Introduction to IATF 16949 Certification

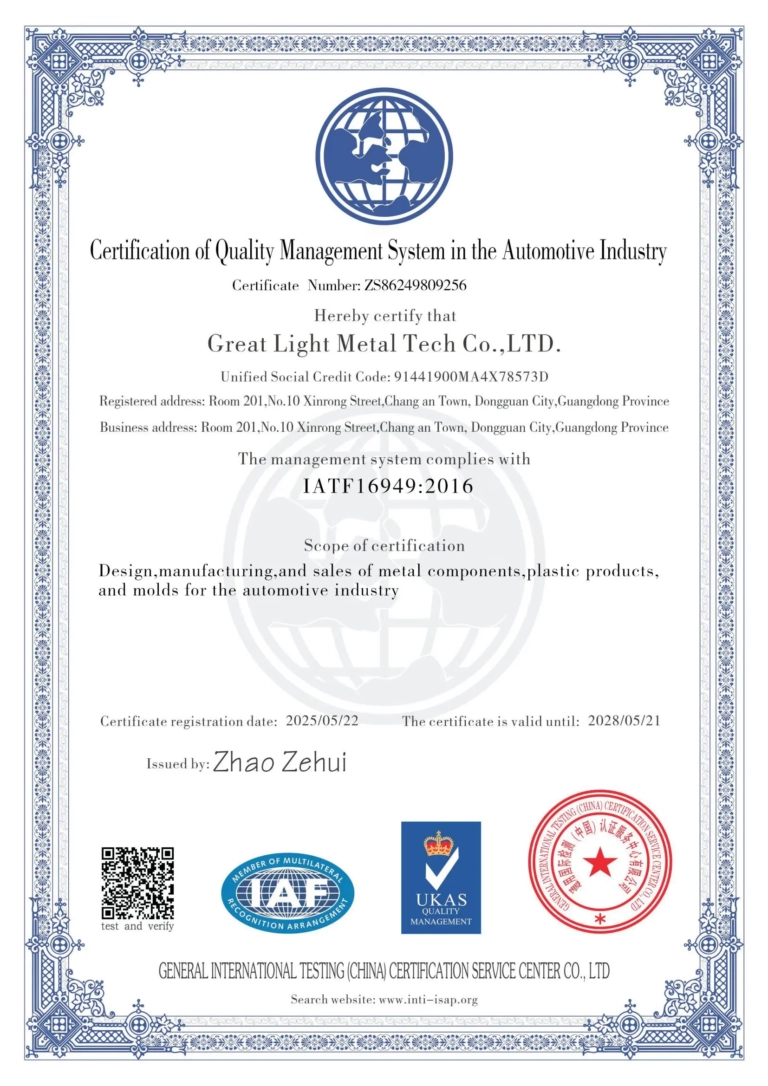

In the competitive world of automotive manufacturing, achieving IATF 16949 Certified status is a milestone that underscores a company’s commitment to exceptional quality and process excellence. GreatLight Metal’s recent attainment of the IATF 16949 Certified designation signals to US auto giants—and the entire supply chain—that our 5 Axis CNC machining processes consistently meet the rigorous automotive industry requirements.

Understanding IATF 16949 and Its Significance

What Is IATF 16949?

IATF 16949 is the international quality management standard specifically designed for the automotive sector. It integrates ISO 9001 requirements with supplemental automotive-specific criteria, focusing on defect prevention, process variation reduction, and continuous improvement.

Core Elements of the Standard

- Process Approach: Emphasizes uniformity and efficiency across design, production, and servicing.

- Risk-Based Thinking: Prioritizes proactive identification and mitigation of potential quality issues.

- Continual Improvement: Drives systematic enhancements in both manufacturing and quality management systems.

How GreatLight Metal Achieved IATF 16949 Certified Status

Comprehensive Quality Management System

GreatLight Metal overhauled its quality management framework to align with IATF 16949 requirements. Key initiatives included:

- Documented control plans for every CNC machining operation.

- Detailed failure mode and effects analysis (FMEA) for critical processes.

- Rigorous supplier quality assessment and approved vendor lists.

Advanced Process Control and Validation

To secure IATF 16949 Certified recognition, our team implemented:

- Inline statistical process control (SPC) on dimensional tolerances and surface finishes.

- Automated tool monitoring and breakage detection on 5 Axis centers.

- Regular calibration schedules for all inspection equipment (CMMs, laser scanners).

Benefits of IATF 16949 Certification for US Auto Giants

Assurance of Consistent Quality

For major OEMs, partnering with an IATF 16949 Certified supplier like GreatLight Metal means:

- Minimization of part-to-part variability.

- Reduced risk of field failures and costly recalls.

- Seamless integration into global automotive quality management systems.

Accelerated Time-to-Market

Adherence to standardized processes and documentation enables faster design-to-production cycles, so US auto giants can:

- Rapidly prototype and validate new components.

- Scale production without compromising on quality.

Customer-Centric Advantages of IATF 16949 Certification

Enhanced Traceability

Every batch of machined parts comes with complete digital records—material certificates, SPC charts, and inspection reports—allowing end users to trace each component back to its origin.

Lower Total Cost of Ownership

By reducing defects and rework, our IATF 16949 Certified processes drive down scrap rates and warranty claims, translating into significant savings over the lifecycle of the vehicle.

Streamlined Communication

Standardized documentation formats (PPAP packages, IMDS data sheets) simplify customer audits and conform to OEM and tier-one requirements.

Why Choose GreatLight Metal as Your IATF 16949 Partner

State-of-the-Art 5 Axis CNC Equipment

From high-speed aluminum pocketing to complex stainless steel aerospace components, our machining centers deliver sub-0.005″ accuracy and repeatability.

End-to-End Production Expertise

Our turnkey capabilities encompass:

- Custom Fixture Design: Optimized for each unique part geometry.

- Advanced Finishing: Anodizing, passivation, bead blasting, and laser etching.

- Assembly & Testing: Complete mechanical or hydraulic testing to validated specifications.

Global Reach with Local Support

As an IATF 16949 Certified supplier, we’re qualified to serve leading automotive OEMs in North America, Europe, and Asia—backed by dedicated project managers and technical liaisons.

Conclusion

GreatLight Metal’s achievement of IATF 16949 Certified status is more than a badge—it’s a testament to our unwavering dedication to quality, process rigor, and customer success. US auto giants now have a trusted partner capable of delivering high-precision, automotive-grade components with complete traceability and cost-effective performance. Choose GreatLight Metal for your next 5 Axis CNC machining project and experience the clear advantages of working with a certified industry leader.