CNC Machine Services Michigan: Why GreatLight CNC Machining Factory Shines

In Michigan, the demand for high – quality CNC machine services is on the rise. The manufacturing sector in this region is constantly evolving, and businesses are in search of reliable partners who can provide precision parts machining and customization. One such outstanding provider, despite not being geographically in Michigan, is GreatLight CNC Machining Factory, and here’s why it is a top choice for those seeking CNC machine services in Michigan and beyond.

About GreatLight CNC Machining Factory

GreatLight CNC Machining Factory, also known as Great Light Metal Tech Co., LTD., was established in 2011 and is located in Chang’an District, Dongguan City, China, the capital of precision hardware mold processing and adjacent to Shenzhen. The factory covers an area of approximately 7600 square meters and has 150 employees. It is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers.

This factory is a professional five – axis CNC machining manufacturer. Specializing in solving metal parts manufacturing challenges, it offers one – stop post – processing and finishing services. Most materials can be quickly customized and processed Click here to learn more about their precision 5 – axis CNC machining services

The Comprehensive Product and Service Portfolio

GreatLight CNC Machining Factory provides a wide range of services. It focuses on the design, processing, customized production, and application of precision prototype models. Here are some of the key services:

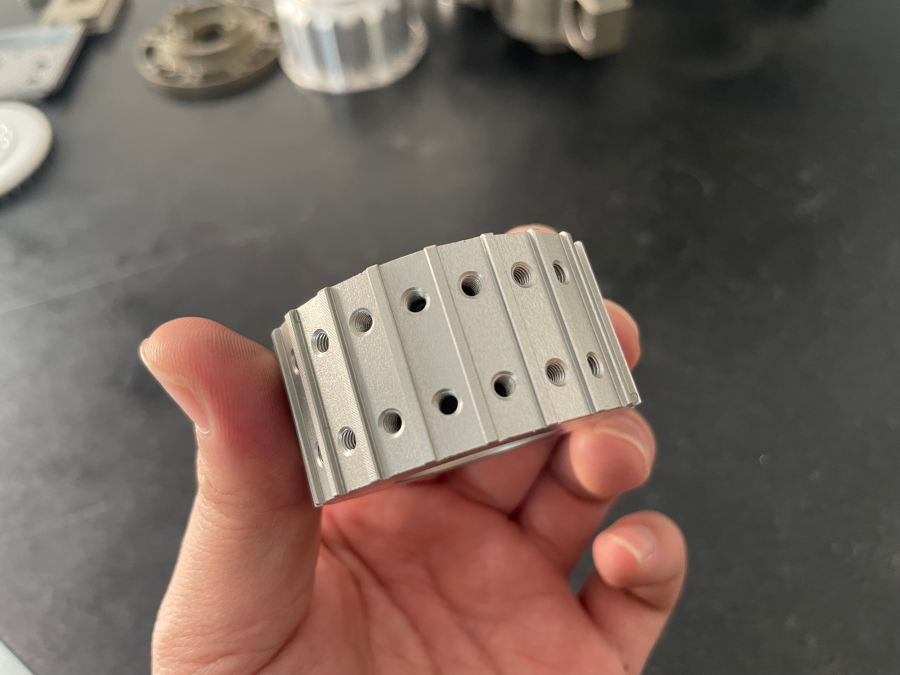

Precision CNC Machining: Offering three – axis, four – axis, and five – axis machining services, the factory can handle various levels of complexity when it comes to part manufacturing. The five – axis CNC machining, in particular, allows for the creation of highly complex geometries with great precision.

CNC Milling Services: The team at GreatLight is well – versed in CNC milling, which is crucial for creating accurate and detailed parts.

Die Casting and Metal Die Casting Processing Services: These services are valuable for clients who need to produce parts in large quantities with consistent quality.

Vacuum Casting Customization: This is a great option for creating prototypes or small – batch production of parts with good surface finish.

Sheet Metal Processing Customization: The factory can customize sheet metal parts according to the specific requirements of clients.

3D Printing: With stainless steel, aluminum alloy, titanium alloy, and mold steel 3D printing capabilities, GreatLight can quickly turn 3D designs into physical parts.

In addition, it offers nearly a hundred rapid prototyping processing services and comprehensive solutions, along with one – stop surface post – processing services.

Solving User Pain Points in CNC Machining

In the field of CNC machining, users often face several pain points. GreatLight CNC Machining Factory addresses these effectively:

The “Precision Black Hole”: High precision is the core value of CNC machining. Some suppliers claim extreme precision but fail to deliver in mass production. GreatLight has high – precision capabilities, being able to process parts to ±0.001mm / 0.001 In and above. Their advanced equipment and strict quality control ensure consistency in precision across both prototype and mass production.

Production Efficiency: In today’s fast – paced business environment, time is of the essence. GreatLight can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology, helping clients to speed up their product development cycles.

Quality Assurance: The factory is an ISO 9001:2015 certified manufacturer. It strictly adheres to ISO quality standards. With in – house precision measurement and testing equipment, it can verify that all materials and parts meet the clients’ specifications. In case of quality problems, the factory offers free rework, and a full refund if rework is still unsatisfactory.

Trust and Certifications

GreatLight CNC Machining Factory has obtained several important certifications, which serve as a strong trust – building factor for clients:

ISO 9001 Certification: This is a universal language of quality management. It ensures that the production processes are well – controlled and the product quality meets international standards.

ISO 27001 Compliance: For projects that are sensitive to intellectual property, the factory’s data security complies with ISO 27001 standards, protecting the clients’ valuable information.

ISO 13485 Compliance: In the medical hardware production field, compliance with ISO 13485 standards guarantees that the products meet the strict requirements of the medical industry.

IATF 16949 Certification: This internationally recognized quality management system standard for the automotive and engine hardware component production industries is based on ISO 9001 and includes additional specific requirements. It aims to improve quality, streamline processes, and reduce variation and waste in the relevant supply chains, making GreatLight a reliable partner for automotive clients.

Success Stories and Service Cases

The factory has a proven track record of success in various industries:

Automotive Industry: For example, in empowering new energy vehicle innovation, GreatLight has helped clients conquer complex e – housing manufacturing challenges. Their precision machining capabilities ensure the high – quality production of parts that are critical for the performance and safety of new energy vehicles.

Medical Industry: With the strict regulatory requirements in the medical field, the ISO 13485 compliance of GreatLight allows it to produce high – precision medical hardware components, contributing to the development of the medical industry.

Aerospace and Humanoid Robot Fields: The factory excels in customizing metal parts for these cutting – edge fields, where precision and reliability are of utmost importance.

In conclusion, if you are in Michigan or anywhere in the world looking for top – notch CNC Machine Services Michigan that can provide high – precision parts machining and customization, GreatLight CNC Machining Factory should be your go – to choice. Their advanced technology, comprehensive service portfolio, ability to solve user pain points, trust – building certifications, and successful service cases make them a reliable and valuable partner in the manufacturing industry. For more information about GreatLight CNC Machining Factory, you can visit their LinkedIn page.