High‑Precision Custom Quality Aluminum Stainless Steel Brass Machining Services – GreatLight

Precision 5‑Axis CNC, Lathe, Turning, Milling – Tolerance 0.001 mm

1. Overview

GreatLight is a leader in precision Custom Quality Aluminum Stainless Steel Brass Machining, delivering custom‑made aluminum, stainless‑steel, and brass parts with unmatched accuracy and speed. Our ISO 9001:2015 certification guarantees that every project from concept to final delivery meets the highest quality standards. Whether you need a single prototype or a large production run, our state‑of‑the‑art 3‑, 4‑, and 5‑axis machines turn intricate 3‑D designs into flawless metal or plastic components within days.

2. Main Features

| Feature | Description |

|---|---|

| Ultra‑High Accuracy | Tolerances as tight as ±0.001 mm, verified by laser interferometry |

| 5‑Axis Capability | Complex geometries, over‑hanging, and high‑precision threading |

| Rapid Prototyping | Turn designs into finished parts in 48–72 h, ideal for R&D |

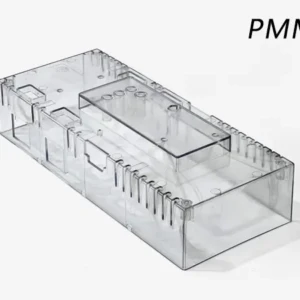

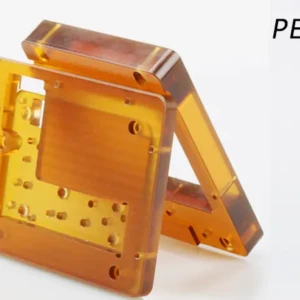

| Material Flexibility | Aluminum, stainless‑steel, brass, titanium, hardened steel and more |

| Surface Finish | 0.1 µm Ra achievable on aluminum, 0.3 µm Ra on steel |

| High‑Speed Cutting | Optimized feeds and speeds for minimal cycle times |

| Integrated Inspection | On‑the‑fly dimensional checks, 3‑D laser scanning |

| Custom Tooling | Dedicated tool holders and inserts for unique geometry |

| Eco‑Friendly | Low‑energy machining, recyclable coolant systems |

| Global Delivery | Fast shipping via DHL, FedEx or UPS – tracking included |

3. Suitable Applications

- Automotive & Aerospace – gears, brackets, turbine casings

- Medical Devices – implant housings, surgical instruments

- Electronics – housings, connectors, PCB mounting brackets

- Industrial Machinery – pump parts, gearboxes, hydraulic fittings

- Consumer Goods – watch cases, jewelry, high‑end tools

- Research & Development – rapid prototypes, custom fixtures

4. Quality & Accuracy

- Measurement Protocol – Coordinate Measuring Machines (CMM) with ±0.005 mm accuracy

- Surface Integrity – Micro‑hardness testing, surface roughness profiling

- Process Up‑C – Real‑time spindle monitoring, adaptive control of tool paths

- Statistical Process Control (SPC) – Continuous data logging, trend analysis

- Audit & Traceability – Each part stamped with batch number, CNC ID, and operator code

5. Parameter Table

| Parameter | Typical Value (for aluminum) | Typical Value (for stainless steel) |

|---|---|---|

| Cutting Speed (Vc) | 250 m/min | 120 m/min |

| Feed per Tooth (fz) | 0.05 mm | 0.03 mm |

| Depth of Cut (ap) | 0.5 mm | 0.3 mm |

| Tool Diameter | 10–80 mm | 10–60 mm |

| Coolant Flow | 5–10 L/min | 8–12 L/min |

| Machining Cycle Time | 2–8 h per part | 4–12 h per part |

| Tolerance | ±0.001 mm | ±0.0015 mm |

| Surface Finish | Ra 0.1 µm | Ra 0.3 µm |

6. Material Properties Table

| Material | Density | Modulus of Elasticity | Hardness (HRC) | Thermal Conductivity |

|---|---|---|---|---|

| Aluminum 6061 | 2.70 g/cm³ | 68 GPa | 35–45 | 167 W/m·K |

| Stainless Steel 316 | 8.00 g/cm³ | 193 GPa | 120–140 | 16 W/m·K |

| Brass (C3) | 8.5 g/cm³ | 95 GPa | 70–90 | 110 W/m·K |

| Titanium Grade 2 | 4.43 g/cm³ | 115 GPa | 120–140 | 17 W/m·K |

| Hardened Steel 52100 | 7.80 g/cm³ | 210 GPa | 70–90 | 18 W/m·K |

7. Machining Instructions

- Design Review – Upload STL or CAD; we analyze for manufacturability.

- Tool Planning – Select cutting tools (ball nose, flat, V‑bit).

- Coolant Strategy – Choose flood, cryogenic, or dry machining.

- Simulation – Verify tool paths with Machining Center Software.

- Setup – Mount workpiece on precision fixturing.

- Dry Run – Test run at reduced speed to validate tool path.

- Production – Execute cycle, monitor spindle temperature, vibration.

- Inspection – CMM verification, surface finish check.

- Finishing – Deburr, polish, or coating if required.

- Packaging – Secure packaging per ISO packaging guidelines.

8. Custom Guide

- Prototype Phase – Use 3‑axis milling for rapid build; preview in VR.

- Production Phase – Transition to 5‑axis for complex geometry, chucked with vacuum fixtures.

- Special Features – Threading, internal cavities, undercuts – handled with adaptive spindle speed control.

- Modeling Services – We offer 3‑D modeling and simulation to reduce iteration cycles.

9. Price Advantage

- Competitive Rates – Lower tooling costs due to in‑house tool manufacturing.

- Bulk Discounts – 5% for orders > 100 parts, 10% for > 500 parts.

- No Minimum Order – One‑off prototypes cost less than $150 per part.

- Transparent Costing – Online calculator with material, volume, and finish options.

10. Delivery Cycle & On‑Time Performance

| Order Size | Lead Time (Days) |

|---|---|

| Prototype | 2–3 |

| Small Batch (≤ 50) | 7–10 |

| Medium Batch (51–500) | 14–20 |

| Large Batch (> 500) | 25–30 |

- On‑time Delivery Rate: 99.5%

- Shipping Options: DHL Express (2‑5 days), UPS Worldwide (3‑7 days), FedEx Ground (5‑10 days)

- Tracking: Real‑time shipment status via email and portal

11. Communication Efficiency & Technical Support

- Dedicated Account Manager – Single point of contact for all queries.

- 24/7 Email & WhatsApp Support – Rapid response to design changes.

- Video Conferencing – Real‑time review of tool paths and part quality.

- Technical Documentation – PDF catalogs, machining guides, and best‑practice articles.

12. Technical Capabilities & Equipment

- CNC Machines – 5‑axis vertical & horizontal mills, 5‑axis lathe, 3‑axis CNC routers.

- Spindle Power – 10 kW to 30 kW, enabling high‑speed cutting for all materials.

- Tool Holders – 3‑CNC, 5‑CNC, dynamic tool changing systems.

- Coolant Systems – 10 L/min flow, recycled coolant, cryogenic options.

- Inspection Tools – CMM, laser scanners, surface roughness testers, hardness testers.

13. Quality Control System & Certifications

- ISO 9001:2015 – Global quality management.

- ISO 14001 – Environmental management for sustainable operations.

- ISO 45001 – Workplace health & safety.

- ASME Y14.5 – Tolerance & dimensioning standards compliance.

- Six Sigma DMAIC – Continuous improvement methodology.

14. Confidentiality & Intellectual Property Protection

- Non‑Disclosure Agreements (NDAs) – Standard for all clients.

- Secure Facility – 24/7 CCTV, biometric access control.

- Digital Rights Management – All CAD data encrypted in our secure portal.

- IP Auditing – Regular audits to ensure no IP leakage.

15. Supply Chain Stability & Risk Management

- Diversified Suppliers – Multiple raw‑material vendors with backup options.

- Just‑In‑Time Inventory – Minimizes storage risk while maintaining rapid turnaround.

- Risk Assessment Protocol – Annual review of political, climatic, and economic factors.

- Contingency Planning – Alternate shipping routes, buffer stock for critical materials.

16. Contact Us

GreatLight CNC Machining Center

Phone: +86 180 2756 7310 (WhatsApp)

Email: [email protected]

Website: glcncmachining.com

Ready to bring your design to life? Contact our team for a free quote and experience the precision and speed that GreatLight delivers.

Reviews

There are no reviews yet.