighting Pockets: To achieve stiffness without mass, parts are machined with intricate internal networks of ribs and large, strategic pockets. This requires long-reach tools, careful toolpath planning to avoid chatter, and often, a sequence of operations from both sides of the workpiece.

- Perfectly Machined Mounting Interfaces: Every surface where another component attaches must be perfectly flat, parallel, or perpendicular, with precise hole patterns. These Datum features are critical for assembly accuracy.

- Material Choices:

- Aircraft-Grade Aluminum (7075-T6, 6061-T6): The most common choice for its excellent strength-to-weight ratio, machinability, and good thermal properties.

- Titanium Alloys (Ti-6Al-4V): Used for the highest-stress, most weight-critical components where aluminum’s strength is insufficient. Its machining requires specialized tooling and techniques due to low thermal conductivity and work-hardening tendencies.

- Precision CNC Machining Tolerances: Flatness and parallelism on critical faces: ≤ 0.02 mm. Hole positions for bearings: ±0.01 mm (true position). Surface finishes on sealing faces: Ra 0.8 μm or better.

2.2 The Joint Systems: Housings and Actuator Integration

Joints are the heart of motion. Their housings are among the most complex humanoid robot components to machine.

- Primary Components: Rotary actuator housings for hips, knees, ankles, shoulders, and elbows. Differential housing for advanced waist or wrist joints.

- Key Design & Machining Requirements:

- Bearing Bore Precision: The bores that house precision angular contact ball bearings or cross-roller bearings must be held to IT5 or IT6 tolerance grades (±0.005 mm or tighter). They require excellent roundness and cylindricity, often achieved through boring or precision grinding post-machining.

- Gearbox Integration: Many joints incorporate harmonic drive or planetary gear reducers. The housing must provide accurate, parallel mounting surfaces for the wave generator, flexspline, and circular spline, with zero backlash-inducing misalignment.

- Sealing and Lubrication Management: Complex internal galleries for grease channels and labyrinth grooves for seal integration must be machined flawlessly to ensure long-term reliability and exclude contaminants.

- Heat Sink Fin Integration: Actuator housings are often machined with intricate external fin arrays to passively dissipate heat from the motor and driver.

- Material Choices: 7075-T6 aluminum is standard. Magnesium alloys are an emerging choice for ultra-lightweight housings. Stainless steel (e.g., 17-4PH) may be used for high-wear internal sleeves.

- Precision CNC Machining Tolerances: Bearing bore diameter: H5/H6 fit. Bore concentricity between multiple bearing seats: < 0.01 mm. Gear mounting face squareness to bore axis: < 0.015 mm.

2.3 Specialized Load-Bearing Elements

- Output Flanges and Adapters: These components connect the joint’s output to the next limb segment. They experience high torsional and bending loads.

- Machining Focus: Accurate spline or bolt circle machining, and ensuring perfect perpendicularity between the mounting face and the central locating feature (dowel hole, pilot diameter).

- Torque Sensor Hubs: In robots with joint-level torque sensing, a specialized, slightly compliant hub is placed between the gearbox output and the limb. It is instrumented with strain gauges.

- Machining Focus: The flexure’s thickness must be machined with extreme consistency to ensure linear and repeatable strain response. This often requires micro-machining capabilities and superb surface finish to allow for proper strain gauge adhesion.

Table 1: Summary of Key Humanoid Robot Components & Machining Specs

| Component Category | Primary Function | Critical Machining Features | Typical Tolerances | Common Materials |

|---|---|---|---|---|

| Structural Link (e.g., Thigh) | Provides rigid connection between joints; carries loads. | Lightweight pockets, datum mounting faces, bearing seat prep. | Flatness: 0.02mm, Hole Position: ±0.01mm | 7075-T6 Al, 6061-T6 Al |

| Rotary Joint Housing | Encases actuator, bearings, gearing; provides structural loop. | Precision bearing bores, gear mounting faces, thermal fins, sealing grooves. | Bore Diameter: H5/H6, Concentricity: <0.01mm | 7075-T6 Al, Mg Alloys |

| Output Flange | Transmits torque from joint to limb. | Spline/bolt pattern, pilot diameter, mounting face. | Perpendicularity: <0.015mm | 7075-T6 Al, 4140 Steel |

| Torque Sensor Hub | Transmits load while providing measurable strain. | Precise flexure web thickness, gauge mounting surfaces. | Thickness Consistency: ±0.005mm | 7075-T6 Al, 17-4PH SS |

Part 3: The Precision CNC Machining Workflow for Robot Components

3.1 Design for Manufacturing (DFM) – The Collaborative Foundation

The journey of a humanoid robot component begins long before metal is cut. A collaborative DFM process between the robotics engineer and the machining specialist is crucial:

- Design Simplification: Can two parts be consolidated into one monolithic, stronger, and more precise component? CNC machining excels at complexity, reducing assembly error.

- Access and Tooling Consideration: Engineers must design internal features so that cutting tools can reach them. Minimum corner radii, cavity depths, and undercut accessibility are reviewed.

- Datum Strategy: A clear, logical datum scheme (primary, secondary, tertiary datums) is established on the CAD model. This dictates how the part will be held and measured, ensuring all features are machined in a coordinated system that mirrors the assembly intent.

- Stress Relief: Forging or pre-machining stress relief of raw material is planned to prevent distortion during and after machining.

3.2 Advanced Machining Techniques and Equipment

Producing humanoid robot components requires more than standard 3-axis mills.

- 5-Axis Simultaneous Machining: Essential for the complex contours of topology-optimized structures. It allows for finishing entire parts in one or two setups, eliminating cumulative error and enabling the machining of angled features and deep cavities with shorter, more rigid tools.

- High-Speed Machining (HSM): Using small step-overs at high spindle speeds and feed rates, HSM produces excellent surface finishes, maintains tight tolerances, and is ideal for machining thin walls and fine features in aluminum without inducing vibration.

- Multi-Pallet Machining Centers and Automation: For production runs, machines with automatic pallet changers allow for continuous, untended operation. A part is machined on one pallet while the operator sets up the next workpiece on another, maximizing machine utilization.

- In-Process Probing: Touch probes on the machine tool automatically measure the workpiece mid-process. This allows for automatic tool wear compensation, verification of critical features before proceeding, and adjustment of work coordinates, ensuring consistency across a production batch.

3.3 Post-Machining Processes and Final Integration

Machining is often followed by critical secondary operations:

- Heat Treatment: For steel components or to achieve specific tempers in aluminum (like T6 aging after machining solution-treated stock).

- Precision Grinding/Honing: Used to achieve the final, super-precise dimensions and surface finish on bearing bores and sealing surfaces beyond the capability of milling.

- Surface Treatments:

- Hard Anodizing (Type III): Applied to aluminum parts for extreme surface hardness and wear resistance on bearing surfaces and sliding contacts.

- Nickel-PTFE (Teflon) Coatings: Provide a low-friction, dry-lubricated surface for certain interfaces.

- Decorative Anodizing (Type II): For cosmetic external parts.

- Quality Assurance and Metrology: Every critical part undergoes final inspection on a Coordinate Measuring Machine (CMM) to generate a First Article Inspection Report (FAIR). This verifies the part against the 3D model, proving all humanoid robot components meet the digital design intent before integration.

Part 4: Material Science for Humanoid Applications

4.1 Aluminum Alloys: The Workhorse Material

- 7075-T6 Aluminum: The premium choice for high-stress humanoid robot components. Its tensile strength (over 500 MPa) approaches that of many steels, while its density remains that of aluminum. It is widely used for structural links, joint housings, and flanges. It is more challenging to machine than 6061 but offers superior performance.

- 6061-T6 Aluminum: Offers a better combination of machinability, weldability, and good strength. Often used for less critical structural members, brackets, and covers. Its lower cost and easier processing make it a common choice for prototypes and educational robots.

4.2 Advanced Materials for Extreme Performance

- Titanium (Ti-6Al-4V): The ultimate material for strength-to-weight and stiffness-to-weight ratios. Used in highly stressed, compact components like high-performance actuator housings or small, critical links. Its biocompatibility also makes it ideal for prosthetics and collaborative robots. The high machining cost is justified only where its properties are essential.

- Magnesium Alloys: Even lighter than aluminum, with good strength and excellent damping characteristics (vibration absorption). Gaining traction for large housing castings that are then finish-machined. Primary concerns are corrosion resistance and flammability during machining, requiring special safety protocols.

- Engineering Plastics (PEEK, UHMW-PE, Delrin): Used for low-friction, self-lubricating bushings, lightweight gears (in lower-load applications), and insulating components. They can be precision CNC machined to create complex, low-wear parts.

Part 5: The Supplier Partnership – More Than a Machine Shop

5.1 Selecting a Partner for Humanoid Robot Components

Choosing a manufacturer for humanoid robot components requires evaluating specific competencies:

- Technical Expertise in Robotics: Look for a supplier with a portfolio in aerospace, medical devices, or competitive robotics. They understand the language of precision, lightweighting, and reliability.

- Full-Service Capability: The ideal partner can handle the entire value chain: collaborative DFM, precision 5-axis machining, heat treatment coordination, finishing, and comprehensive inspection. This single-point accountability is invaluable.

- Prototyping-to-Production Scalability: They should be adept at rapid, flexible prototyping to support your R&D, with a clear, quality-controlled pathway to scale up for pilot production and volume manufacturing.

- Quality System Credentials: Certifications like AS9100 (aerospace) or ISO 13485 (medical) are strong indicators of a culture suited to the demands of critical humanoid robot components.

5.2 The Economics of Precision: Cost vs. Value

While precision CNC machined humanoid robot components have a higher upfront cost than cast or fabricated alternatives, they deliver superior value:

- Performance Value: Enables higher robot speed, longer battery life, and greater payload capacity.

- Reliability Value: Reduces downtime from wear, misalignment, or failure.

- Development Speed Value: Allows for rapid design iterations with predictable, high-quality parts, accelerating the overall R&D timeline.

- System-Level Savings: A precisely machined component often simplifies assembly, reduces the need for shimming and adjustment, and improves the performance of all the expensive subsystems (actuators, sensors) attached to it.

Conclusion: Engineering the Physical Intelligence

The dream of capable, reliable humanoid robots is built, quite literally, on the foundation of precision CNC machined humanoid robot components. These parts translate digital control signals into graceful, powerful, and purposeful physical motion. As humanoid robotics progresses from labs to real-world applications, the demand for even more advanced components—lighter, stronger, more integrated, and more intelligent—will only grow. The collaboration between visionary roboticists and master machinists, grounded in the principles of precision engineering and materials science, will continue to push the boundaries of what is physically possible. In this synergy lies the key to unlocking a new generation of robots that can work alongside us, assist us, and explore realms beyond our own.