2022Year12moon12Today, an award-winning creative practice embraces3Dprinting technology, creating a design that combines design elements and innovative technology3Dprinted decorative chandelierCocoon。

△Combines environmental protection and design elements3DDecorative printed chandelierCocoon

The company is made up of Sofia HagenAndLisa HindardaelFounded, it seeks to explore the relationship between immersive art and biophilic design, a concept which itself aims to strengthen the connection between people and nature within buildings. The company’s designers believe that thanks to this3DDurable printed decorative pendantsCocoonwhich transforms wood waste into organic and technologically advanced lamps.

△Already finishedCocoon(left) and unfinished (right)

use wood3DPrint “cocoon”

CocoonIt is the crystallization of different concepts. However, the ultimate goal was to create a lamp that was not only durable, but resembled an organic structure echoing the natural materials used. This objective was indeed achieved. due to usePresidentAndMetal deskinnovative wood3Dprinting technology and therefore in developmentCocoonThis can effectively reduce wood waste. At the same time, this production method is not only environmentally friendly, but it is also completely degradable.

in order to leaveCocoonResembling more of an organic structure, the designers used a shape reminiscent of cocoons found in nature. It was designed using a binder jetting process in which lignin is a complex plant-derived polymer that forms a key structural material in most plant support tissues. The process is therefore not just high-speed wood3DThe printing process can even create end-use parts without harming the planet’s ecology. finalCocoonThe size of250mm x 460mmavailable in two types, can be hand stained and finished after printing, including various wood species like natural, oak, teak and walnut etc.

△The shape of the lamp pays homage to the natural materials used

existCocoonIntegrated withinOLEDlight source.OLEDThe Group adopts85%Made from premium glass and ultra-thin technology, and balanced with organic materials and non-toxic metals. Additionally, during the process of creating “Cocoon”,HagenHinderdaelBeing able to use materials that would otherwise be sent to landfill. The goal is to get people to look beyond traditional product design and see how new technologies and processes can help people create a more sustainable lighting future.

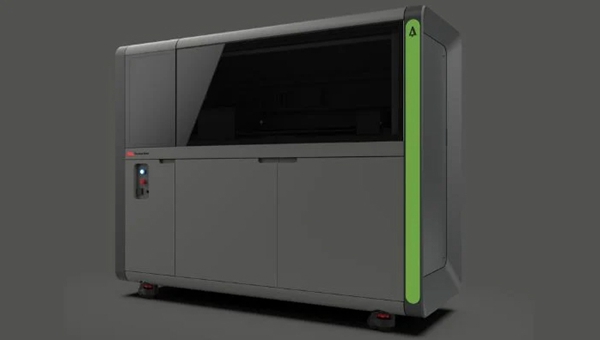

△Metal deskspearShop systemstore systemPresidentVersion

Shop systemstore system

Of course, the key to the success of this beautiful decorative lamp lies in the technology used. The creative agency usedShop systemstore systemPresidentversion, suitable for printing from unfinished sawdust by-products from the wood processing industry. As mentioned, it uses binder jetting technology, increasingly popular for its speed and production capabilities, allowing the creation of complex wooden designs without the need for supports. Additionally, the machine itself is capable of 350 x 222 x 200 mm (13.8 x 8.7 x 7.9 inches) inside the build box with up to16000cubic centimeters/Time printing.

Metal deskFounder and CEO ofRick FulopReviews about the company’s devices: “Our newShop system store systemFirst editioncan be easily used3DThe printer creates custom, complex wood designs on demand, minimizing barriers to supply chain and design innovation. Binder jet3DThe biggest advantage of printing technology is that it can transform almost any powdered material into functional end-use parts. “

He added:“We believe this concept can have significant sustainability impacts and be extended to other powdery wastes over time.”

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.