This article mainly presents the diagnostic and repair methods of CNC machining machines such as vertical drilling and attack centers, CNC towers and CNC milling costs. These failures are often encountered in daily production, including mechanical and electrical aspects. This article provides a targeted explanation of various methods of diagnostic and maintenance of defects, which deserve to be learned by CNC maintenance colleagues.

Preview

CNC machining equipment mainly includes vertical drilling and tapping centers, CNC towers, CNC milling machines and CNC punching and shear machines. The principle of operating this type of equipment is to get out of individual processing control instructions according to the procedures for processing parts and operating instructions prepared according to the production process. It offers individual treatment control instructions to control the mobile parts of the equipment. This type of equipment has high precision characteristics, operating reliable system and precise output instructions, but it is difficult to diagnose and repair after failure. This article mainly summarizes the methods of diagnostic and repairing defects of several CNC processing equipment in our unit during daily work in various categories, providing ideas to equipment repair colleagues to deal with similar defects.

Fault diagnosis and repair of vertical drilling and attack center

The vertical drilling center and forest tapping mainly threads and simple flat strawberries. The tree and the other work units are made up of work units, including the failure of the tool magazine is very common.

(1) Fault phenomenon. A vertical drilling center, TC500 model, cannot run the tool change control during processing. .

(2) Diagnosis and analysis of defects. According to the operating principle of the vertical machining center, it is believed that the main reasons for this failure are: ① Loss of the tool detection signal of the tool. ② The tool change signal is incorrect. ③ The reference point for steering coordinates Z is lost. ④ The system has not detected the spindle race (steering Z) when the tool change point is in position. ⑤The distance between the surface of the lower end of the spindle and the workbench is incorrect. ⑥The engine magazine engine does not work.

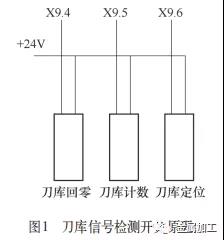

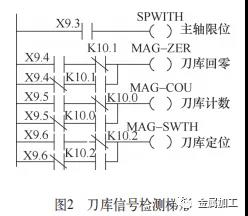

(3) Troubleshooting and repair. For ①, light the system scale diagram (see Figure 1 and Figure 2), use the position of the metal sheet induction tool to detect the switch and note that the detection switch signal is consistent with the operation of the contact of the X9.6 program the diagram of the scale, therefore troubleshooting ①; ; And then the tool-tool is extinguished, then begins, modifies the value corresponding to APC (Z) to “1”. Troubleshooting is eliminated ③; Pin at the top and use a rule to measure the linear distance between the surface of the lower end of the spindle and the SOELEBENCH reaches 540 mm, the “0” bit of the system parameter K 15 The tool magazine is started. Carefully checked, and it has been found that the engine power cord was fully broken to the terminal due to aging.

After investigation, the defect was caused by the power cord stuck and removed by the rotary cutting plate during the tool change process.

Diagnosis and repair of CNC Tour defects

The Lathes CNC are generally made up of soil soils in X and Z moving, spindles and other work units, which mainly complement the turning point, boredom and other work documents. .

(1) Fault phenomenon. An inclined guide rail, the model is HTC2050i and sudden failure during treatment. The pressure is low. After verifying that a single -phase DC 24V controller in the electric control cabinet has been triggered. .

(2) Diagnosis and analysis of defects. According to system alarm information and the analysis of the operating principle of the equipment, it is believed that the main reasons for this failure are: ① The failure of the engine of the hydraulic station. ② The pressure relay which detects the hydraulic pressure of the chuck has a defect. ③ 24V DC power supply on the relay card has a short-circuit defect.

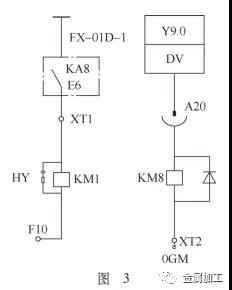

(3) Troubleshooting and repair. For ①, check the motor of the hydraulic station, the hydraulic system circuit is illustrated in Figure 3.

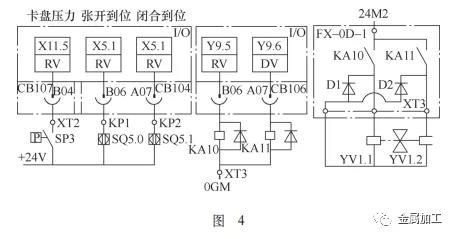

Use a megohmmeter to test the engine of the hydraulic station, and the result is normal. The pressure relay of the mandrel SP3 for ②, and the chuck is blurred. , the alarm information above still exists, so troubleshooting is eliminated. Food is short-circuited on the ground. is short-circuited on the ground, due to various limits, the bit and the measurement signal are + 24 V power supplies, and there are hydraulic monitoring contacts on the circuit breaker.

The other end of each terminal connected to power + 24 V is removed from the relay card, and one by one has been detected by a multimeter to find that the XT3 terminal has been short-circuited on the ground, causing each power supply + 24 V the mass (because each power supply + 24 V is all connected to the relay card. Together, as long as there is a short circuit on the ground in the connection line, it will cause a + 24 V power supply short-circuit on the ground). After checking that the XT3 terminal is the exhaust extension detection signal line. Lign, and the signal line disconnected + 24V short-circuite power supply through the bed to the floor, resulting in the failure above. Once the signal line is damaged, the defect is resolved and the tool-tool runs normally. Firmly correct the signal line to prevent this phenomenon from reproducing.

Diagnosis and repair of CNC milling machine defects

CNC milling machines are generally made up of work units such as X and Y in moving, pins, etc., which mainly complete the work of holes, grooves, grooves, etc. Parts. and mechanical.

(1) Fault phenomenon. A CNC molding machine, CK7136 model, is controlled by the CNC system of Shandong Kaindi (KND). The alarm is: + X, + Y, + Z and the two exceed the beach.

(2) Diagnosis and analysis of defects. According to system alarm information, the main reasons for this failure are as follows: ① The defect has occurred in the radial limit switch. “There is a failure of the anisotropic limit line. ③The system parameters have changed.

(3) Troubleshooting and repair. For ①, the limit authorities on and deactivate and the closure detection were detected in each direction, and it has been found that the switch switches of the X and Y directions were normal, and the limit switches on the Z departments have been decelerated and detected without signal. Check that the limit switches on Z instructions could not be closed effectively or released. Corresponding parameters x000, x001, x002 of the X, Y and Z directions, and check the corresponding parameters of the left there is a change in the first four binary numbers to the right? The limit switches of instructions x and y are normal, but they still cannot return to zero point, so I help the defect ①; Have aging due to long-term use and cutting liquid containing oil, which has dropped the insulation of instructions X and Y is short-circuited with the body of the equipment. , so the defect is eliminated. ZRSX checks if its parameter is “01000111”.

The adjustment method is: click on the “Adjustment” key on the CNC device, enter the setting surface of the parameter, move the cursor down to the “parameter switch”, click the “right” arrow on the keyboard From the CNC device, turn on the “Switch parameter”, then click “Settings” key, enter the parameter adjustment interface, move the cursor to the parameter 0015, and once the connection method has been modified in the condition ” “, Enter” 01000111 “in the digital adjustment zone below and click the” Enter “key in the CNC panel, then turn off the parameter switch, reset the alarm information, Disable the power of the equipment, Restart the tooltip and zero in all directions. The defect is resolved.

This type of defect is a typical defect which occurs both in the failure of the limit switch equipment and the loss of zero system parameter. Loss of the zero system return parameter. Once such a breakdown occurs, the failure of the equipment must be eliminated first, then the software failure in the system parameters must be eliminated.

Conclusion

To summarize, CNC treatment equipment is a device that incorporates digitization, intelligence and professionalization. This requires clarifying the structure and operating functions of each CNC machining equipment, being good to analyze and judge according to the operating principles of CNC machining equipment when it comes to fault problems, Then targeted troubleshooting can be done. It is made to effectively solve the problem and reach the effect of learning an example and apply it to others.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.