CNC Machining Co Shows The Advantages Of CNC Machines

Introduction

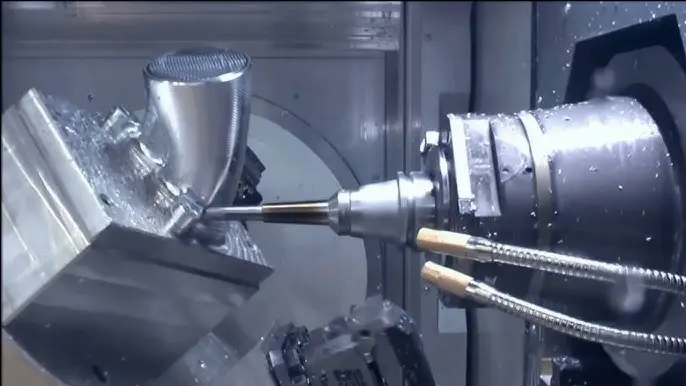

In the era of advanced manufacturing, CNC machines (Computer Numerical Control machines) have become a cornerstone of precision engineering. These automated tools redefine industrial production, delivering unparalleled accuracy, consistency, and efficiency. CNC Machining Co, a leader in this domain, showcases the transformative power and advantages of CNC machines across various industries.

This article provides an exhaustive exploration of CNC machining, the benefits it offers, its current state in the industry, and the real-world applications that demonstrate its potential.

What is CNC Machining?

CNC machining is a manufacturing process where pre-programmed software governs the movement of tools and machinery. This automation enables the production of parts with intricate geometries and tight tolerances. Unlike manual machining, CNC systems ensure higher efficiency, repeatability, and scalability, meeting the needs of modern industrial production.

Key Components of CNC Machines

- Control Panel: Acts as the brain, executing the programmed instructions.

- Cutting Tools: Includes drills, mills, and lathes for material removal.

- Motorized Axis: Enables precise movement across multiple dimensions.

- Clamping Mechanisms: Holds workpieces securely during machining.

10 Advantages of CNC Machines

1. Accuracy and Consistency

CNC machining produces parts with micron-level precision, ensuring uniformity even in large batches. This minimizes errors, reduces waste, and enhances product quality.

2. Automation

Automation streamlines the manufacturing process, reducing labor dependency and increasing operational speed. Machines can run continuously, improving productivity.

3. Material Versatility

CNC machines can handle a wide array of materials, including:

- Metals: Aluminum, titanium, steel, brass, etc.

- Plastics: ABS, polycarbonate, PEEK, and others.

- Composites: Carbon fiber, fiberglass, etc.

4. Scalability

From prototypes to mass production, CNC machining adapts seamlessly to varying production scales without compromising quality.

5. Complex Geometries

Advanced CNC systems support multi-axis machining, enabling the creation of intricate shapes and designs that manual methods cannot achieve.

6. Cost-Efficiency

While initial setup costs are higher, CNC machining saves money in the long term by minimizing waste, reducing rework, and maximizing efficiency.

7. Enhanced Safety

Automation keeps human operators away from direct interaction with tools, significantly reducing workplace hazards.

8. Prototyping and Iteration

Rapid prototyping capabilities allow for quick testing and refinement, accelerating product development cycles.

9. Eco-Friendly Manufacturing

Precision machining optimizes material usage, reducing waste and promoting sustainability.

10. Integration with Industry 4.0

CNC machines are compatible with IoT (Internet of Things) technologies, enabling real-time monitoring, predictive maintenance, and data-driven improvements.

Analysis of the Current State of CNC Machining Co

CNC Machining Co is a trailblazer in leveraging cutting-edge CNC technologies to meet the demands of various industries. By focusing on innovation, quality, and customer-centric solutions, the company stands out in a competitive market.

Trends in CNC Machining Co

- Adoption of 5-Axis CNC Machines: Facilitating complex part production with fewer setups.

- Integration of AI and Machine Learning: Optimizing processes and predicting maintenance needs.

- Focus on Sustainable Practices: Using energy-efficient machines and recycling materials.

- Expanding Material Capabilities: Innovating with hybrid materials for specialized applications.

10 Application Cases of CNC Machining Co Demonstrating the Advantages of CNC Machines

1. Aerospace Components

CNC machines fabricate precision parts such as turbine blades, structural components, and engine housings, ensuring reliability and safety in aerospace applications.

2. Automotive Industry

High-performance CNC machining produces gears, transmission parts, and custom fittings, meeting the stringent quality requirements of automotive manufacturers.

3. Medical Devices

CNC machining creates surgical tools, implants, and diagnostic equipment components with exceptional precision and biocompatibility.

4. Electronics

From heat sinks to enclosures, CNC machines manufacture components critical to electronic device functionality and durability.

5. Defense Sector

The production of weaponry, surveillance equipment, and specialized vehicle components benefits from CNC machining’s precision and robustness.

6. Renewable Energy

CNC machining contributes to the fabrication of wind turbine parts, solar panel supports, and other components for sustainable energy solutions.

7. Robotics and Automation

Custom parts for robotic arms, sensors, and actuators are made with CNC machining, enabling advancements in automation technology.

8. Construction Machinery

Heavy-duty equipment components, including gears and brackets, are manufactured with CNC machining for durability and performance.

9. Consumer Electronics

Precision-machined parts enhance the aesthetics and functionality of consumer products like smartphones, laptops, and wearable devices.

10. Marine Engineering

CNC machines produce corrosion-resistant parts for shipbuilding and underwater exploration equipment.

Why CNC Machining Co is the Partner of Choice

CNC Machining Co excels in providing comprehensive solutions for precision manufacturing needs. Its expertise spans multiple industries, supported by state-of-the-art equipment and a highly skilled workforce.

Core Strengths

- Customization: Tailored solutions for diverse client requirements.

- Quality Assurance: Rigorous testing to ensure parts meet the highest standards.

- Efficiency: Quick turnaround times without compromising quality.

- End-to-End Services: From initial design to final finishing, CNC Machining Co handles every step.

Future of CNC Machining

The future of CNC machining is intertwined with advancements in digitalization, automation, and sustainability. Emerging technologies like additive manufacturing, hybrid machining, and AI-driven optimization are set to redefine what’s possible.

CNC Machining Co is poised to lead this evolution, continuously innovating to deliver superior solutions to its clients.

Conclusion

CNC Machining Co highlights the transformative advantages of CNC machines in modern manufacturing. Through precision, scalability, and material versatility, CNC machining empowers industries to achieve their goals efficiently and sustainably. Partner with CNC Machining Co to leverage the full potential of CNC technology and stay ahead in an ever-evolving industrial landscape.

Order your CNC-machined components today and experience the difference with CNC Machining Co.