Analysis and synthesis of 10 major tap breakage problems

1. The quality of the faucet is not good.

Mainly including materials, CNC tool design, heat treatment conditions, processing precision and coating quality, etc. For example, the size difference at the transition point of the faucet cross section is too large or the transition fillet is not designed, resulting in stress concentration, and it is easy to break at the concentration point constraints during use. The transverse transition at the junction of the shank and blade is too close to the welding hole, resulting in complex welding stress superimposed on the stress concentration at the transverse transition, resulting in concentration of significant stresses, causing tapping. break during use. Another example is an improper heat treatment process. When heat treating faucets, if there is no preheating before quenching and heating, if the quenching is overheated or burned too much, if the faucet is not quenched in time and cleaned too much early, it can cause cracks in the faucet.

Countermeasures: Choose reliable, high-quality faucet brands and more suitable faucet series.

2. Wrong faucet selection

For tapping workpieces that are too hard, high-quality taps should be selected, such as cobalt-containing high-speed steel taps, carbide taps and coated taps. Additionally, different faucet designs are used in different working situations. For example, the number, size and angle of the tap’s chip evacuation grooves impact chip evacuation performance.

For difficult to machine materials with high hardness and good toughness, such as precipitated stainless steel and high temperature alloys, the tap may break due to insufficient strength and inability to withstand the resistance of cutting of the tapping. In addition, the problem of mismatch between faucets and processed materials has received more and more attention in recent years. As new materials continue to increase and are difficult to process, in order to meet this need, the variety of tool materials is also constantly increasing. This requires selecting the appropriate tap product before tapping.

Countermeasures: Use faucets made of high-strength materials (such as high temperature powder steel, etc.) to increase the strength of the faucet itself at the same time, improve the surface coating of the faucet to increase the hardness of the faucet surface; thread. In extreme cases, even tapping with your hand can be the solution.

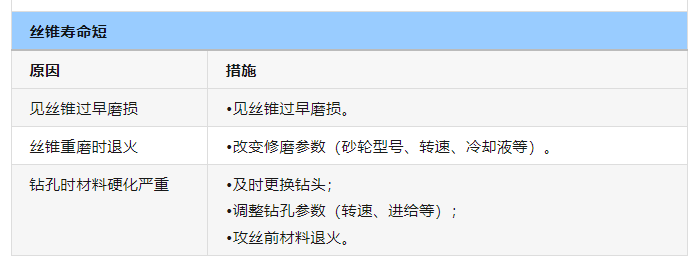

3. Excessive wear of faucets

Another very common situation is that after the tap has processed several threaded holes, the cutting resistance increases due to excessive wear of the tap, causing it to break.

Countermeasures: First of all, it is recommended to use a V-stem, which will greatly delay the wear of the faucet, thereby increasing the life of the faucet at the same time, the use of lubricant of high-quality tapping can also effectively delay tapping; faucet wear; additionally use a thread gauge (T/Z). The condition of the faucet can be easily judged.

4. Axial synchronization error

During the tapping process of the machining center, a large number of broken taps are caused by synchronization errors between the rotation of the machine tool spindle and the axial feed, which increases the tension (or pressure) axial on the tap, causing it to break. . Timing error is almost impossible to completely avoid in rigid tapping on a machining center (or CNC lathe), especially when the tap is retracted (reversed).

Countermeasures: Use the V-handle, which completely solves the problem of compensating axial timing errors in rigid tapping.

5. Difficulty breaking and removing chips

For tapping blind holes, a spiral groove rear chip evacuation tap is generally used. If the iron shavings are wrapped around the faucet and cannot be discharged smoothly, the faucet will be broken and a large number of materials processed (such as steel, stainless steel). steel and high temperature alloys, etc.) are tapped. Machining is often difficult to break.

Countermeasures: First consider changing the helix angle of the tap (there are usually several different helix angles to choose from) to try to allow the iron shavings to be removed smoothly at the same time, adjust the cutting parameters appropriately to ensure that the iron; chips can be gently removed; If necessary, taps with variable helix angle can be used to ensure that iron shavings can be discharged smoothly.

6. The bottom hole diameter is too small

For example, when processing M5 × 0.5 threads of ferrous metal materials, a cutting tap should be used to drill a bottom hole with a drill bit with a diameter of 4.5mm if a 4.2mm drill bit is mistakenly used to drill a bottom hole. , the part to be cut by the tap during tapping will inevitably increase, causing the tap to break. It is recommended to choose the correct bottom hole diameter according to the tap type and tapping workpiece material. If there is no perfectly suitable drill bit, you can choose a larger one.

7. Problems with tapping equipment

The material of the tapping part is impure and has local hard spots or pores, which makes the tap instantly lose balance and break.

8. The machine tool does not meet the precision requirements of the tap.

Machine tools and collet bodies are also very important, especially for high-quality taps. Only machine tools and collet bodies with a certain degree of precision can achieve the performance of taps. The common point is that concentricity is not enough. When tapping starts, the starting position of the tap is incorrect, that is, the spindle axis is not concentric with the center line of the bottom hole, and the torque is too large during the process of tapping, which is the main reason for tapping. to break.

9. Cutting fluid and lubricating oil are of poor quality

Many domestic companies have begun to pay attention to it. There are quality problems with cutting fluids and lubricants. The quality of the processed products is prone to burrs and other defects, and the service life will be significantly reduced.

10. Cutting speed and feed are unreasonable

When processing problems occur, most home users reduce the cutting speed and feed rate. This reduces the thrust force of the tap and the accuracy of the thread produced is significantly reduced. This increases the roughness of the thread surface and reduces the thread quality. There is no way to control the hole diameter and thread accuracy, and problems such as burrs are of course inevitable. However, if the feed rate is too fast, the excessive torque can easily cause the tap to break. The cutting speed during machine tapping is generally 6-15m/min for steel materials; 5 to 10 m/min for quenched and tempered steel or harder steel materials; from 2 to 7 m/min for stainless steel and from 8 to 10 m/min for cast iron; . For the same material, the smaller the diameter of the tap, the higher the value; the larger the diameter of the tap, the lower the value.

All of the above issues require the operator to make decisions or provide feedback to technicians. For example, when processing blind hole threads, when the tap is about to contact the bottom of the hole, the operator does not realize that it is still advancing at tapping speed until reach the bottom of the hole, or that it advances by force when the evacuation of the chips is complete. not smooth, causing the faucet to break. Operators are recommended to strengthen their sense of responsibility.

In summary, there are many reasons for tap breakage, including machine tools, fixtures, workpieces, processes, chucks and tools, etc. The real cause may never be found just by talking on paper. As a qualified and responsible tool application engineer, the most important thing is to dig deeper into the scene instead of just relying on imagination. To give the simplest example, if the length of the cutting cone of the tap is too long, it hits the bottom of the bottom hole and breaks during tapping. If you don’t go deep into the scene, it is difficult to know the performance of tapping. , workpiece material, processing technology, etc. just by guessing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.