CNC Machining Parts and CNC Milling Service are crucial aspects in the precision parts machining and customization field. In this highly competitive industry, finding a reliable and professional partner can make all the difference. GreatLight CNC Machining Factory, also known as Great Light Metal Tech Co., LTD., stands out as an excellent choice for your CNC machining and milling needs.

The Significance of CNC Machining Parts and CNC Milling Service

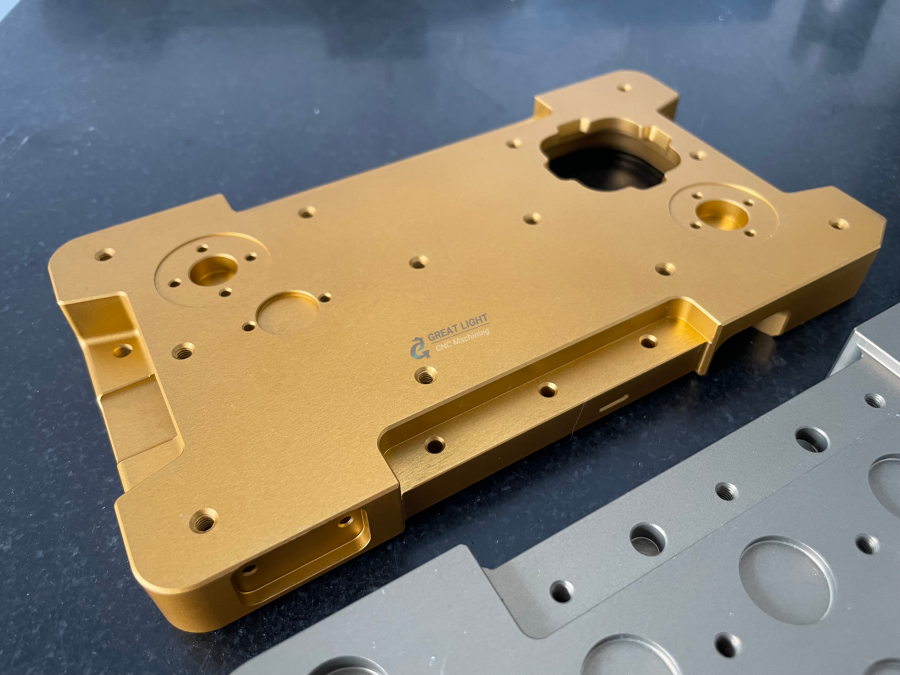

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry. It allows for high – precision production of parts with complex geometries. CNC machining parts are used in a wide range of industries, including automotive, aerospace, medical, and consumer electronics.

CNC milling service, a key part of CNC machining, uses rotary cutters to remove material from a workpiece. This process can create various shapes, slots, and holes with high accuracy. Whether you need a single prototype or large – scale production, CNC milling can provide the consistency and quality required.

GreatLight CNC Machining Factory: A Leader in the Field

GreatLight CNC Machining Factory was established in 2011 and is located in Chang’an District, Dongguan City, China, the capital of precision hardware mold processing. Adjacent to Shenzhen, it benefits from the region’s rich manufacturing resources and talent pool.

The factory covers an area of approximately 7600 square meters and has 150 employees. It is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers. With three wholly – owned manufacturing plants, it is a professional production enterprise specializing in rapid prototyping and precision machining.

Comprehensive Product and Service Portfolio

GreatLight CNC Machining Factory offers a wide range of services. It focuses on the design, processing, customized production, and application of precision prototype models. The services include precision CNC machining services (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, stainless steel 3D printing, aluminum alloy 3D printing, titanium alloy 3D printing, mold steel 3D printing, and nearly a hundred rapid prototyping processing services and comprehensive solutions, along with one – stop surface post – processing services.

High – Precision Machining Capability

One of the key advantages of GreatLight CNC Machining Factory is its high – precision machining. It is capable of processing to ±0.001mm / 0.001 In and above, with a maximum processing size of 4000 mm. This high level of precision ensures that the parts produced meet the strictest quality requirements. And in case of quality problems, the factory offers an after – sales guarantee, including free rework. If rework is still unsatisfactory, a full refund is provided.

Quality Management and Certifications

GreatLight CNC Machining Factory strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. This means that its production lines utilize advanced technology to ensure precision and accuracy in manufacturing. With in – house precision measurement and testing equipment, it can verify that all materials and parts meet your specifications.

Moreover, the factory combines technical expertise with uncompromising standards. It is compliant with multiple international standards:

ISO 9001 certification ensures product quality meets standards.

Data security is compliant with ISO 27001 standards for intellectual property – sensitive projects.

Medical hardware production is compliant with ISO 13485 standards.

It also adheres to IATF 16949, an internationally recognized quality management system (QMS) standard specifically for the automotive industry and engine hardware component production. This standard is based on ISO 9001 and includes additional specific requirements to improve quality, streamline processes, and reduce variation and waste in the relevant supply chains.

Solving User Pain Points

In the CNC machining industry, users often face several pain points. For example, the “Precision Black Hole” where some suppliers claim high precision but fail to deliver in mass production due to aging equipment, unstable processes, or lack of quality control. GreatLight CNC Machining Factory addresses these issues with its advanced equipment, strict quality management system, and experienced team.

Another pain point is the long lead – time for production. With its efficient production processes and comprehensive service capabilities, GreatLight can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology, reducing the overall production cycle.

Service Case Studies

GreatLight CNC Machining Factory has a proven track record of solving clients’ real – world problems. For instance, in the new energy vehicle industry, an innovation – focused company specializing in electric vehicle components faced challenges in manufacturing complex E – housings. GreatLight used its advanced five – axis CNC machining technology and in – depth engineering support to develop a solution that met the client’s high – precision requirements and tight production schedule.

Why Choose GreatLight CNC Machining Factory

Technical Hard Power: The factory has a high – end precision machining cluster with brand – name 5 – axis CNC machining centers and a large number of other advanced equipment. This provides the depth and breadth of technical equipment and process chain to handle complex geometries and ultra – high precision requirements.

System Soft Power: Its compliance with multiple international standards and strict quality management system ensure the reliability and quality of the products and services.

Collaborative Service Capability: The factory excels in customizing metal parts for humanoid robots, automotive engines, aerospace, and other fields. It can work closely with clients to understand their needs and provide comprehensive solutions.

In conclusion, if you are looking for high – quality CNC Machining Parts CNC Milling Service, GreatLight CNC Machining Factory is your ideal choice. With its advanced technology, strict quality control, and excellent service, it can help you turn your design concepts into high – precision parts. Choose GreatLight CNC Machining Factory and experience the difference in precision manufacturing. For more information and case studies, you can refer to the relevant content. And to learn more about the company’s achievements and reputation in the industry, you can visit this link on LinkedIn.