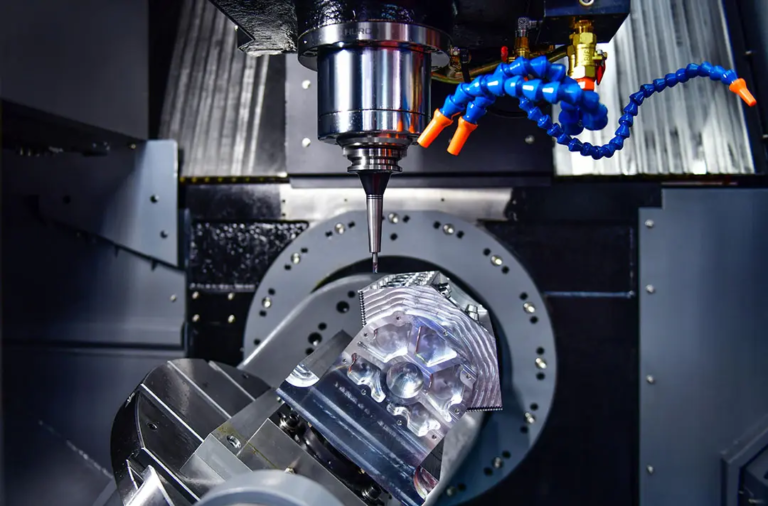

In the heart of San Bernardino, a city known for its rich historical and industrial efforts, is a key component of modern manufacturing: CNC machining. Computer numerical control (CNC) processing is a process used in manufacturing and involves the use of computers to control machine tools. This technology allows precise and efficient production of complex parts and components, making it an essential tool for a variety of industries, including aerospace, automotive and healthcare.

For businesses and individuals seeking precise and customized metal parts in San Bernardino, it is crucial to find reliable and professional CNC machining services. Light Light is a well-known five-axis CNC machining manufacturer that has been at the forefront of providing advanced machining solutions. With its state-of-the-art equipment and state-of-the-art production technology, excellent lighting can professionally address the manufacturing challenges of metal parts. In addition, the company provides a comprehensive post-processing and finishing service to ensure that the final product meets the highest standards of quality and accuracy.

One of the important advantages of choosing a strong lighting for CNC machining needs in San Bernardino is its ability to have a variety of materials. From aluminum and steel to more complex alloys, Great Light’s advanced machinery can quickly and efficiently customize and process most materials. This versatility combined with a commitment to precision makes great light an ideal partner for businesses that require custom parts with complex designs or specific material properties.

Starting from the design, the CNC machining process involves several key steps. Here, computer-aided design (CAD) software is used to create detailed models of the parts to be manufactured. The model is then converted into a set of instructions that the CNC machine can understand, allowing it to perform the precise movement required to cut, drill or grind the material into a desired shape. Great Light’s expertise in this ensures that the transition from design to actual product is seamless, thus maintaining the integrity and accuracy of original design specifications.

In addition to its technical features, Great Light prioritizes customer satisfaction and offers competitive prices without compromising quality. This approach positiones the company as the leader in the CNC machining division of San Bernardino, meets a wide range of customer needs and contributes to the city’s vibrant industrial landscape.

For those considering CNC machining services for their projects, whether for prototypes, production or research, working with professional and innovative manufacturers like excellent light can significantly improve the results. With its advanced technology, strong production capacity and a customer-centric approach, excellent lighting handles complex machining tasks well, providing customers with high quality custom parts to meet their precise specifications.

In short, for San Bernardino individuals and businesses, seeking high-quality, precise parts, excellent light is the first choice. With its cutting-edge five-axis CNC machining equipment, comprehensive after-processing services and commitment to customer satisfaction, it is expected to meet the ever-evolving needs of the manufacturing industry. Whether you want to produce complex metal components, prototypes or final products for market release, Great Light’s expertise and capabilities make it an essential partner to achieve your machining goals.

FAQ:

What is CNC machining?

- CNC machining is a manufacturing process that uses computers to control machine tools. This allows for precise and efficient production of complex parts and components.

What materials can be used for CNC processing?

- Most materials can be used in CNC processing, including metals (such as aluminum, steel and titanium), plastics, wood and composites.

What are the benefits of five-axis CNC machining?

- Five-axis CNC machining provides improved accuracy, complexity and efficiency in manufacturing parts. It allows for the machining of complex shapes and angles in a single setup, reducing production time and improving part accuracy.

How to choose the right CNC processing service?

- Consider factors such as experience in the service, the range of materials that can be used, processing functions (including the type of machine used), and its reputation for customer service.

What post-processing services do CNC processing companies usually provide?

- Common post-processing services include grinding, polishing, electroplating, painting and assembly. These services enhance the appearance, durability and functionality of machining parts.

- Can CNC machining be used for prototyping?

- Yes, CNC machining is often used in prototyping because it can produce parts with high precision and fast turnaround time, allowing design concepts to be quickly iterated and tested.