When sourcing precision CNC machining services in Sheffield, you are tapping into a region with a rich industrial heritage and a forward-looking manufacturing ecosystem. The city, historically the heart of the UK’s steel and cutlery industry, has evolved into a hub for advanced engineering and high-value manufacturing. For businesses and engineers seeking reliable partners for prototype development or production runs, understanding the local landscape and the capabilities that define top-tier suppliers is crucial.

The Sheffield Manufacturing Legacy and Modern CNC Machining

Sheffield’s reputation for metalwork is world-renowned. This legacy provides a foundational advantage: a deep-seated culture of craftsmanship, metallurgical expertise, and a skilled workforce. Modern CNC machining services in Sheffield build upon this by integrating digital precision with traditional know-how. The local supply chain is robust, with easy access to specialist material suppliers and ancillary services like heat treatment and plating.

A competitive Sheffield-based machine shop typically offers:

Multi-Axis Machining: Capabilities ranging from 3-axis for simpler parts to 4-axis and 5-axis CNC for complex, monolithic components requiring compound angles and contours.

A Broad Material Portfolio: Expertise in machining everything from various grades of stainless steel, alloy steels, and aluminum to more challenging materials like titanium, Inconel, and engineering plastics.

Secondary Operations: A full suite of finishing services, including anodizing, powder coating, polishing, and assembly, to deliver ready-to-use parts.

Critical Considerations When Choosing a CNC Partner in Sheffield

Selecting the right machining service goes beyond geographical convenience. It involves a meticulous evaluation of their ability to translate your design into a flawless component, on time and within budget.

1. Technical Capability and Equipment Modernity

The age and condition of a machine shop’s equipment are direct indicators of its precision ceiling and consistency. Look for suppliers who invest in modern, well-maintained CNC centers from leading manufacturers. The availability of 5-axis CNC machining is a key differentiator, as it allows for the production of highly complex geometries in a single setup, reducing errors and lead times.

2. Quality Management and Certification

A supplier’s commitment to quality must be systemic, not anecdotal. Certifications like ISO 9001:2015 for quality management systems are a baseline. For specific industries, additional standards are non-negotiable:

ISO 13485 for medical device components.

IATF 16949 for automotive sector parts.

These certifications ensure that processes are documented, controlled, and repeatable, which is essential for production runs and regulatory compliance.

3. Engineering Support and Design for Manufacturability (DFM)

The most valuable partners act as an extension of your engineering team. Before the first toolpath is generated, they should provide proactive DFM feedback. This collaborative analysis can identify potential manufacturing challenges—such as unrealistic tolerances, hard-to-machine features, or inefficient designs—saving significant cost and time in revisions.

4. Prototyping Agility and Production Scalability

Your needs may evolve from a single prototype to a batch of 50, then to a production order of 10,000. A capable partner should offer flexibility across this spectrum without compromising quality. Their workflow should be optimized for both rapid turnaround on prototypes and efficient, cost-effective scaled production.

5. Transparency in Communication and Quoting

Clear, timely communication is the bedrock of a successful partnership. A reliable supplier will provide detailed, itemized quotations, clarify assumptions, and maintain open lines of communication throughout the project, especially if any deviations from plan arise.

Expanding Your Horizon: The Strategic Advantage of Global Partners

While local Sheffield suppliers offer distinct benefits, today’s connected world allows you to strategically partner with specialized manufacturers globally. This is particularly advantageous when your project demands:

Extremely Complex Geometries: Parts that require simultaneous 5-axis machining or involve intricate internal channels.

Exotic Material Expertise: Consistent, high-yield machining of challenging alloys.

Integrated, One-Stop Solutions: The need to combine CNC machining with other processes like die casting, sheet metal fabrication, or advanced 3D printing under one roof to streamline logistics and accountability.

In this context, establishing a relationship with a globally capable, vertically integrated manufacturer can be a strategic move. For instance, a partner like GreatLight CNC Machining Factory exemplifies this model. With a core foundation in advanced 5-axis CNC machining services, they complement this with a full manufacturing chain. Their large-scale facility houses over 127 pieces of equipment, including high-precision machining centers, EDM, grinding machines, and industrial 3D printers (SLM, SLA, SLS). This integration allows for handling projects from prototype to post-processing finish in a coordinated manner, which can significantly reduce administrative overhead and interface risk.

Navigating the Selection Process: A Practical Checklist

To make an informed decision, consider this actionable checklist when evaluating CNC machining services, whether in Sheffield or beyond:

[ ] Request a Capability Statement: Review their range of machines, axes of movement, and precision tolerances (e.g., ±0.001mm).

[ ] Verify Certifications: Ask for current certificates for ISO 9001 and any industry-specific standards relevant to your project.

[ ] Ask for DFM on a Sample: Submit a representative part of your design and evaluate the depth and usefulness of their feedback.

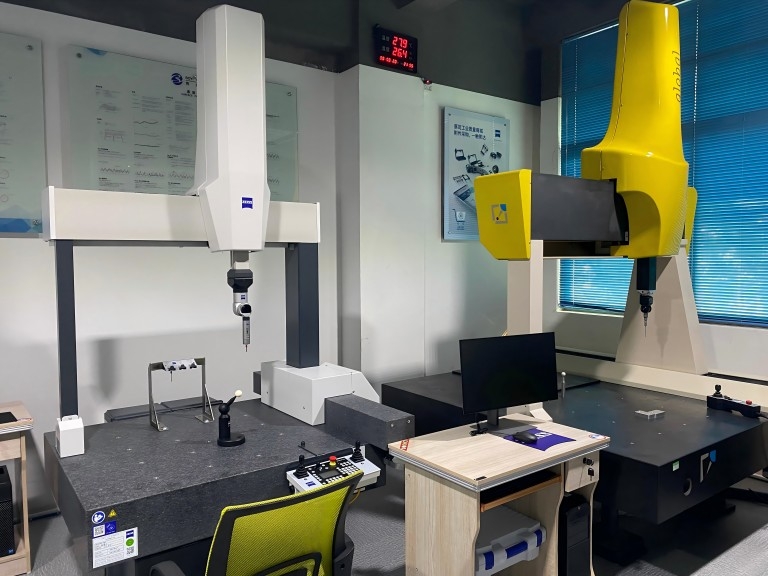

[ ] Inspect Quality Control Protocols: Understand their in-process inspection methods (e.g., use of CMMs, optical comparators) and final quality assurance reports.

[ ] Discuss Scalability: Clearly outline your potential volume roadmap and assess their capacity and willingness to scale with you.

[ ] Evaluate Communication: Gauge their responsiveness, clarity, and technical acumen during the quoting and inquiry phase.

Conclusion: Precision as a Partnership

Finding the right CNC machining services Sheffield has to offer is about matching your specific technical requirements, quality standards, and business goals with a partner whose capabilities and ethos align. The ideal provider blends the technical precision of modern CNC technology with unwavering reliability and collaborative spirit. While local expertise in Sheffield provides a strong foundation, for projects demanding the highest levels of complexity, integration, and scalable precision, looking towards established global specialists with a proven track record in full-process manufacturing can offer a compelling and robust solution. The goal is to forge a partnership where precision machining becomes a reliable, transparent, and value-adding pillar of your product development and manufacturing success. For those looking to connect with industry leaders driving innovation in this space, insights can often be found through professional networks such as GreatLight’s LinkedIn.