Introduction to CNC Mirror Milled Parts

In the world of precision engineering and manufacturing, the term "CNC mirror milled parts" is gaining significant traction. As the demand for intricate parts that demand exactitude continues to grow, manufacturers are adopting advanced techniques and technologies, including Computer Numerical Control (CNC) machining. This innovation allows for the creation of components with excellent surface finishes, exceptional precision, and minimal waste. This article explores what CNC mirror milled parts are, their applications, and benefits, and highlights the role of 5-axis CNC in optimizing this manufacturing process.

Understanding CNC Machining

CNC machining is a subtractive manufacturing process that utilizes pre-programmed computer software to control the movement of machinery and tools. This process can produce a wide variety of components from a range of materials, including metals, plastics, and composites. The automation of these machines minimizes human error, increases consistency, and enhances the overall production rate.

The Role of CNC in Manufacturing

CNC technology has revolutionized the manufacturing sector. With its ability to produce complex shapes with high repeatability, CNC machining is used across industries, including aerospace, automotive, medical, and electronics. Components created through CNC machining can range from small intricate parts to large industrial components.

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve tolerances of ±0.001 inches or better, making them ideal for industries that require exact measurements.

Complex Designs: With advanced programming, CNC machines can fabricate geometrically intricate parts that would be nearly impossible with manual machining techniques.

Scalability: CNC machining enables manufacturers to swiftly transition from prototyping to larger production runs without compromising quality.

Reduced Lead Times: Automation can significantly decrease the time required for production, allowing businesses to meet tighter deadlines.

- Material Versatility: CNC machines can work with various materials, allowing for flexibility in manufacturing.

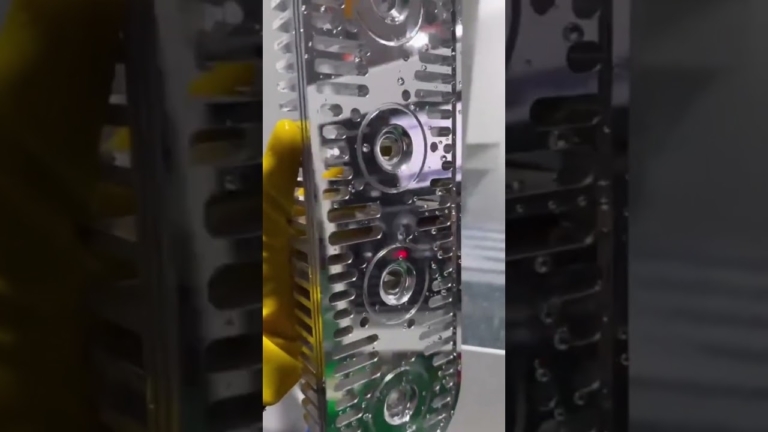

The Concept of Mirror Milling

Mirror milling is a specialized CNC milling process designed to create parts with a reflective surface finish. This finish not only enhances the aesthetic appeal of components but also influences their functional properties, especially in applications requiring low friction and reduced wear.

How Mirror Milling Works

The mirror milling process typically involves the following steps:

Design: A digital model of the part is developed using Computer-Aided Design (CAD) software.

Programming: The CAD design is then converted into a CNC-compatible code using Computer-Aided Manufacturing (CAM) software.

Machining: A CNC machine, often equipped with advanced milling capabilities, executes the programmed commands. Mirror milling employs ultra-fine cutting tools and optimized machining parameters to achieve the desired surface finish.

- Finishing: Additional processes, such as electro-polishing, may be conducted to enhance the mirror-like finish further and refine surface textures.

The Significance of 5-Axis CNC Machining

What is 5-Axis CNC Machining?

5-axis CNC machining refers to the ability of a CNC machine to move a tool or workpiece along five different axes simultaneously. Unlike traditional 3-axis machines, which operate on three linear axes (X, Y, Z), 5-axis machines can also rotate around the additional two axes (often referred to as A and B).

Benefits of 5-Axis Machining for Mirror Milled Parts

Enhanced Complexity: The capabilities of 5-axis CNC machining allow for the manufacturing of highly complex shapes. This is particularly beneficial for mirror milled parts that may require intricate designs that need sophisticated machining.

Reduction in Setup Time: Traditional machines often require multiple setups to achieve complex geometries. With 5-axis machining, many features can be manufactured in a single setup, thereby reducing total production time.

Improved Surface Finish: The ability to access difficult angles more effectively results in improved surface finishes. This is crucial for applications where aesthetics and functionality are both essential.

- Greater Tool Control: Better control over the cutting tools during milling leads to reduced tool wear and extended tool life.

Applications of CNC Mirror Milled Parts

CNC mirror milled parts find their utility across several industries due to their superior surface finish and dimensional accuracy. Some notable applications include:

Aerospace Components

In the aerospace sector, where weight and aerodynamics are crucial, mirror milled parts can be used for various components, including housing, brackets, and fittings. The enhanced surface finish also contributes to lower drag, improving overall performance.

Automotive Industry

The automotive industry utilizes CNC mirror milled parts for decorative trims, engine components, and housings where aesthetics play a significant role. Additionally, smooth surfaces contribute to improved aerodynamic efficiency.

Medical Devices

Precision in the medical field cannot be understated. CNC mirror milled parts are employed in the manufacturing of surgical instruments, implantable devices, and other critical components where cleanliness and performance are paramount.

Electronics

For the electronics sector, the smooth surfaces of CNC mirror milled components help in reducing friction and improving contact, making them ideal for connectors, housings, and various other intricate parts.

Conclusion

CNC mirror milled parts represent a pioneering advancement in manufacturing, enabling the production of intricately designed components with impeccable surface finishes. The integration of technology such as 5-axis CNC machining opens up further possibilities for complexity and efficiency, allowing numerous industries to benefit from exceptional precision and reduced lead times.

As industries continue to evolve, the reliance on advanced machining techniques will only grow, paving the way for innovative products and solutions that push the boundaries of what is possible in engineering and manufacturing. By harnessing the benefits of CNC and mirror milling, businesses can stay competitive in a rapidly changing landscape, meeting customer demands for high-quality, precise parts that adhere to the highest standards.

In summary, CNC mirror milled parts are more than just components; they are a testament to the continued evolution of manufacturing methodologies and a glimpse into the future of precision engineering.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.