Rapid prototyping manufacturing technology has developed rapidly over the years. with 3D With the development of printing technology, the materials used are also constantly evolving. At first, printing materials were scarce, but with research and development, the number and variety of materials gradually increased. The best known are of course polymers (PLA、ABSresin, nylon) and metal. But today we want to specifically highlight two categories of materials: ceramic materials (which include many hard inorganic materials like ceramics, but also sand or cement) and organic materials.

ceramic material

ceramic

When we think of ceramics, we usually think of traditional ceramics like clay or porcelain. But there are also technical ceramics for advanced applications. There are currently two main categories of technical ceramics on the market: oxides and non-oxides. The first category includes metal oxides such as alumina, zirconia and silicon dioxide, while the second category includes materials such as silicon carbide, silicon boride and silicon nitride. These materials are ideal for components that must withstand high temperatures and wear, such as ceramic components needed in the automotive and aerospace industries. ceramic 3D Printers can use different manufacturing processes: powder bonding, stereolithography, extrusion or photopolymerization.

sand

Sand can be considered a ceramic material. It makes it possible to manufacture complex parts, taking advantage of the advantages of additive manufacturing, particularly for the production of casting molds. The use of this material reduces waste and production times are much shorter than other technologies. It can be used for mass production of finished products as well as for prototyping, e.g. ExOne of S-Max Flex machine. In the video below you can see The real hero to use 3D An example of sand printing technology making more durable bathroom accessories.

cement

Cement is another ceramic material that we want to highlight. During production, stone particles and water are mixed to form a uniform paste, which can also be used 3D Print. As a result, additive manufacturing is becoming increasingly important in the construction sector. Using concrete as a building material is very cheap and the printers cost between 18 million euros to 100 Ranging from several tens of thousands of euros. Concrete 3D printers available on the market include House Apis Cor printer and WASP of Crane printer. One of the advantages of these machines is their speed:48 You can build the walls of a house in just an hour!

wood and stone

These ceramic materials are mainly used in filamentary form FDM/FFF 3D molding machine. There are also solutions like Metal desk to use Forest™ Technology material jet 3D printer, which can be used for 3D printing of wood materials. As for the filaments, they contain 30-40% wood fiber and 60-70% polymers; even the stone filaments are made from a mixture of plaster and plastic. Manufacturers offering both filament types include ColorFabb And Shaping the future. The amazing thing about these materials is that they really resemble wood and stone and can be used to create more durable finished pieces.

organic materials

organic tissue

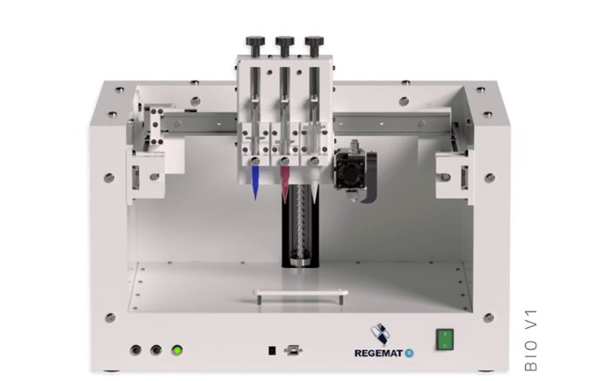

Having understood ceramic materials, we now turn our attention to organic materials, particularly materials used for three-dimensional bioprinting. The process involves using ink made up of cells that can be used to create skin, tissue, tendons and even organs. Printing usually involves the sequential deposition of several layers using a special syringe. There are more and more latest discoveries and innovations in this field, and the prospects are getting brighter and brighter! For more information, check out our article on the latest and greatest 3D Articles on bioprinting projects.

wax

This organic material is primarily used for shaping in many fields and applications, including mechanics, art, dentistry and jewelry. In terms of hardware,3D systems of MJP 3600W Project And 3600 W maximum Using a 3D molding machine M3 Hi-Cast Material.Prodways belonging to Solid landscape The company also specializes in the production of 3D wax printers, offering a full range of machines specifically designed for the jewelry industry.

food

who would have thought 3D Can the printer be used to print food? Barilla (Barilla)to use 3D spaghetti has been printed, other companies are printing chocolate, and we saw it again recently 3D Print the progress of meat and fish. This technology is revolutionizing cooking! The question is: is there a food printer? The answer is yes. These printers include Natural machines of Foodini、Brill 3D Culinary Studio、Mycuisini 2.0 or for chocolate printing Shock Creator V2 Plus. We bring them together in the best foods 3D Printer ranking.

source:.3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.