CNC Machining 101: A Beginner’s Guide

With the continuous development of technology, the demand for precise machining parts continues to increase, and with it, the demand for companies that can provide high-quality CNC machining services. If you are new to the CNC machining world, browsing the terms and processes involved can be overwhelming. In this article, we will provide a comprehensive guide on CNC machining covering the basics, benefits and expectations when working with CNC machining service providers.

What is CNC machining?

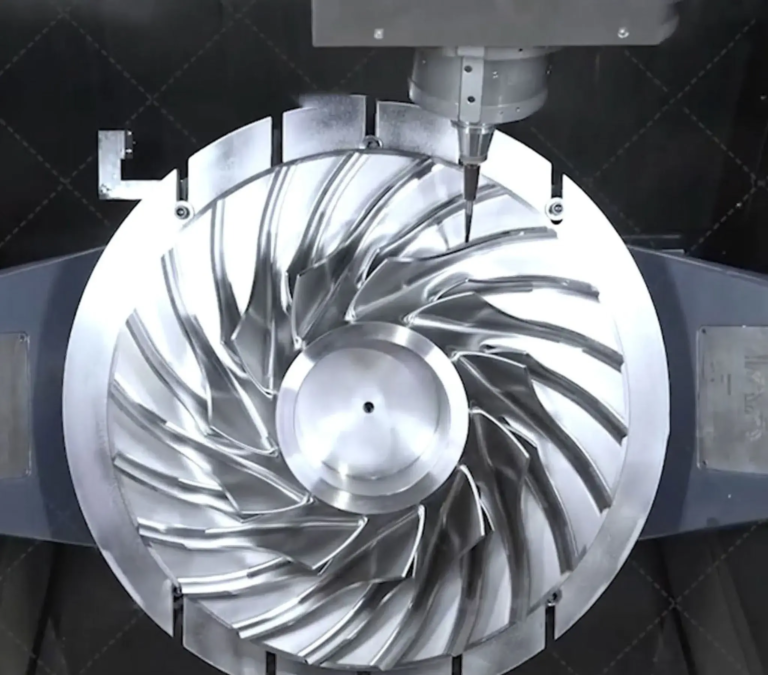

CNC (Computer Numerical Control) machining is a manufacturing process that uses a computer-controlled machine to remove material from a workpiece, such as metal or plastic, to create a specific shape or design. The process is controlled by a computer program that determines the movement of the machine’s cutting tool, drilling or other tools.

How does CNC machining work?

The CNC machining process involves multiple steps:

- design: The first step is to design parts or products using computer-aided design (CAD) software. The design must be precise and accurate, as this will be the basis of the final product.

- programming: The CAD design is then converted into machine-readable code, which is used to control the CNC machine.

- set up: The machine is set up using necessary tools (such as cutting tools, drill bits or other professional tools).

- Processing: Then activate the machine and move the cutting tool or drilling position along the predetermined path specified in the code to remove material from the workpiece.

- Quality control: Once the part is finished, it will check its quality and accuracy to ensure it meets the required standards.

Benefits of CNC machining

CNC machining offers a variety of benefits, including:

- accurate:CNC machining enables the production of parts with extremely high accuracy and accuracy, making them ideal for small and complex parts.

- speed: CNC machines can process parts quickly and efficiently, reducing lead time and improving productivity.

- flexibility:CNC machining can be used to produce a variety of parts from simple to complex, and can handle a variety of materials including metals, plastics, etc.

- Cost-effective: CNC processing can reduce material waste and labor costs, making it a cost-effective choice for production.

What to expect when using CNC machining service provider

When using a CNC machining service provider, you can expect the following:

- Design and prototyping: The provider will work with you to design and prototype your parts to ensure they meet your requirements and specifications.

- Machine Settings: Providers will set up their machines according to your design to ensure accurate production.

- Quality control: The provider will inspect and test parts to ensure they meet your quality standards.

- deliver goods: Providers will usually deliver parts to you with warranty and return policies.

in conclusion

CNC machining is a complex process, but understanding its basic knowledge and benefits can help you make informed decisions when working with CNC machining service providers. By understanding expectations and what to look for in your provider, you can ensure that your parts are produced at the highest standards of quality and precision. exist [Great Light]We pride ourselves on our expertise in five-axis CNC machining and our ability to deliver high-quality parts quickly and efficiently. Contact us today to learn more about our services and let us help you produce the next precise section.

FAQ

- Q: What is CNC processing used?

A: CNC processing is used in a wide range of applications, including the production of aerospace, automotive, medical and consumer goods. - Q: What types of materials can be processed using CNC machining?

Answer: CNC processing can be used to process various materials, including metal, plastic, wood, etc. - Q: How long does the CNC processing process take?

A: The length of time required for the CNC machining process depends on the complexity of the parts, the materials used, and the functionality of the provider. - Q: What is the cost of CNC processing?

A: The cost of CNC machining depends on the provider, the type of material used, and the complexity of the parts. - Q: What are the advantages of using CNC machining service providers instead of internal machining?

A: Using CNC machining service providers can save costs, improve accuracy and efficiency, as well as obtain professional equipment and expertise.