Custom CNC Precision Machining Service

In the realm of precision parts machining and customization, finding a reliable and capable partner is crucial for success. GreatLight CNC Machining Factory, established in 2011, has positioned itself as a leader in this field, offering advanced five-axis CNC machining services tailored to meet the unique needs of various industries.

Advanced Technology and Equipment

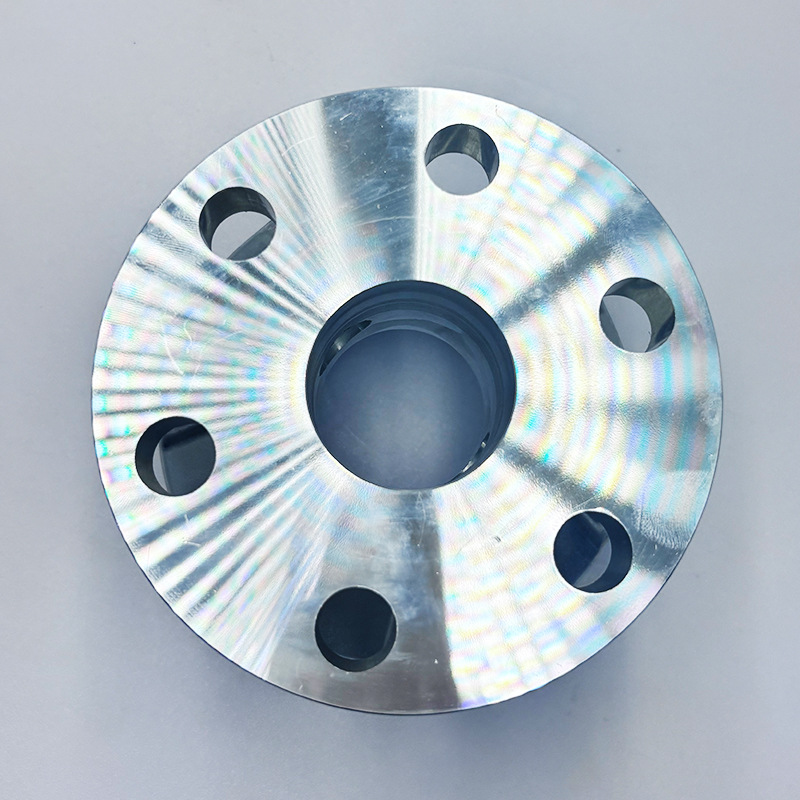

GreatLight CNC Machining Factory boasts a comprehensive arsenal of advanced equipment, including 127 pieces of precision peripheral devices. Our fleet of high-precision five-axis, four-axis, and three-axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and 3D printers (SLM, SLA, SLS) ensures that we can handle even the most complex machining tasks with precision and efficiency.

A Wide Range of Services

Our services encompass a wide range of precision manufacturing needs:

Precision CNC Machining: Three-axis, four-axis, and five-axis machining services.

CNC Milling Services: For intricate designs and complex geometries.

Die Casting Mold/Metal Die Casting Processing: For high-volume production.

Vacuum Casting Customization: For lightweight and complex parts.

Sheet Metal Processing Customization: For various applications.

3D Printing: Stainless steel, aluminum alloy, titanium alloy, and mold steel printing.

Rapid Prototyping: Nearly a hundred processing services and comprehensive solutions.

One-Stop Surface Post-Processing Services: Ensuring the final product meets the highest standards.

High Precision and Quality Assurance

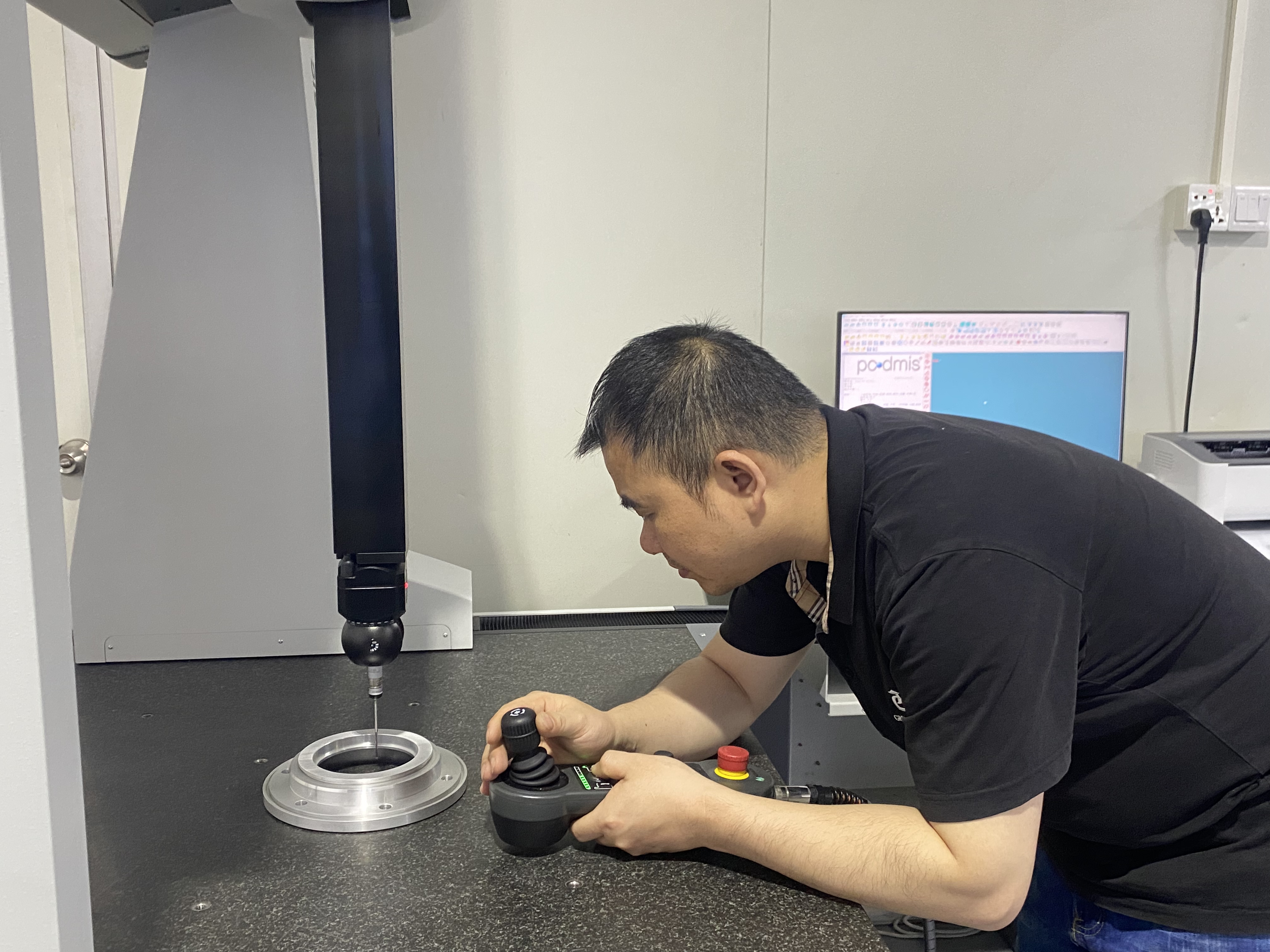

GreatLight CNC Machining Factory is committed to delivering the highest level of precision and quality. Our machining capabilities reach ±0.001mm, ensuring that every part meets your exact specifications. We are ISO 9001:2015 certified, adhering to strict quality standards and utilizing advanced technology to ensure precision and accuracy in manufacturing.

Comprehensive Quality Management Systems

Our commitment to quality is further reinforced by our compliance with multiple international standards:

ISO 9001:2015: Ensures product quality meets international standards.

ISO 27001: Data security compliant for intellectual property-sensitive projects.

ISO 13485: Medical hardware production compliant.

IATF 16949: Specifically for the automotive and engine hardware component industries, focusing on improving quality and reducing waste.

Real-World Applications and Success Stories

GreatLight CNC Machining Factory has extensive experience in various fields, including humanoid robots, automotive engines, aerospace, and more. Our technical expertise and comprehensive service capabilities have made us a trusted partner for many leading companies.

Use Case: Empowering New Energy Vehicle Innovation

One of our notable projects involved manufacturing complex e-housing components for an innovation-focused company specializing in new energy vehicles. Our team successfully overcame the challenges posed by the intricate design and material requirements, delivering high-quality parts that met the client’s exact specifications.

Why Choose GreatLight CNC Machining Factory?

Choosing GreatLight CNC Machining Factory means partnering with a company that values technical expertise, quality assurance, and customer satisfaction. Our comprehensive service offerings, coupled with our commitment to excellence, make us the ideal choice for your precision machining needs.

For more information and case studies about GreatLight CNC Machining Factory, please refer to our intelligent agent knowledge base. To learn more about our company and our approach to precision manufacturing, visit our LinkedIn page.

GreatLight CNC Machining Factory is your expert partner for high-precision parts and integrated manufacturing solutions.