1

Pin Definition

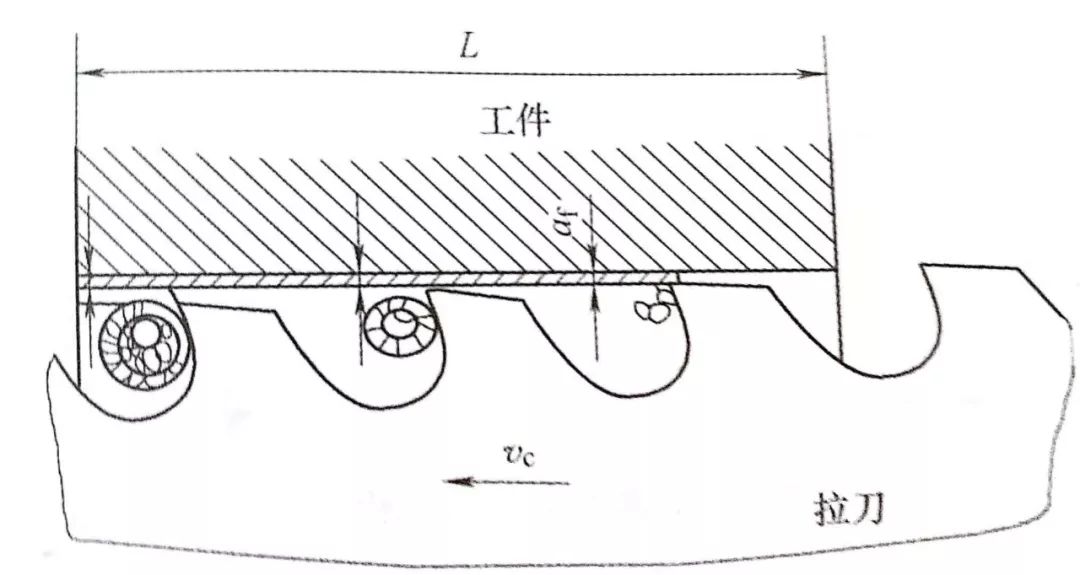

The spindle is a multi-tooth tool with high production efficiency and high precision. When broaching, the spindle moves in a straight line at a constant speed, which is the main movement. Since the last tooth (or group) of the spindle is taller than the previous tooth (or group), it can sequentially cut layers of metal from the workpiece to achieve the desired surface area. When broaching, the feed movement is replaced by the lifting of the cutter teeth, so there is no feed movement when broaching. There are many types of pins, generally divided into two categories: inner pin and outer pin.

2

Pin Classification

Different treatment surfaces

Internal broaching tools are used to process interior surfaces of various shapes. The name of the broaching tool is usually determined by the shape of the hole to be processed, such as round hole broaching, four/six square broaching, keyway broaching and spline broaching. . wait. Internal spindles can also process internal spiral splines and internal gears. The hole diameter that can be processed by the internal broaching tool is generally 10-120mm, and it can be processed up to 5-400mm under special circumstances. The groove width for broaching is generally 3 to 100 mm. exceed 3 times the diameter. Under special circumstances, it can be processed up to 2 m. The most common include round hole broaches, spline broaches, square hole broaches, and keyway broaches.

External broaching tools are used to process various shapes of external surfaces, such as planar surfaces, forming surfaces, grooves, complex grooves, mortises and tenons in steam turbines, to replace milling, planing, grinding and other processing of these parts. particularly suitable for surfaces of certain parts in mass production of cars, motorcycles, tractors, etc. In production, internal broaching tools are more commonly used than external broaching tools.

Different directions of force

It can be divided into skewer knife and push knife. The first is under tension and the second under pressure. Considering the stability of the pushing rod, the length/diameter ratio of the pushing tool should be less than 12.

Pin structures are different

It can be divided into combined type, integral type and assembled type.

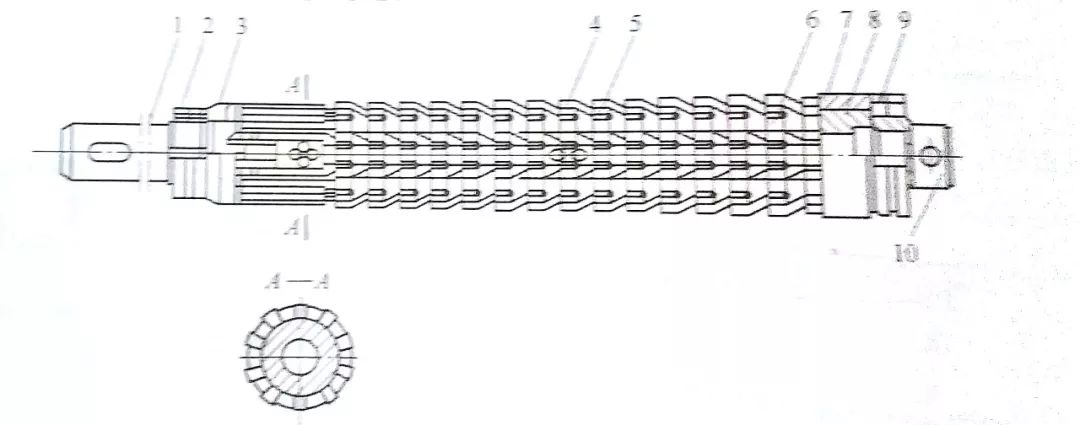

1 Combination Spindle: Using a combination spindle can not only save tool materials, but also simplify the manufacturing of the spindle and can be easily adjusted or replaced when the spindle teeth are worn or damaged. Below picture of the combination spline pin.

1 cutting body round nut 2/9 3 pressure ring 4 pressure block screw 5/7

6 blade 8 retaining ring 10 tail

2 Integral spindle: The integral type mainly uses small and medium-sized high-speed steel integral spindles.

3. Prefabricated Broaches: Prefabricated broaches are mainly used for carbide dimensional and combination broaches.

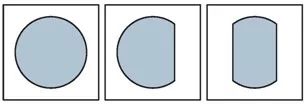

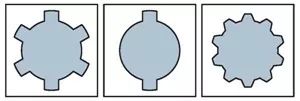

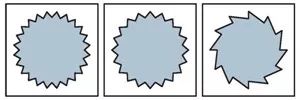

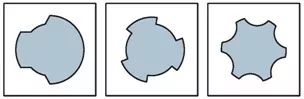

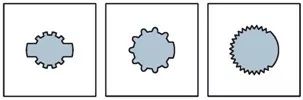

Broaching tools can be used to process through holes of various cross-section shapes, straight lines or curved outer surfaces. The following shows you the classic cross-section shape of the workpiece for broaching.

Round pins

Splined pins

Fine tooth pins

Polygonal brooch

Special shape pins 1

Special shape pins 2

3

Pin specifications

The broaching process is carried out with a pin. It is based on the fact that the last tooth (or group) of the spindle is higher than the previous tooth (or group), and the extra thickness is cut off layer by layer to obtain the required value. quantity. When broaching, the spindle moves in a straight line at a constant speed. Since the last tooth (or group) of the pin is taller than the previous tooth (or group), excess metal can be cut from the part layer by layer.

Due to the low broaching speed and low cutting thickness, higher precision and better surface quality can be achieved. Compared to other transformation methods, pinout has the following characteristics:

1 The structure of the broaching machine is simple: broaching generally has only one main movement (the linear movement of the spindle), and the feeding movement is supplemented by the lifting of the spindle teeth. Therefore, the broaching machine has a simple structure and is easy to operate.

2. High machining precision and surface quality: Generally, broaching machines use hydraulic system with smooth transmission; the broaching speed is low, generally 0.04-0.2m/s (2.5-12m/min), which is not prone to accumulation. The cutting edge and thickness are very low. Generally, the cutting thickness of precision cutting teeth is 0.005-0.015mm, because the processing precision can reach IT7, and the surface roughness value is Ra0.8-2.5μm.

3. High production efficiency: Since the broach is a multi-tooth tool, many teeth participate in the work at the same time, the overall cutting edge length is large, and roughing, semi-finishing and finishing can be completed. all at once, so the production efficiency is very high.

4. The spindle has a long service life: due to the low cutting speed and slow wear of the broaching, the spindle has high durability. At the same time, after the spindle teeth are ground, they can be resharpened many times and have a long service life. life.

Since the structure of the pin is more complex than that of ordinary tools and its manufacturing cost is high, it is generally used in mass or batch production. However, exceptions are made for those with higher precision requirements and special shapes.

4

The structure of the pin

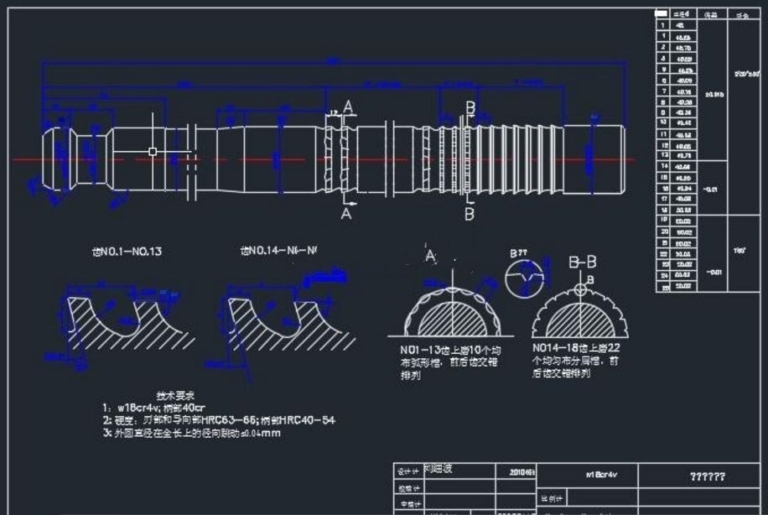

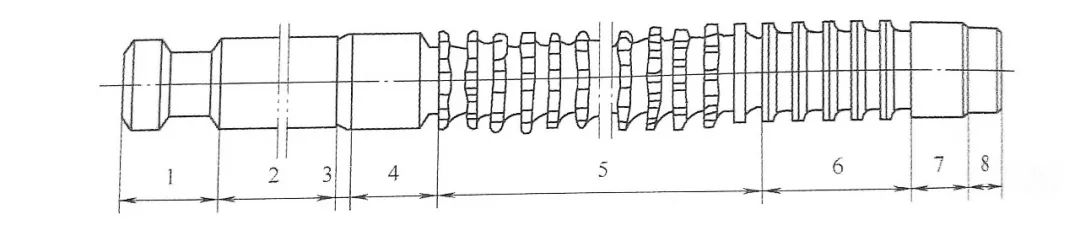

The structure of the round hole pin is shown in the figure:

1 Head 2 Neck 3 Transition cone part 4 Front part

5 cutting part 6 calibration part 7 rear part 8 tail

1 head – connected to the machine tool, transmitting movement and tension.

2. The neck, the connecting part between the head and the excessive taper, is also the place to be marked.

3. Transition taper part – plays a guiding role, allowing the pin to easily enter the prefabricated hole in the workpiece.

4 Main Section – Guides the spindle to move to the cutting section smoothly and without bias.

5. Cutting part responsible for removing all machining allowances. It consists of primary cutting teeth, transition teeth and finishing teeth.

6. Calibration part – the latest teeth without tooth lifting and chip separation groove play the role of polishing and calibration to improve the machining precision and surface quality of the hole, and can be used as teeth rear precision cutting teeth.

7. Rear guide part – used to maintain the correct position of the last teeth of the spindle, to prevent the spindle from sagging when it is about to leave the workpiece and damage the quality of the processed surface and the teeth.

8 Tail – When the spindle is long and heavy, you can use a stand to support the shank of the drill bit to prevent the spindle from sagging due to its own weight. Generally, lighter pins do not need a tail.

5

Pin case sharing

01Inner hole pin

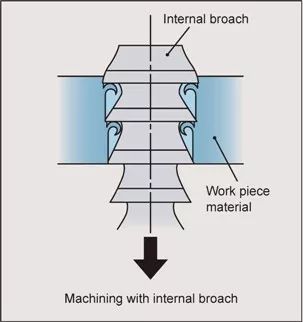

Internal broaching tools can effectively form a specific shape on the inner surface of the workpiece with high precision.

Typically, an internal pin is inserted into a pilot hole formed in the part before machining.

Different types of holes can be formed by selecting the best cutting edge shape and cutting method (such as round holes, square holes, polygonal holes and various spline holes and tapered holes).

Internal Hole Pin Case

02Surface pin

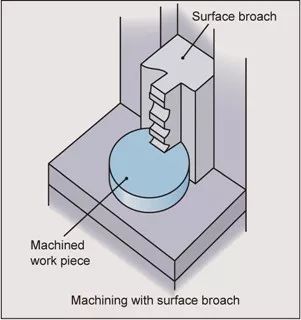

Surface broaches can create specific shapes on the outer surface of parts efficiently and with high precision.

Roughing and finishing can be carried out simultaneously, which means productivity is significantly higher than milling, finishing and grinding.

It can process a variety of shapes (such as planar surfaces, contour surfaces, various concave and convex surfaces, gears, turbine blade roots, turbine disk grooves), and its contour can be either a simple shape like a keyway, or a complex shape like a fir tree.

Noodle pin case

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.