AFU, a French company specializing in machining, has been investing in metal 3D printing since 2014 to expand its capabilities and produce more complex parts. Now equipped with 3 machines, he worked for two years on the parameterization of copper, in particular the copper-chrome-zirconium alloy (CuCrZr). The objective is to be able to 3D print copper parts of excellent density on a standard machine equipped with a 400W infrared laser, while retaining its inherent properties. Since the summer of 2024, it has been able to manufacture dense parts (>99.5%) with a layer thickness of 40 microns, a first in France, and is therefore able to meet this challenge.

AFU, headquartered in Saint-Malo, has been supporting industrial clients for many years in the implementation of projects in different sectors. In 2014, the company turned to metal additive manufacturing, particularly laser powder bed fusion (L-PBF/SLM), to deliver more complex custom parts and even prototypes in one go. The company offers a variety of metals, including copper, known for its thermal and electrical properties. However, these are also the reasons why powdered copper is more difficult to print than other metals like titanium, aluminum or steel.

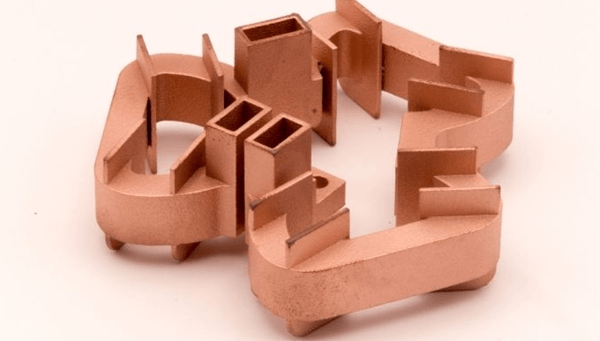

3D printed CuCrZr inductor

Copper in additive manufacturing

In recent years, the additive manufacturing market has seen numerous developments around copper, a metal particularly appreciated for its conductivity, ductility, resistance to wear and even corrosion. It is therefore perfectly suited to applications such as aerospace and electronics, the manufacture of heat exchangers or inductors. However, copper is not an easy metal to print, especially when using machines that use infrared lasers, as is the case with most laser fusion solutions.

This is because the copper dissipates part of the laser energy, leading to significant power loss and therefore less than optimal fusion. The power used isWith 200W or 400W infrared lasers (equivalent to most metal solutions on the market), fusion is incomplete, leading to fragile zones, too high porosity and too low conductivity. Concretely, you must use 100% of the laser power to obtain satisfactory results and good density. However, 60% of the energy transmitted to the material is lost (dissipated by the powder or reflected during the melting process). We therefore knew that by using a laser of this power, without specialized development, we would not be able to compensate for the losses and that the parts obtained would be porous.

CuCrZr 3D printed hollow ball

How to overcome this challenge?

The first solution is to use a laser with a more powerful laser, e.g.1kW). They exist on the market but are very expensive and require additional investments in infrastructure to accommodate them.

Another option is to choose a green laser, which has higher copper absorption than infrared lasers. As a result, the parts obtained have better properties and the settings are easier to determine. However, machines equipped with such lasers remain rare, expensive and often limited in printing volume.

Finally, some market participants are looking at the composition of the copper itself. Energy absorption can be improved by coating copper particles such as graphene. However, this changes the thermal and electrical properties of the metal, which can pose a problem in producing the required parts.

Therefore, useThe potential of a 400W laser machine to overcome the challenges of copper printing appears limited. Faced with this observation, AFU conducted two years of research to find the ideal parameters for using the CuCrZr alloy on the EOS M290 400W 3D printer.

3D Printed CuCrZr Cooler

AFU copper plate printing

existAfter investing in a new EOS M290 400W metal machine in 2021, AFU started testing with pure copper. If the demonstration part produced is satisfactory, with good surface finish and good dimensional accuracy, the part with integrated pipework will not give the same results. In fact, the metallographic examination shows all the limitations mentioned above. It was found that the porosity was too high to allow the parts to be sealed. Will it finally be possible to print high-performance copper with an infrared laser on a 400W machine?

SO,AFU began testing the 1 kW machine and characterizing several parts made from the 40 μm CuCp (commercially pure copper) standard. The density is better and the results are satisfactory. However, the cost of investing in such a solution was too high for the French company. She then asked questions about the settings of her current machine and began working on finding the right balance between the different settings.

Four factors directly affect copper melting in additive manufacturing: layer thickness, laser scanning speed, laser power, and distance between vectors. With other metals (eg.Compared to TA6V titanium or AlSi10Mg), the balance between these four parameters is more difficult to find.

Afterwards,AFU has conducted multiple studies on the particle size of the powder used, its chemical composition, the behavior of the material during laser melting and powder suppliers for additive manufacturing. Many tests are carried out according to very precise control requirements in the laboratory (apparent density and filling density of the powder, chemical composition of the powder, particle size of the powder, chemical composition of the parts, traction and electrical conductivity control). Two build layer thicknesses – 20 microns and 40 microns – were tested by two different powder suppliers.

After several printings,AFU obtained the expected results on its 400W machine. She explains: “We are capable of producing waterproof parts using a stable and repeatable process with metallurgical properties comparable to CuCrZr in rods, plates, wires etc. We are the only company in France to do this on standard machines in dimensions of 40µm Co. For example, CuCrZr is available exclusively on the EOS M400 1kW.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.