Deciphering 3D printing in titanium (2)

In this article, Mohou.com will work with you to understand what’s available todayWho uses titanium?3D printing? These manufacturers produce a wide range of products, from medical and military equipment to high-performance bicycles and consumer electronics. What they all have in common is the desire to offer lightweight yet strong products through innovative (often custom) designs.

Recently, titaniumThe biggest news in the world of 3D printing is that Apple’s latest iWatch will reportedly use the technology. According to an unconfirmed report from financial services analyst Ming-Chi Kuo, who gathered intelligence from Apple’s supply chain contacts in Asia, the tech giant will adopt the powered Apple Watch Series 10 by Bright starting in the second half of 2024. 3D printed titanium parts produced by Laser Technologies (BLT). Kuo said Apple and BLT have been experimenting with 3D printing in titanium for years to streamline the process.

picture1:Incus and Element22 demonstrate titanium 3D printing of smartwatch cases using photolithography-based metal fabrication (LMM) technology (Source: Incus)

A,Medical and dental implants

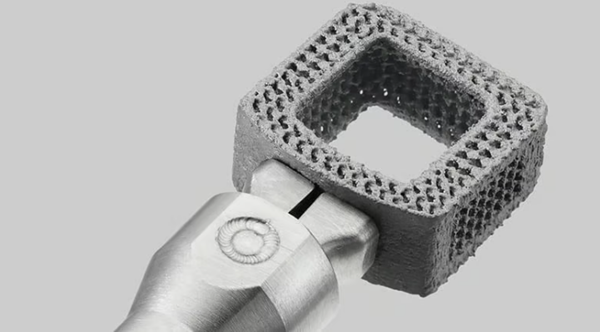

Figure 2

As medical product manufacturers increasingly adopt additive manufacturing technology for their production, the U.S.The number of FDA-approved titanium-based 3D printed surgical implants continues to grow.

In the medical industry,3D printed titanium implants have been used successfully in the spine, hips, knees and extremities due to the metal’s inherent biocompatibility and good mechanical properties, combined with the ability of 3D printing to personalize porous structures (allowing bone integration) and on a large scale. better outcomes for patients.

3D printed titanium implants are growing in popularity and popularity. Since most medical implants are intended for large numbers of people with the same disease, they are not suitable for everyone. People with rare diseases are often excluded. Now, thanks to 3D printing, it is possible to produce implants designed specifically for individual patients.

hospital for special surgery in new york(HSS) reported earlier this year that it was 3D printing custom titanium joint replacements for extremely complex cases where standard implants fail. HSS is the first hospital in the United States to have a 3D printing facility.

In 2023, a British surgeon performed four wrist operations on the same day, using patient-specific 3D printed titanium plates to correct previously fractured wrist deformities. Dr Akshay Malhotra, consultant orthopedic surgeon and clinical lead for hand and wrist surgery at University Hospitals of the North Midlands, said: “Once this planning process is complete, bespoke titanium plates will be hand printed. using titanium powder, then tested, shipped to UK and shipped to UK. Spayed at the county hospital in preparation for surgery.

picture3:CoreLink’s 3D printed titanium screws have a porous structure that promotes bone growth, and the image on the right is the new specialized titanium joint provided to patients by the FingerKit consortium.

In 2022, doctors at Manipal Hospital in India received a cancer patient whose tumor was destroying his chest, so they began using a 3D printed titanium alloy. Normally, implants of this size would be too heavy for the human body, but because titanium is so light and strong, a custom replacement weighing less than 250 grams can be 3D printed for the patient. Thanks to the success of the 3D printed implant, the patient made a full recovery and was able to return to his normal life without relying on external machines to help him breathe.

Used in a patient-specific contextPatients report positive results in trial of 3D printed titanium talus for ankle bone replacement surgery. Bone replacement means that patients do not need a complete ankle replacement. The anatomical characteristics of the talus are very patient specific, requiring the design of unique 3D parts based on the patient’s CT data.

In 2023, the US FDA approved a number of 3D printed titanium implants, most of which are spinal implants.

Restor3d will receive approval in 2023 to launch the first patient-specific 3D printed ankle replacement device made entirely of metal (titanium).

SurGenTec will receive approval for its 3D printed titanium posterior sacroiliac joint fusion system, TiLink-P, in 2023.

FloSpin e will receive FDA approval in 2023 for a 3D printed implant to support the spine called the Tri-Largo Cervical Interbody Fusion System.

Eminent Spine will receive FDA approval in 2023 for its 3D cervical interbody fusion system using a 3D printed titanium alloy framework.

ChoiceSpine will receive FDA approval for its Blackhawk Ti 3D printed titanium cervical spacer system in 2023.

CoreLink is expected to receive FDA approval in 2023 for its Siber Ti sacroiliac joint fusion system, which consists of a 3D printed porous nanosurface titanium implant.

two,aerospace

picture4:GKN Aerospace plans to add a new large-scale titanium 3D printer to its Texas factory (Source: GKN Aerospace)

In the aerospace industry, there are currently a variety of titanium-based additively manufactured parts for commercial and military use, with many additional prototypes pending.FAA certified. 3D printed titanium is valued for its low buy-to-fly ratio – an aerospace term that refers to the correlation between the weight of the starting material and the weight of the printed part.

Several specialist subcontractors in the aerospace, defense and space markets, e.g.Primus Aerospace, StarHagen Aerospace and Zeda have all invested in 3D printers capable of producing titanium components for prototypes and final parts.

picture5:becauseNASA only needs one, so 3D printing a titanium bucket for a cold-actuated lunar deployable arm makes more sense than traditional manufacturing (Source: NASA Jet Propulsion Laboratory)

two,Bicycles and consumer goods

picture6

NOW,3D printed titanium is found almost everywhere in high-performance bikes because every ounce of weight counts and high strength is essential. Used in cranks, brake levers, stems, derailleur hangers and even entire frames, titanium has proven to be as strong as aluminum and as light as carbon fiber without the durability issues of carbon fiber.

Recently, bicycle manufacturersRibble launched the Allroad Ti with a 3D printed frame, which the company says “allows us to hand-craft titanium tubes with much more advanced aerodynamics than standard round tubes on a typical titanium frame.” 3D printing also allows Ribble to eliminate welds.” seams, invisible cable routing and integration of parts.

Based in New YorkNo.22 Bicycle Company has focused on the production of titanium alloy bicycles for many years. The company launched the Reactor Aero in August. This bike incorporates several 3D printed titanium alloy parts and will be officially launched in 2025. No.22 co-founder Bryce Gracey said in a press release: “3D printing titanium has structural properties extraordinary. The ability to print internal support structures anywhere on the frame gives us unprecedented control over ride quality. »

Speaking of complete frames, bicycle manufacturersAngel Cycle Works has 3D printed a lightweight, all-titanium frame, which the company says allows for faster race times and allows for new design geometries. The company’s new superbike is called Heaven and weighs 400 grams less than the previous version. Another all-titanium frame from Pilot, launched this year, is called Pilot Seiren. The road bike frame is entirely 3D printed in titanium (divided into three parts). The company says 3D printed titanium allows it to customize the bike to the rider’s preferences, without the frame needing painting or coating.

Carbon Wasp explains why it ditched aluminum and carbon fiber in favor of 3D printed titanium for its latest aftermarket crank arms: “We found all kinds of creative ways to attach the crank to the driveshaft without having to tighten it in pressed carbon. carbon fiber, but I always had to add metal inserts… but I had many problems bonding the inserts to the carbon fiber. “After some prototyping, Carbon Wasp discovered 3D printing titanium-filled mesh. The crank is as light as carbon fiber but is stronger in impact-prone areas. “We still think carbon fiber is the best material for many other uses, including frames… but we are already investigating other titanium components.”

picture7:bicycle companyMythos offers its customers a range of 3D printed titanium parts, including this handlebar, while at Verve Cycling (right) they offer a new 3D printed titanium crank.

The Pilot’s Tim Blankers told the Road.cc website: “The printing process helps reduce wall thickness, resulting in a lighter, stronger frame with no stress points. The frame weighs a little more of one kilogram The Pilot is OK Adding material where stiffness is needed to optimize power transfer.

Chinese bicycle maker Hanglun said it wouldIncrease investment in titanium 3D printing in 2024. The company said: “We plan to use 3D printing technology to produce titanium bicycle frames and parts, with an annual output of more than 50 000 pieces. These parts will be applied to several bicycle models, with the aim of providing customers with stronger and lighter parts. » and more durable bikes. Durable titanium bicycle products.

There are a large number of bicycles on the market3D printed titanium alloy parts:

Silca launched its latest range of 3D printed products earlier this year, which includes a range of titanium transmission mounts.

Verve Cycling and Metron Additive Manufacturing have launched a 3D printed titanium crank called InfoCrank 3D Ti.

Moots has launched new 3D printed titanium forks and accessories for its new Routt CRD gravel bike.

Cane Creek has unveiled new 3D-printed titanium Electric Wings cranksets that are as light as a carbon fiber crankset but as durable as an aluminum crankset, the company says.

picture8:Japanese golf brandTitanium golf clubs 3D printed by the designer (Source: Farsoon)

Japanese golf brandDesigner launched a 3D-printed titanium golf club earlier this year that it says will offer golfers greater distance, greater accuracy, greater stability and greater forgiveness. The titanium club head is manufactured using Farsoon Technologies’ dual-laser powder bed fusion 3D printer.

Four,manufacturing

semiconductor manufacturerASML turned to 3D printing titanium for completely different reasons and now its titanium support tray preforms (used in wafer production) are 3D printed rather than forged, saving 64 % of raw materials and speed up delivery. Metal additive manufacturing company Norsk Titanium is using a directed energy deposition (DED) platform to print 80 kilograms (about 176 pounds) of near-net shape preforms – used in the production of semiconductor wafers – with Ti64.

Norsk worked with its Dutch partner Hittech Group to develop the preform, which Norsk says is used in ASML’s lithography systems. ASML, also based in the Netherlands, has been one of the most talked about companies in the world due to the chip shortage in recent years. Specifically, ASML is known for producing the world’s only extreme ultraviolet (EUV) lithography machines.

picture9:Made at the University of Washington3D printed titanium alloy wheel carrier (Source: University of Washington)

Even the US Navy started using it3D print titanium to save time and money and eliminate dependence on foreign supply chains. Without domestic capabilities to manufacture the large titanium castings needed for high-performance centrifugal pumps, the Navy faces long lead times and a supply chain that uses expensive, carbon-intensive titanium raw materials. But soon, with the emergence of new domestic partners IperionX Recycling Titanium Powder and Carver Pump Additive Manufacturing, the Navy will be able to significantly reduce delivery times for critical components, increase equipment availability and sustainably restore the critical US titanium metal supply chain.

five,Precision products, electronics and jewelry

picture10:3D printed titanium alloy hinge cover used in Honor Magic V2 2023 foldable smartphone (Source: Honor)

3D printing can create complex, very thin-walled titanium parts, which is why it is used to make watch cases, such as Panerai and Holthinrichs watches (pictured above).

In 2023, smartphone maker Honor launched its new Magic V2 foldable phone, which uses a 3D-printed titanium alloy hinge cover that is lighter and 150% stronger than the previous aluminum version. The company says this small piece of titanium, which can be 3D printed tens of thousands of times, is key to the product’s durability and smooth folding and unfolding.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.