The Critical Role of Five-Axis CNC Machining in Precision Part Manufacturing

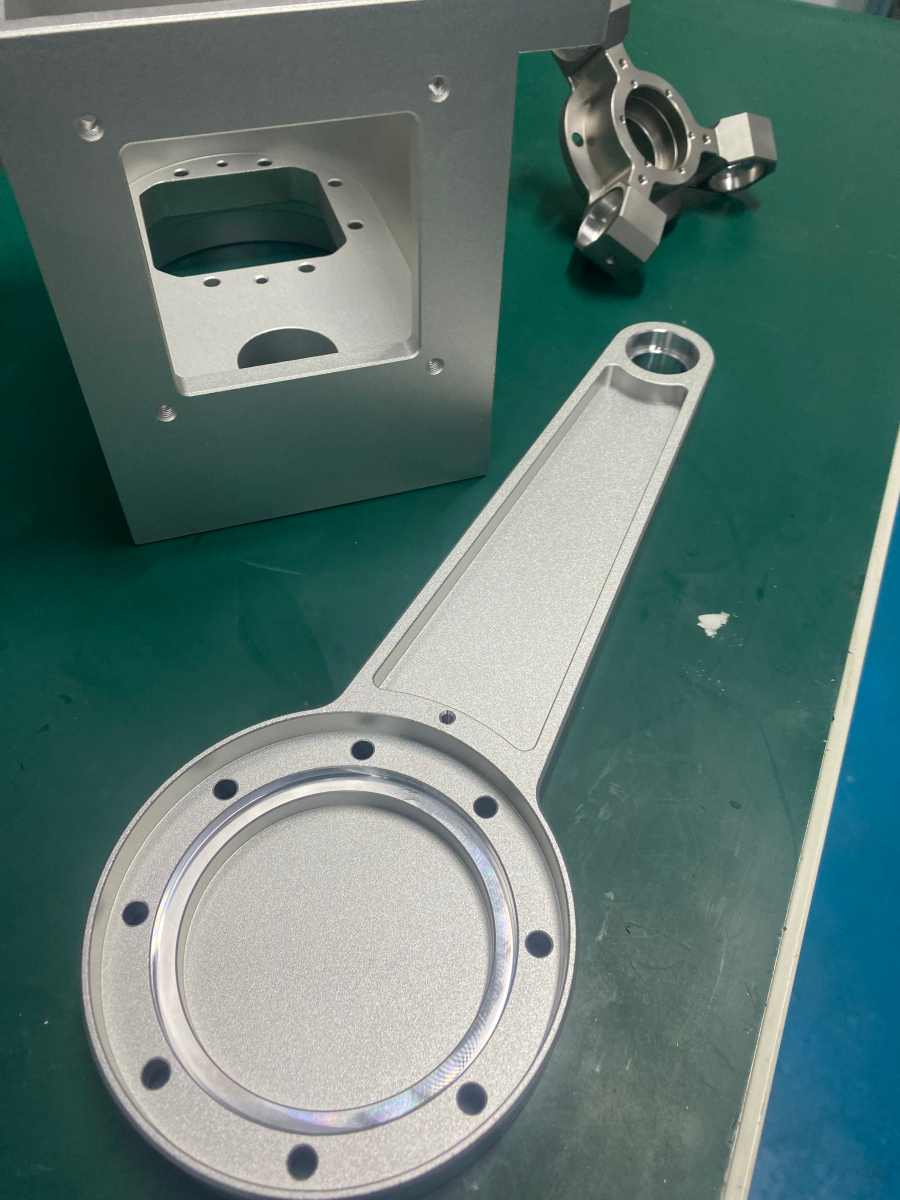

In the realm of high-end equipment development, the transition from conceptual design to mass-produced precision parts remains a formidable challenge. While 3D printing excels at rapid prototyping, CNC machining stands as the cornerstone for producing functional components with unparalleled accuracy, surface finish, and material versatility. Among CNC technologies, five-axis machining has emerged as a game-changer, enabling the fabrication of complex geometries that traditional three-axis systems cannot achieve. For R&D teams, hardware startups, and engineering managers, selecting a supplier capable of delivering ±0.001mm tolerance parts with full-process chain integration is not just a technical decision—it’s a strategic imperative.

Why Five-Axis CNC Machining? The Technical Edge Over Conventional Methods

1. Unlocking Complex Geometries

Five-axis CNC machines operate on three linear axes (X, Y, Z) and two rotational axes (A, B), allowing the cutting tool to approach the workpiece from any angle. This capability eliminates the need for multiple setups, reducing human error and ensuring consistent dimensional accuracy across intricate features like undercuts, deep cavities, and compound curves.

Example: A humanoid robot joint with helical gears and curved housing requires simultaneous machining of multiple surfaces. A five-axis system completes this in one clamping, whereas a three-axis machine would demand repositioning, risking misalignment.

2. Superior Surface Finish and Material Efficiency

By optimizing tool orientation dynamically, five-axis machining minimizes vibration and tool wear, yielding Ra 0.4–0.8μm finishes without secondary polishing. It also reduces material waste by enabling near-net-shape cutting, critical for expensive alloys like titanium or Inconel.

| Comparison: | Metric | Five-Axis CNC | Three-Axis CNC |

|---|---|---|---|

| Setup Time | 1–2 hours (single setup) | 4–6 hours (multiple setups) | |

| Surface Roughness (Ra) | ≤0.8μm | ≥1.6μm | |

| Material Utilization Rate | 85–90% | 60–70% |

3. Scalability from Prototyping to Production

Unlike 3D printing, which struggles with anisotropic properties (weakness in layered directions), five-axis CNC produces isotropic parts with uniform strength, making it ideal for functional testing and end-use applications. Suppliers like GreatLight CNC Machining Factory leverage this to offer seamless transitions from low-volume prototypes to high-volume production runs.

The Precision Predicament: Seven Common Challenges in CNC Machining

Despite its advantages, CNC machining is fraught with pitfalls that can derail projects. Below are critical pain points—and how GreatLight Metal addresses them:

1. The “Precision Black Hole”: Overpromised Tolerances, Underdelivered Results

Many suppliers claim ±0.001mm accuracy but fail to sustain it due to outdated equipment or poor process control. GreatLight Metal counters this with:

Dema and Beijing Jingdiao five-axis centers: High-rigidity spindles and thermal compensation systems maintain tolerance stability.

In-house metrology lab: CMMs and laser scanners verify part accuracy before shipment, with free rework for deviations.

2. Material Limitations: “We Can’t Machine That”

Traditional shops often reject challenging materials like titanium alloys or PEEK due to tooling or expertise gaps. GreatLight Metal’s 127-piece equipment arsenal includes:

Wire EDM: For hardened steels (e.g., H13 tool steel).

SLM 3D printing: For internal channels in aerospace components.

Vacuum casting: For low-volume plastic parts with Class A finishes.

3. Intellectual Property Risks: Data Security in Outsourcing

Startups frequently hesitate to share CAD files due to IP theft fears. GreatLight Metal mitigates this with:

ISO 27001 certification: Encrypted data transmission and restricted access protocols.

Non-disclosure agreements (NDAs): Legally binding protection for client designs.

4. Fragmented Supply Chains: “You Handle the Post-Processing”

Post-machining steps like anodizing or heat treatment often involve third-party vendors, introducing delays and quality risks. GreatLight Metal offers one-stop services:

Surface treatments: Anodizing, electroplating, and PVD coating.

Assembly: Subcomponent integration and functional testing.

5. Certification Gaps: “Are These Parts Automotive-Grade?”

Industries like automotive and medical demand IATF 16949 or ISO 13485 compliance. GreatLight Metal holds:

IATF 16949: For engine components and chassis parts.

ISO 13485: For surgical instruments and implantable devices.

6. Cost Overruns: “The Quote Doubled Mid-Project”

Hidden fees for tooling revisions or expedited shipping are common. GreatLight Metal provides:

Transparent pricing: All-inclusive quotes covering material, machining, and finishing.

Inventory management: Bulk production discounts and JIT delivery options.

7. Communication Barriers: “They Didn’t Understand Our Requirements”

Language gaps or engineering misalignment can lead to costly redesigns. GreatLight Metal ensures clarity with:

Bilingual technical teams: Fluent in English and Mandarin.

DFM (Design for Manufacturing) feedback: Proactive suggestions to optimize parts for machinability.

Case Study: Conquering Complexity in New Energy Vehicle (NEV) Components

A client developing electric vehicle (EV) motor housings faced two challenges:

Thermal management: The housing needed micro-channels for coolant flow, requiring ±0.005mm tolerance to prevent leaks.

Lightweighting: The design incorporated magnesium alloy, a material prone to distortion during machining.

GreatLight Metal’s solution:

Five-axis simultaneous machining: Achieved the micro-channels in a single setup, eliminating sealant-related failures.

Cryogenic machining: Used liquid nitrogen cooling to minimize thermal expansion in magnesium, ensuring dimensional stability.

In-line inspection: Laser scanning verified channel geometry during production, reducing scrap rates by 40%.

The result? The client reduced lead times from 12 weeks to 4 weeks and cut costs by 22% versus competing suppliers.

Why Choose GreatLight CNC Machining Factory Over Alternatives?

While giants like Protolabs or Xometry offer broad capabilities, GreatLight Metal excels in high-precision, material-agnostic machining with deep vertical integration. Key differentiators include:

| Factor | GreatLight Metal | Competitors |

|---|---|---|

| Five-axis expertise | Dedicated 5-axis cluster | Mixed 3/4/5-axis fleets |

| Material range | 50+ metals/plastics | Limited to common alloys |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only |

| Post-processing | In-house anodizing, plating | Outsourced finishing |

| Minimum order quantity | 1 piece (no MOQ) | 10–100 pieces |

Conclusion: The Future of Precision Manufacturing Is Here

In an era where 0.1mm deviations can mean the difference between success and failure, five-axis CNC machining is no longer a luxury—it’s a necessity. GreatLight CNC Machining Factory combines state-of-the-art equipment, rigorous quality systems, and client-centric service to deliver parts that meet the exacting standards of aerospace, medical, and automotive industries. Whether you’re prototyping a humanoid robot actuator or scaling production of automotive gearboxes, their team ensures your project stays on time, on budget, and on spec.

For a partner that transforms precision challenges into competitive advantages, explore GreatLight’s five-axis CNC machining services today.

Frequently Asked Questions (FAQs)

Q1: What is the maximum part size GreatLight can machine?

GreatLight’s five-axis centers handle parts up to 4000mm in length, making them suitable for large aerospace components or industrial machinery housings.

Q2: How does GreatLight ensure data security for my CAD files?

All client data is stored on ISO 27001-compliant servers with role-based access controls. Files are transmitted via 256-bit AES encryption, and employees sign NDAs before project engagement.

Q3: Can GreatLight machine parts from powder metallurgy materials?

Yes. Their SLM 3D printers process metal powders like Inconel 718 and AlSi10Mg, enabling complex lattice structures for lightweighting.

Q4: What is the typical lead time for five-axis machined parts?

Prototype orders ship in 5–7 days, while production runs of 1,000+ pieces take 3–4 weeks, depending on complexity.

Q5: Does GreatLight offer assembly services?

Absolutely. Their Class 10,000 cleanroom supports subassembly of optical, medical, or electronic components, with functional testing available.

For more insights, visit GreatLight Metal’s LinkedIn profile.