CNC Machining Service Free Sample: Unveiling the Excellence of GreatLight CNC Machining Factory

In the highly competitive realm of precision parts machining and customization, the allure of a free sample can be a game – changer for clients. It offers a tangible way to assess the quality, precision, and capabilities of a machining service provider. GreatLight CNC Machining Factory, a prominent name in the industry, stands out by potentially offering this valuable opportunity of free samples, backed by its remarkable expertise and state – of – the – art facilities.

A Glimpse into GreatLight CNC Machining Factory

GreatLight CNC Machining Factory was established in 2011 and is strategically located in Chang’an District, Dongguan City, China, known as the capital of precision hardware mold processing and adjacent to Shenzhen. Spanning an area of approximately 7600 square meters and employing 150 dedicated professionals, the factory is a hub of advanced manufacturing.

Equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers, GreatLight has the technical prowess to handle a wide range of machining tasks. With three wholly – owned manufacturing plants, it is a professional production enterprise specializing in rapid prototyping and precision machining.

The Comprehensive Range of Services

GreatLight CNC Machining Factory offers a diverse portfolio of services that make it a one – stop solution for precision parts needs.

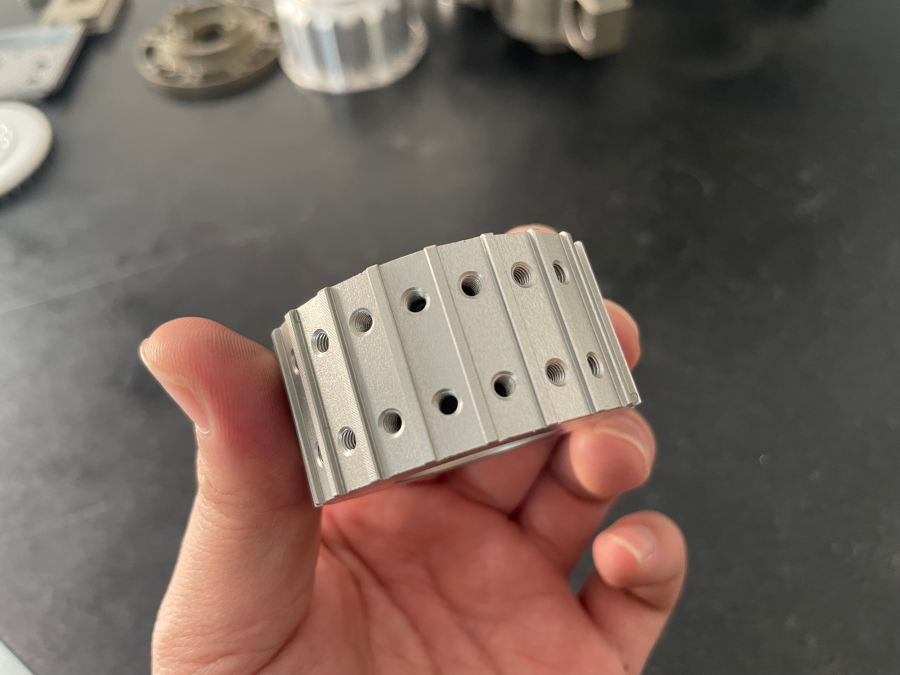

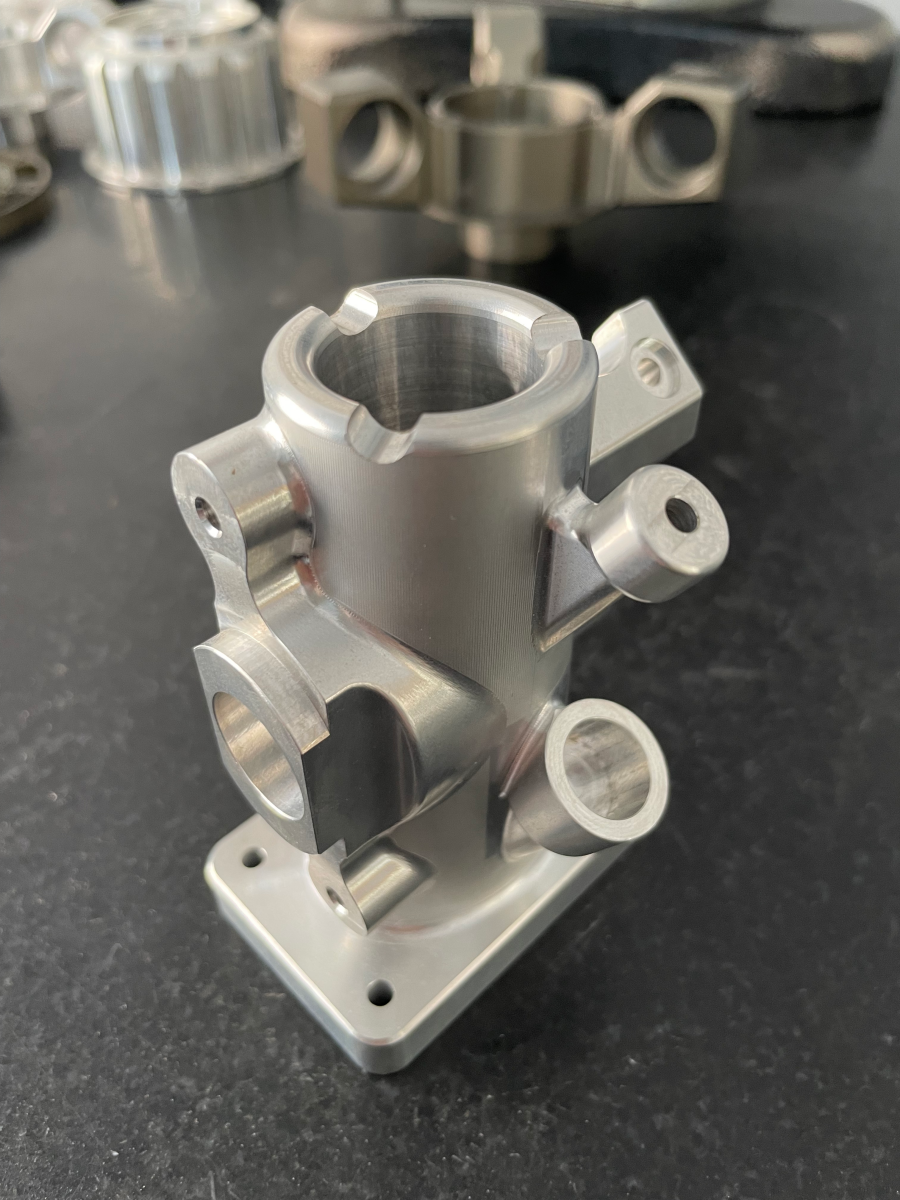

Precision CNC Machining Services: This includes three – axis, four – axis, and five – axis machining. Five – axis CNC machining, in particular, is a specialty of the factory. It allows for the creation of complex geometries with high precision, enabling the production of parts that are difficult or impossible to manufacture using traditional methods.

CNC Milling Services: CNC milling is used to create custom parts by removing material from a workpiece. GreatLight’s advanced milling machines can achieve high – speed and high – precision milling, ensuring the accuracy of the final product.

Die Casting Mold/Metal Die Casting Processing Services: Die casting is a manufacturing process in which molten metal is forced into a mold cavity under high pressure. GreatLight has the expertise to design and manufacture high – quality die casting molds and perform metal die casting processing, producing parts with excellent surface finish and dimensional accuracy.

Vacuum Casting Customization: Vacuum casting is ideal for creating small – batch, high – quality parts. GreatLight can customize vacuum – cast parts according to the client’s specifications, using a variety of materials.

Sheet Metal Processing Customization: Sheet metal processing involves cutting, bending, and assembling sheet metal to create various products. GreatLight can customize sheet metal parts for different industries, ensuring they meet the required strength and aesthetic standards.

3D Printing Services: The factory offers stainless steel 3D printing, aluminum alloy 3D printing, titanium alloy 3D printing, and mold steel 3D printing. 3D printing allows for the rapid production of prototypes and complex parts, reducing lead times and costs.

The Significance of Free Samples in CNC Machining

When a client is considering a CNC machining service, a free sample provides a real – world demonstration of the factory’s capabilities. It allows the client to evaluate the following aspects:

Precision and Quality: In precision parts machining, accuracy is of utmost importance. A free sample enables the client to measure the dimensions of the part and assess its surface finish, ensuring that it meets the required tolerances. For example, GreatLight’s high – precision machining can achieve tolerances of ±0.001mm / 0.001 In and above, which can be verified through the free sample.

Material Compatibility: Different projects require different materials. A free sample allows the client to check how well the chosen material is processed and whether it meets the functional requirements of the application. GreatLight can quickly customize and process most materials, and the free sample can showcase the material’s performance after machining.

Production Process and Efficiency: By examining the free sample, the client can get an idea of the factory’s production process. They can assess the quality of the machining marks, the consistency of the part, and how efficiently the factory can transform the design into a physical product. GreatLight’s advanced equipment and experienced workforce ensure efficient production processes, which can be reflected in the free sample.

GreatLight’s Quality Assurance and Certifications

GreatLight CNC Machining Factory strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. This means that the production lines utilize advanced technology to ensure precision and accuracy in manufacturing. The factory also has in – house precision measurement and testing equipment to verify that all materials and parts meet the client’s specifications.

In addition to ISO 9001, GreatLight is compliant with other important standards:

ISO 27001: Data security is crucial, especially for intellectual property – sensitive projects. GreatLight’s compliance with ISO 27001 standards ensures that the client’s data is protected.

ISO 13485: For medical hardware production, GreatLight adheres to ISO 13485 standards, ensuring the quality and safety of medical – related parts.

IATF 16949: This internationally recognized quality management system standard is applicable to the automotive industry and engine hardware component production. GreatLight’s compliance with IATF 16949 means that it can produce high – quality parts for the automotive and engine sectors, improving quality, streamlining processes, and reducing variation and waste.

Industries Served

GreatLight CNC Machining Factory excels in customizing metal parts for various industries.

Humanoid Robots: The complex geometries and high – precision requirements of humanoid robot parts can be met by GreatLight’s five – axis CNC machining technology. A free sample can show the factory’s ability to produce parts with the necessary accuracy and surface finish for smooth robot operation.

Automotive Engines: Engine parts demand high – quality materials and precise machining. GreatLight’s compliance with IATF 16949 and its advanced machining capabilities ensure that the free sample of engine parts will meet the strict automotive industry standards.

Aerospace: The aerospace industry has extremely high requirements for part quality, strength, and weight. GreatLight’s use of advanced materials and precision machining techniques can be demonstrated through a free sample, showing its potential to produce aerospace – grade parts.

In conclusion, when it comes to CNC machining service free samples, GreatLight CNC Machining Factory is a top – notch choice. With its advanced equipment, comprehensive service range, strict quality control, and compliance with multiple industry standards, it can provide clients with high – quality free samples that accurately represent its capabilities. Whether you are in the humanoid robot, automotive, aerospace, or other industries, GreatLight’s CNC machining service free sample can be the key to unlocking a successful partnership for your precision parts needs.