![]() Three new products unveiled on the same stage

Three new products unveiled on the same stage

01 SLM industrial grade 3D printing equipment: from Muees310 to Muees430

Last year, Luentech introduced SLM Muees310 metal 3D printing equipment to everyone at Formnext+PM 2023, South China. This year, Luentech Technology launched another masterpiece for this series of equipment – Muees430, and made a grand appearance at Formnext+PM South China 2024:

Features of Muees series products

1. Optical system:

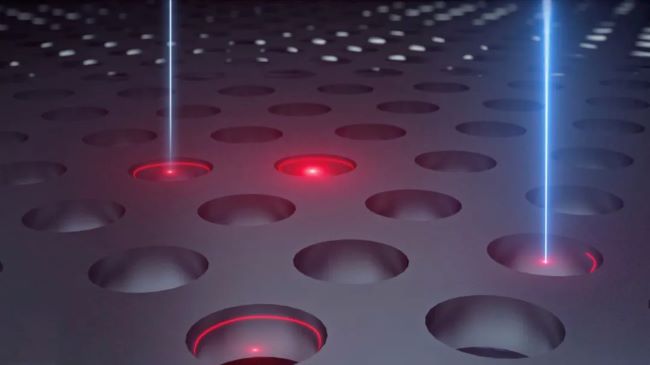

① Adopts multi-laser optical path design and supports multi-galvanometer configuration, which can improve the overall casting efficiency

② Equipped with imported 500W high-power laser. After long-term continuous testing, the power fluctuation is stable within ±1%; On the focusing plane, the beam quality reaches M²≤1.2, the energy distribution is more uniform, and the printing quality is more delicate.

③ Equipped with high-speed galvanometer, the scanning speed can reach 6m/s and the jumping speed can reach 18m/s, which can achieve efficient printing at the same time, the galvanometer has low drift and stronger stability.

④ Built-in large-format field lens, custom development, full-frame spot uniformity of up to 92%, achieving consistent wall thickness and significantly improving printing precision

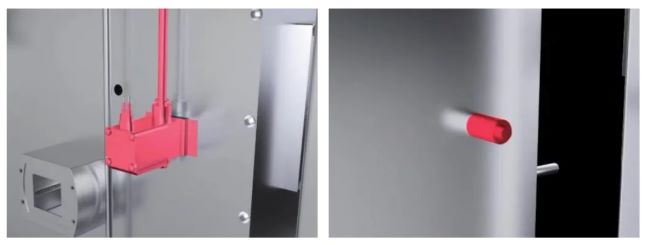

2. Automatic calibration:

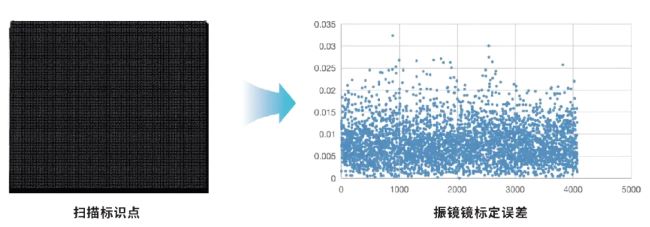

Since the scanning imaging principle of the galvanometer will cause some distortion of the graphs, in order to ensure dimensional accuracy, the scanned graphs must be corrected. Luentech has independently developed automatic galvanometer calibration and multi-galvanometer splicing calibration technology based on image processing. Using image detection technology, the distortion of the galvanometer is corrected. After calibration, the optical scan size accuracy is <0.05mm and the calibration time is less than 30 minutes; the maximum calibration error can be 0.032mm and the percentage of points with deviation. <0.032mm represents 99.9%. This technology guarantees the dimensional accuracy of a single galvanometer, and also has a great advantage for the dimensional accuracy of automatic splicing of multiple galvanometers.

3. Electronic control system:

① Safe and stable:

The safety circuit is designed in accordance with the 13849 safety specification standards, and the safety level of the equipment is greatly improved; multi-sensor units are integrated internally and the equipment is intelligently upgraded to enable protection upgrade;

②High precision:

The forming cylinder movement axis is equipped with a high-precision magnetic scale, which can achieve full closed-loop control and more precise overlay which ensures stable printing;

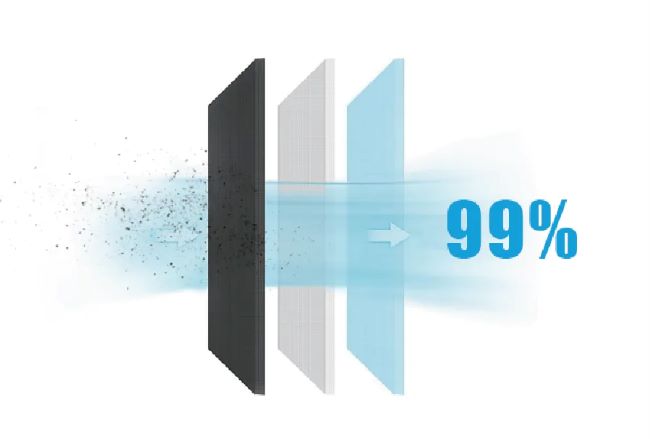

4. Atmospheric circulation system:

Multi-stage high-efficiency filtration can achieve more than 99% cleanliness of inert gas; high pressure backwashing improves the life of the filter element, which can reach 10,000 hours.

5. Equipment structure:

① Single-blade two-way powder spreading structure can reduce auxiliary production time and improve processing efficiency

③ Equipped with high-precision imported spline shafts and precision screws to ensure stable transmission of the forming shaft during high-load movement; Fully enclosed design scraper drive shaft, dustproof effect;

Better and can extend the life of the drive shaft; Large capacity aggregate bucket (powder overflow tank) can reduce the number of powder cleaning times.

6. Wind farm:

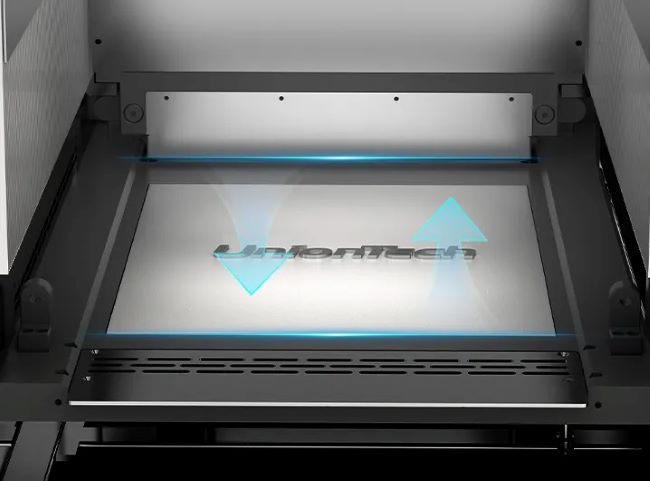

① Real-time wind speed detection, constant wind speed control

② By combining wind field airflow simulation with experimental testing to optimize the air path structure, the wind field flow in the molding room is smoother and more uniform.

02 Fully automatic 3D printing equipment DLP: D300 a whole new definition of automated dental production

02 Fully automatic 3D printing equipment DLP: D300 a whole new definition of automated dental production

Luentech, as one of the first domestic enterprises to enter the field of additive manufacturing, established a surface exposure technology R&D team as early as 2013 and conducted in-depth exploration. Today, its DLP surface exposure equipment fully meets the diversified applications in various fields such as dental, animation, shoe industry, education, industry, jewelry and medical care .

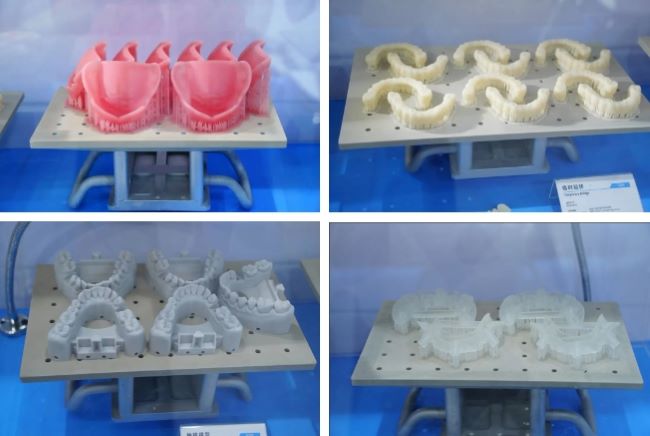

To further unlock a new level of intelligent production, Luentech has launched a new fully automated DLP dental 3D printer, the D300. It features two built-in top projection 4K light engines, with a casting size of 258 x 230 x 120mm. Compared with the precision of D800, which has a deviation of less than 0.07mm, D300 can achieve high precision molding of 0.05mm. And this equipment is mainly for large and medium-sized denture processing factories. It is applied to the two main models of restoration and layout and realizes the entire 3D printing process from automatic plate division, automatic queuing, automatic filling to printing automatic, automatic unloading, sorting assistance, etc. Automated production makes “7×24 unattended” possible.

03 Professional-grade LCD 3D printing equipment: Matrix family adds new member Matrix300

As the flagship product of Luen Thai Technology, the Matrix series adds a new member, Matrix300, in addition to Matrix190 and Matrix520. The device adopts a 10-inch 12K screen design. Compared with the common square resolution on the market, the overall value is improved to 19 × 24 μ. And it is specially equipped with COB light source, which is simplified into a single lamp without grid lines, the printing uniformity can reach more than 90%, and the light intensity is more powerful than dot matrix light. source. At the same time, Matrix300 has achieved another advancement in printing speed. High-speed materials can be printed stably at 130mm/h, and ordinary materials can be printed at 60-70mm/h. same series.

![]() Unblock multiple apps with just one click

Unblock multiple apps with just one click

01 Industrial application

02 Automotive applications

03 Tire application

04 Cultural and creative applications

*Some exhibits are derived from cyanobacteria technology

05 Application to the shoe industry

06 Oral request

07 Medical applications

![]() Professional collision at the top of the industry

Professional collision at the top of the industry

New Energy Vehicle Additive Manufacturing Applications Summit

Mr. Zeng Ang, BD Director of Luentech Technology, attended the New Energy Vehicle Additive Manufacturing Application Summit and gave a wonderful sharing to the audience on the construction and breakthrough of 3D printing solutions at the industry. He said that 3D printing technology can alleviate quantitative constraints, structural constraints and production capacity constraints in production and manufacturing, and implement environmental protection and double carbon concepts under form of digitalization and automation. This advantage has enabled 3D printing technology to achieve diversified applications in automotive industry segments such as prototypes and functional verification, terminal part production, tooling fixtures, and tire molds. . Further developments in additive manufacturing will also break the initial inertia of large-scale thinking, both at the design and manufacturing levels, to deepen cognitive coherence and cooperation across supply chains upstream and downstream.

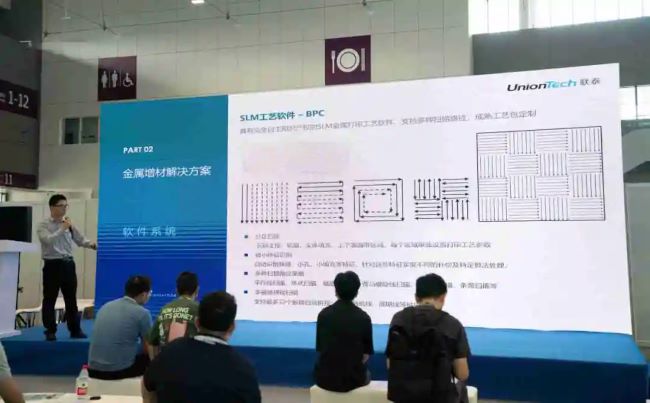

Shenzhen International Additive Manufacturing, Powder Metallurgy and Advanced Ceramics Exhibition, New Product Launch Conference

Mr. Wang Zhoutai, Sales Manager of Luentech Footwear Division, attended the new product launch conference of Shenzhen International Additive Manufacturing, Powder Metallurgy and Advanced Ceramics Exhibition, and introduced to the audience Luentech’s industrial grade metal additive system solutions. He gave simple and in-depth explanations on several major dimensions such as intelligent software systems, Muees series metal forming equipment, powder management systems and typical applications of metal 3D printing. While highlighting the overall technical strength of Luentech technology, it has further strengthened the functionality. Guests’ understanding of metal 3D printing. He said that in the future, Luen Thai Technology will focus on investing more energy in efficiency, consistency, equipment stability, usage automation, partial intelligence, etc. of metal forming, and will promote the innovative development of the entire industry through technological research and development. .

Luentech Metal 3D Printing Application Case

![]() On-site interaction is full of fun

On-site interaction is full of fun

At this exhibition, experts from various business divisions of Luentech Technology conducted in-depth discussions with guests from multiple dimensions such as equipment, materials, applications and software:

Create without borders and create the future! The deep integration of additive manufacturing technology into various industries is a concrete product of technological development and the general trend of changing times. In the future, Luentech will continue to increase investment in R&D and use the spirit of innovation to help the development of additive manufacturing technology flourish!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.