Considering the process optimization and flexible process design challenges faced by manufacturing complex aviation structural parts, from traditional single-machine processing to flexible production line processing and process design for flexible production control and process solutions for unmanned flexible processing design, a set of comprehensive process design solutions suitable for flexible production of complex aviation structures have been formed, which effectively improves the processing efficiency and quality of aviation structural parts complex in multi-variety and small batch production modes.

1 Preface

The rapid development of China’s aviation industry has put forward higher requirements for the processing efficiency and quality of aviation structural parts. As an important connecting and load-bearing structure of aircraft, aviation structural parts are widely processed using CNC machine tools. Compared with CNC products in other industries, complex aviation structural parts have the characteristics of complex product structure, multiple varieties and small batches. Special equipment and tools are mainly used for processing, and the degree of specialization and integration is low.[1]. In order to improve the production efficiency of complex aviation structural parts, it is necessary to introduce more advanced processing and manufacturing technologies and process design solutions.

As a new manufacturing technology, flexible manufacturing technology has been applied in many fields such as machine manufacturing and component assembly. In our country, the application of flexible manufacturing technology in the field of aircraft manufacturing is still in the exploratory stage.[2]Many domestic aviation companies have successively carried out application research on flexible production line technology. A flexible production line is an automated production line involving the entire CNC processing process of the product, composed of fixed machine tool equipment as the main body and equipped with corresponding material conveying devices, computer control systems , warehouses for storing materials, etc.[3]with the characteristics of strong product flexibility, flexible production schedule, stable product quality and high degree of automation. This article takes complex aviation structural parts as the research object, analyzes the structural characteristics and processing processes of products processed on flexible production lines, and realizes the design and planning of processing processes for quality control. flexible production in response to automated production requirements during flexible production. online processing. Flexible production of complex structural parts for aviation provides a comprehensive set of overall process design solutions.

2 Process design for flexible production of multi-family aerospace structural parts

When operating a flexible production line, automated control of product processing processes is the core of flexible production, and reasonable processing process design is the key process of production line process design. production. The product processing process is a control document that defines the entire product process in the production line. The production control system of the flexible production line realizes automatic production planning and unmanned processing of the product by calling the corresponding processing process according to the plan. information about the order request.

The first aspect of designing the process flow of a flexible production line is that the production of aeronautical products has strict requirements for information traceability for the entire parts manufacturing process. Therefore, at the beginning of the process flow design of a flexible production line, it is first necessary to formulate the unique control. and control the processing of process flow control documents Edit rules. Taking the part drawing number as the main body, process control documents design different numbering rules according to different processing processes and carry out versioning to ensure the traceability of product information. Taking the part with drawing number SYJ01 as an example, the suffix for single part processing is _DJ, the suffix for nesting processing is _TL, and the versions are A, B, C… and so on. immediately. the one-piece processing technology of this part The process file is named: SYJ01_DJ_A, and the file number is unique in the production line.

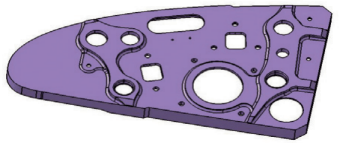

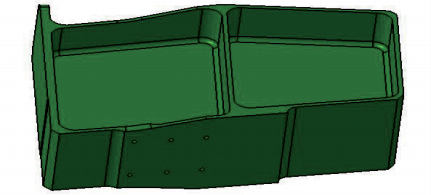

The second aspect of flexible design of production line processes is to take into account product diversity. Due to the complex structure and diverse categories of aeronautical products, when designing the online process flow, grouped part families should be divided based on the similarity of part structures. Based on this, the group process should be used to design the treatment. plan. Based on process similarities, it is possible to design flexible tooling suitable for more part families, thereby solving the problems of large numbers of special tooling, tedious clamping and complex processing operations. traditional.[4]. As shown in Figure 1, the two product families with different structures, the reinforced partition and the machined frame section, are processed using two front and rear stations. The same clamping pattern and tooling will be used in the flexible production design. online process flow. And adopt the same set of process flows.

a) Reinforced partitions

b) Section framed by the machine

Figure 1 Merging product families based on process similarity

The third aspect of flexible production line process flow design is to optimize the online process design based on the configuration of process resources on the flexible production line. Factors that limit the processing of flexible production line products include wool, tooling, cutting tools, machine tool equipment and processing procedures. Before the product is processed online, the preparation of corresponding cutting tools, tooling and processing procedures must be completed. wool is stored and loaded, the production control system must. According to the differences in demand quantity and delivery time of different products, the priority of production planning is automatically designed and the appropriate machine tool is selected for processing. Based on the principle of meeting processing needs, it is possible to reduce the number of required tools and tools, improve the efficiency of CNC programs, simplify processing stations and optimize the design of process.

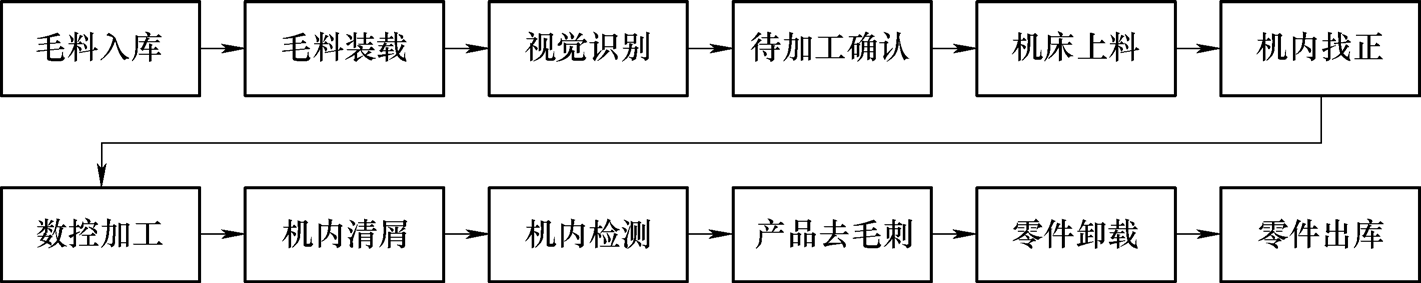

Product processing on the flexible production line is guided by the product process flow, from the wool entering the warehouse to the completion of parts processing and delivery. The flow process of products processed in a single station of the production line is shown in Figure 2. For products processed in multiple stations, after the processing of a certain station is completed, the semi-finished blanks are stored under form of virgin wool for storage management. Depending on the production order, the above process is repeated until all stations are processed.

Figure 2 The single-station processing product flow process

3 Design of process solutions for flexible and unmanned processing of complex aviation structural parts

Automated product processing on flexible production lines relies on flexible process design. Based on the stability and reliability of the product’s CNC machining program, it includes flexible tooling design, external clamping solutions for wool materials, automatic alignment solutions, tool management solutions , automated continuous processing solutions, in-machine inspection and in-machine chips. deletion, etc.[5]The whole process is written into the process flow file to achieve flexible and unmanned processing of complex aviation structural parts.

3.1 External tightening and quick replacement

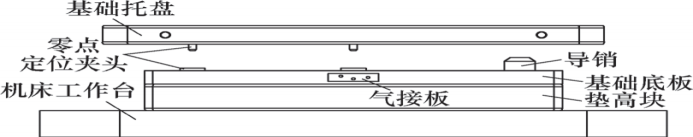

In a flexible production line, preparation for clamping parts must be carried out outside the production line. Once loading is complete, the wool and tooling must be fed into the machine tool together. The tooling and wool as a whole must be positioned and clamped precisely and quickly in the machine tool. At present, zero point positioning technology is widely used to solve the problems of rapid disassembly and precise positioning of tools. The zero point vane assembly is shown in Figure 3. A combined tooling assembly based on the zero point positioning structure can be designed. The basic base plate is fixed on the machine tool table via lifting blocks equipped with wool. or other luminaires is guided by guide pins. The zero point positioning chuck can quickly position and tighten the base plate to achieve rapid replacement.

Figure 3 Pallet assembly diagram at zero point

3.2 Automatic alignment and online measurement

During the processing of the flexible production line, it is necessary to transform the process of manual control of handwheels and buttons by the operator, as well as manual alignment and adjustment of the workpiece coordinate system to the using edge feelers, dial indicators, feelers, etc. , in the automatic operations of the program. In the automated production line, the machine tool is equipped with a machine probe. By developing post-processing software, the CNC program is used to drive the probe to measure different features such as straight edges, holes and planes of the wool, as well as the processing coordinate system is defined.

The online measurement function introduces a measurement macro program to measure the dimensional position after semi-finishing, writes the measured value to the machine tool, compares the difference, and performs dynamic processing compensation. After processing is completed, the online measurement function can measure and record the actual processing dimensions of parts and provide quality warning when dimensions are out of tolerance.

3.3 Tool control plan

In flexible production lines, there are special requirements regarding the specifications and quantity of cutting tools used for processing. In order to facilitate tool management and detection, tool names are specified uniformly according to tool types and specifications to ensure the uniqueness of tool names and form a tool database standardized. The flexible production line is also equipped with a dedicated tool monitoring system, which can carry out statistical analysis of tool cutting vibration and tool life, rapid tool replacement, and effectively avoid tool quality problems. product caused by tool wear and damage. Conventional tool selection only takes into account the structural features and processing characteristics of the workpiece. Since the number of tools that can be stored in the machine tool magazine is limited, tool specifications must be incorporated into the process plan design. In actual use, only when the tool name called by the program is the same as the tool name stored in the machine tool magazine can the automatic tool call be completed.

3.4 Automatic chip cleaning solution

During the CNC machining process, the accumulation of chips will cause the final surface quality of the product to deteriorate or even cause the tool to stick, causing product quality problems. A certain type of powerful machine fan is selected, and the fan is stored and managed like a tool. During processing, the chip blowing program is called to remove chips during workpiece processing and ensure processing continuity. At the same time, since the chips cannot be removed when the pallet comes off the line, a chip cleaning macro program is made according to the actual working conditions of on-site processing. After the fan is fixed at a fixed angle, the C-axis of the machine tool rotates, so that the chips on the workpiece, pallet and machine tool can be cleaned in place.

3.5 Automatic serial processing solution

The automatic program call relies on the functions of the Siemens 840D CNC system and must be combined with the production control system. Prepare a master CNC machining program that matches the production control system. Apply the subroutine call function to realize the calling of various subroutines. At the same time, you need to add program information, subroutine names, tool names and other information comment lines for the. production control system at the pre-reading of the main program. By prefetching the information, the production control system can determine whether the subroutine exists and whether the tool names match. Only when the information matches one by one can the main program be called correctly and the production order and processing process can operate normally. be completed.

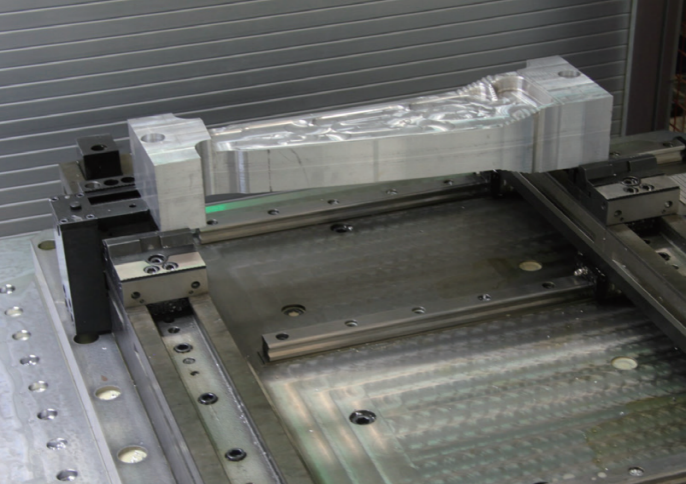

4 application files

Select the aircraft reinforced rib parts and carry out online processing tests on the flexible production line. Prepare process flow documents for typical parts and import them into the flexible production line’s production control system for automated product process calls. From offline clamping of the blank (see Figure 4) to the end of product processing, the feasibility of unmanned flexible processing of the product in the flexible production line was verified. This solution can significantly improve the utilization of machine tools and significantly improve product processing efficiency.

Figure 4 External tightening of the blank

5 Conclusion

The transformation of traditional single-machine processing into flexible automated processing is a major advancement in aerospace structural part processing technology. This article lays the foundation for transforming process control from manual process control to automated control systems through process design for flexible control of multi-family aerospace structural part production. On this basis, through the design of external clamping and quick change solutions, as well as the development and design of processes for flexible and unmanned machining of complex structures such as adaptive alignment, tools, automatic chip removal control and automatic process detection control, it will be Automated and flexible processing of complex aviation structural parts becomes possible.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.