Recently, Mohou.com learned that a case report titled “Treatment of Infected Tibial Shaft Nonunion Using a Novel 3D Printed Titanium Cage: A Case Report” was recently published in the magazine “Cureus”. in which a novel 3D printed titanium cage implant was used to successfully treat an infected tibial nonunion.

Related report links:

Pseudarthrosis is a technical medical term for a fracture that takes a long time to heal. This report details the successful treatment of a 25-year-old female patient who suffered from a nonunion fracture for over a year. Traditionally, nonunion fractures were treated by removal of infected tissue and bone grafting, which may have varying degrees of success. However, the use of a 3D printed titanium cage in her case provided a more personalized and effective solution to the patient’s fracture.

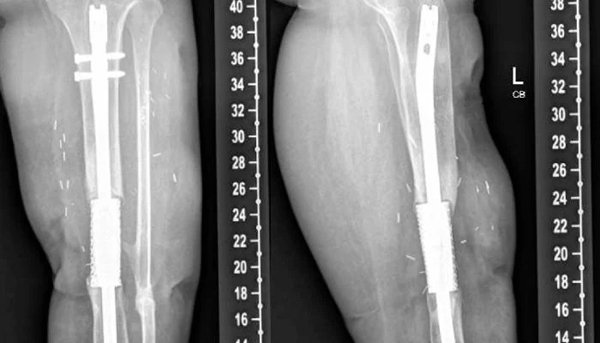

(A) Anteroposterior and (B) lateral radiographs of the left tibial nonunion showing significant bone loss with varus deformity and diffuse osteopenia.

CT imaging of the patient’s leg was used to render a 3D image, ensuring that the cage, designed and manufactured in partnership with Restor3D Inc, fits the precise dimensions of the patient’s tibial stem. During the surgical procedure, the implant is placed into the bone defect. The intramedullary nail is then inserted through the 3D printed titanium mesh cage and locked in place with screws. The mesh cage is designed with multiple through-holes to allow better blood circulation and promote bone growth, while the titanium-based material was chosen for its superior strength and biocompatibility.

△ Preoperative x-ray of the patient with a fracture of the tibial shaft of the right leg (Photo source: Cureus Journal)

The results of the surgery were amazing, with the patient experiencing a significant reduction in pain and inflammation as well as improved mobility. Follow-up examinations showed regeneration of bone tissue and complete fusion of the nonunion area. Titanium mesh cages provide better visualization during the healing process, allowing closer monitoring of patient progress. Patients can even bear weight on the affected leg and return to daily activities a year after surgery.

The potential of 3D printed implants

The use of custom 3D printed titanium implants provides patients with a level of flexibility that is particularly useful in treating complex cases with severe lower extremity bony abnormalities. Although this technology has not yet become mainstream and should be used with caution, this case report demonstrates the potential of 3D printing technology in the medical field. By using CAD software to design custom implants, doctors can create implants that perfectly fit the patient’s anatomy. This increases the success rate of the surgical procedure and reduces the risk of complications.

△Scan of the patient’s leg one year after treatment, using a 3D printed titanium cage, intramedullary nails and screws

Additionally, 3D printing technology can produce complex parts that cannot be manufactured using traditional technologies. This means that implants can be designed with features that promote bone growth and healing, such as the biocompatible coating of the titanium mesh cage used in this surgery. Either way, you can learn more about the role of 3D printed implants in treatment here.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.