Prague, the capital of the Czech Republic, is a142kilometers of infrastructure every day in the city, or approximately991Cars crisscross the road carrying residents and tourists. As a result, the Prague Transport Company is responsible for operating trams and metros and keeping them up to date, looking after all stations and stations.

2022Year9moon16day, in Prague7a neighborhood namedStromovkasite, a3Dprinted bench in brief36It was produced in a matter of hours and unveiled last weekend. Interestingly, this tram shelter is the first tram shelter produced using additive manufacturing technology in the Czech Republic.

This innovative bus stop was designed by the Prague companySo concreteProduced and built by the company that supplies the benches and standing pavilions to the city of Prague free of charge. The prototype, which will now allow passers-by to sit while waiting for the next tram, is made from concrete with special properties: it is ten times more resistant than conventional concrete, hence its name ultra-concrete. resistant. Politician in charge of transport in PragueAdam ScheinherrRIGHT3DEnthusiastic about the benefits of printing for Prague, he explained:“Combine this concrete with3DCombined with printing, it is a method of using concrete only where absolutely necessary. It is a change in the project approach that sets a direction towards meeting the conditions of sustainable development. Don’t waste energy and resources that are becoming increasingly scarce.“

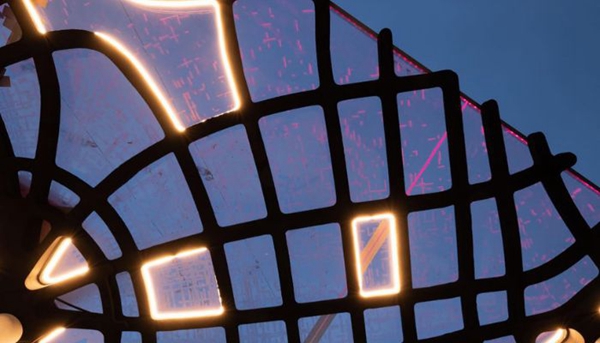

△Passers-by can sit under the cover of an additively manufactured tram stop

About Prague3DPrint tram stop details using this3DThanks to printed manufacturing methods, the city of Prague can benefit from a new way of sustainable building. In addition, from an economic point of view, the building can achieve greater efficiency. In this case just use60%materials, and at the same time in terms of human labor, it can also be reduced to a minimum. exist3DOnce printing is complete,So concreteThe company transported and then assembled the various parts printed in concrete, which now represents a completely new type of tram station. However,3DPrinting was not used for all builds. Instead, the entire design is optimized using artificial intelligence, and only at the end is human power used to make changes.

Concerning the maintenance of the new tram shelters,So concreteThe company claims that the roof requires no maintenance as the materials used are extremely durable.So concretegeneral manager of the companyFederico DiazFurther details about this material and its applications were introduced, and it was felt that this material could be used100years, or even more. This material has a very long lifespan and is already used, for example, in the construction of dams. As the bus shelter already welcomes many customers, the city is sure that it will not be the last to be used3DPrinting technology for architecture. Additionally, they are already planning other projects such as constructionStvanickáfootbridge, reconstructionBarrandovQiaoheLiveN bridge.

△The tram shelter is finished3DDesigned and produced by printing and artificial intelligence

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.