The Evolution of CNC Technology: A Comprehensive Guide

The world of computer numerical control (CNC) has undergone significant transformations since its invention in the 1950s. From its humble beginnings as a simple numerical control system to the sophisticated, high-tech solutions we see today, CNC technology has revolutionized the manufacturing industry. In this comprehensive guide, we’ll delve into the world of CNC, exploring its history, key components, classification, and trends.

History of CNC

CNC technology was first introduced in the 1950s, with the first CNC machine, the XX-101, developed by the University of Cincinnati. The first commercial CNC machine, the Distributed Numerical Control (DNC), was launched in the 1960s. Since then, CNC technology has continued to evolve, driven by advances in computer processing power, memory, and networking.

Key Components of CNC Machines

A CNC machine consists of three primary components:

- Host: The host is the brain of the CNC machine, responsible for processing data and sending instructions to the machine. It’s often a computerized device with a graphical user interface (GUI) for program creation and editing.

- Drive device: The drive device, also known as the actuator, is responsible for moving the machine’s tool or workpiece. It can be an electric, hydraulic, or pneumatic system, depending on the specific application.

- Auxiliary devices: These devices support the CNC machine by providing additional functionality, such as coordinated controls, interpolation, and compensation. They can include accessories like cooling systems, lubrication, and protection.

Classification of CNC Machines

CNC machines can be classified in various ways, including:

- By Control System:

- Open-loop control systems, which use predefined coordinates and lack feedback control.

- Closed-loop control systems, which use feedback signals to adjust movement and improve precision.

- Semi-closed loop control systems, which combine elements of both open- and closed-loop systems.

- By Type of CNC Device:

- Software-based CNC devices, which use microprocessor-controlled systems.

- Hybrid CNC devices, which combine software and hardware components.

- By Treatment Method:

- CNC cutting machines, such as milling, drilling, and turning machines.

- CNC flame cutting machines, used for cutting and shaping materials like metal and wood.

Trends in CNC Technology

Modern CNC technology is characterized by rapid advances in computing power, memory, and networking capabilities. Some of the key trends influencing the industry include:

- Artificial Intelligence (AI) Integration: The increasing adoption of AI in CNC systems is enabling real-time adjustment and optimization of machine performance and material processing.

- Cloud Computing: Cloud-based CNC systems are offering greater flexibility, scalability, and collaboration capabilities for manufacturing organizations.

- 5G and IoT Integration: The integration of 5G networks and IoT sensors is expected to further enhance machine-to-machine communication and data exchange in CNC systems.

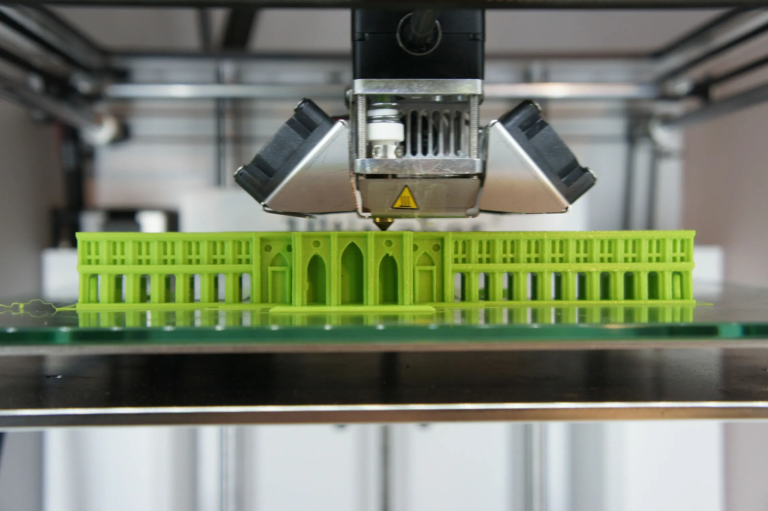

- Additive Manufacturing: The growing popularity of 3D printing and additive manufacturing is driving demand for advanced CNC systems that can handle complex geometries and materials.

- Cybersecurity: As CNC systems become more connected and dependent on the cloud, cybersecurity measures are becoming increasingly important to protect against threats and data breaches.

Conclusion

In this comprehensive guide, we’ve explored the history, key components, classification, and trends in CNC technology. From its humble beginnings to the sophisticated solutions we see today, CNC has revolutionized the manufacturing industry. As the technology continues to evolve, it’s essential to stay ahead of the curve, embracing innovations like AI, cloud computing, and IoT integration. By doing so, manufacturers can ensure optimal performance, efficiency, and competitiveness in the global market.