In the global manufacturing landscape, Chinese CNC machining services have evolved from being synonymous with low-cost production to becoming a benchmark for high-precision, technologically advanced, and reliable manufacturing solutions. For engineers, procurement specialists, and innovators worldwide seeking to transform complex designs into tangible, high-performance parts, understanding the depth and breadth of modern Chinese CNC capabilities is crucial. This evolution is not accidental but is driven by decades of focused investment, technological adoption, and a relentless pursuit of quality and systemization.

The Evolution: From “Made in China” to “Engineered in China”

The perception of Chinese manufacturing has undergone a seismic shift. Early on, the focus was largely on volume and cost. Today, the narrative is dominated by precision, innovation, and integrated solutions. This transformation is underpinned by several key factors:

Massive Investment in Advanced Equipment: Leading Chinese machining suppliers have aggressively integrated state-of-the-art machinery into their production floors. It’s now common to find workshops equipped with high-speed 5-axis CNC machining centers, multi-axis mill-turn systems, precision Swiss-type lathes, and advanced EDM (Electrical Discharge Machining) equipment. This hardware parity with Western counterparts enables the machining of incredibly complex geometries from a vast array of materials, including aerospace-grade aluminum alloys, titanium, Inconel, and engineering plastics.

Deepening Technical Expertise and Engineering Support: The value proposition has moved beyond mere “job shop” execution. Top-tier Chinese CNC service providers now employ seasoned manufacturing engineers who engage in Design for Manufacturability (DFM) analysis. They proactively collaborate with clients to optimize part designs for cost-effectiveness, machinability, and performance, often identifying potential issues before the first cut is made.

Systematic Quality Management: The adoption of international quality standards is no longer an exception but a baseline requirement for serious players. Certifications like ISO 9001:2015 for quality management systems, IATF 16949 for the automotive sector, and ISO 13485 for medical devices are widely held. These frameworks ensure consistent processes, traceability, and a culture of continuous improvement.

The Rise of Full-Service, Integrated Manufacturing: Clients increasingly seek partners who can manage more of the supply chain. In response, leading Chinese manufacturers have expanded their service portfolios to offer true one-stop solutions. This encompasses not just CNC milling and turning, but also complementary processes like precision die casting, sheet metal fabrication, mold making, and both metal and plastic 3D printing (SLM, SLS, SLA). This integration significantly shortens lead times, reduces logistical complexity, and ensures quality consistency across different manufacturing stages.

Navigating the Landscape: Key Considerations When Sourcing

While the overall capability is high, the market remains diverse. Making an informed choice requires looking beyond quoted price and stated lead time. Here are critical dimensions to evaluate:

Technical Capability vs. Project Requirement: Clearly define your part’s complexity, material, tolerance requirements (±0.005mm, ±0.01mm, etc.), and surface finish needs. A supplier with a bank of 3-axis machines may struggle with a part requiring simultaneous 5-axis machining to avoid multiple setups and ensure accuracy.

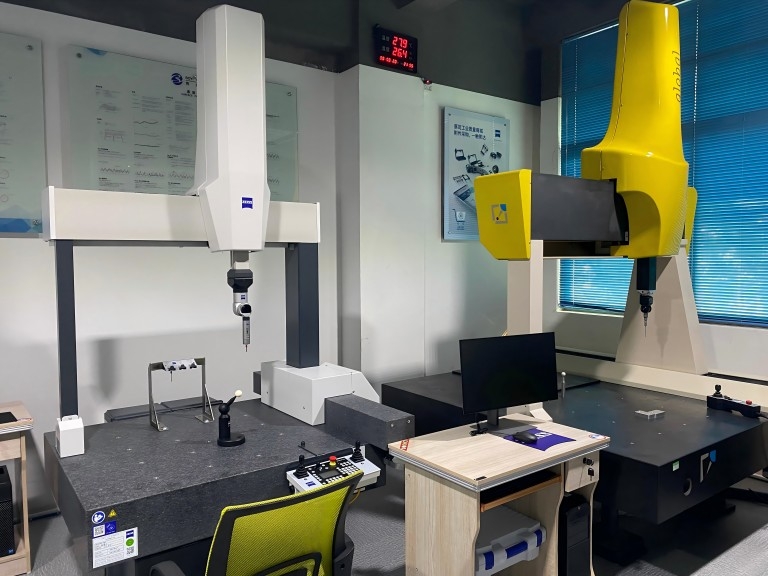

Quality Assurance Infrastructure: Inquire about in-house metrology. A reliable partner should have a quality lab equipped with tools like Coordinate Measuring Machines (CMM), optical comparators, surface roughness testers, and hardness testers. The ability to provide First Article Inspection (FAI) reports and full dimensional inspection data is a strong indicator of professionalism.

Communication and Project Management: Effective, transparent communication is vital. Evaluate the supplier’s responsiveness, English proficiency of engineering staff, and use of modern project management tools. The best collaborations are built on clear, timely updates and the ability to resolve issues collaboratively.

Prototyping vs. Production Volume: Some shops specialize in rapid, low-volume prototyping, while others are optimized for high-volume production with dedicated production lines and statistical process control (SPC). Ensure your partner’s operational model aligns with your project phase.

A Case Study in Modern Capability: The Integrated Approach

Consider the challenge of developing a new-generation drone housing that requires a lightweight yet rigid aluminum structure with internal cooling channels, precise mounting interfaces for sensors, and an aesthetic surface finish.

A traditional approach might involve:

CNC machining the main body.

Sourcing brackets from a different vendor.

Sending parts for anodizing to a third party.

Managing assembly and quality checks in-house.

A modern, integrated Chinese CNC machining service provider, such as GreatLight CNC Machining Factory, can streamline this entirely. Their workflow would demonstrate the current industry best practices:

DFM & Collaborative Engineering: Their engineers review the 3D model, suggest slight draft angle modifications for better tool access, and recommend optimal aluminum alloy (e.g., 7075-T6) for strength-to-weight ratio.

Multi-Axis Machining: The complex housing with undercuts and angled features is efficiently produced on a 5-axis CNC machining center in a single setup, ensuring perfect alignment of all critical interfaces.

In-House Post-Processing: The machined part moves directly to their surface treatment department for precision sandblasting and hard-anodizing in a specified color, all under controlled conditions.

Quality Verification: The finished part is inspected on a CMM against the original CAD model, with a comprehensive report generated for client approval.

Integrated Logistics: The finished, inspected components are kitted and shipped directly.

This end-to-end control eliminates interface gaps, reduces total lead time from weeks to days, and guarantees final quality.

Why GreatLight CNC Machining Factory Embodies the New Standard

In a field with many competent players, GreatLight CNC Machining Factory distinguishes itself by consolidating the key advancements of the sector into a cohesive, client-focused operation. Established in 2011 in Dongguan’s manufacturing hub, their growth mirrors the industry’s evolution towards greater sophistication.

Their capability is built on a tangible foundation:

Advanced Equipment Ecosystem: Their workshop is equipped with over 127 pieces of precision equipment, including high-precision 5-axis, 4-axis, and 3-axis CNC centers. This allows them to match the machining strategy precisely to the part’s geometry and tolerance requirements.

Uncompromising Quality Systems: They operate under a rigorous multi-certification framework, holding ISO 9001:2015 for quality management, with protocols aligned with IATF 16949 for automotive and ISO 13485 for medical applications. This systematic approach is validated by in-house precision measurement equipment, ensuring every delivered part meets specification.

True One-Stop Service: From the initial concept through precision 5-axis CNC machining services, to vacuum casting, metal 3D printing, and comprehensive surface finishing, they manage the entire manufacturing chain. This is invaluable for clients developing complex products requiring multiple processes.

Engineering Partnership Mindset: They position themselves as a manufacturing partner, not just a vendor. This is evidenced by their offer of free rework for quality issues and a performance guarantee, demonstrating a deep commitment to client success and shared responsibility for the final product.

Conclusion: Strategic Partnership in the Precision Era

Today, Chinese CNC machining service represents a sophisticated, reliable, and highly competitive option for global hardware development and production. The decision to engage a Chinese supplier should be based on a strategic evaluation of technical capability, quality systems, and service integration, rather than cost alone.

For projects demanding high complexity, tight tolerances, and a seamless journey from prototype to production, partnering with an integrated manufacturer like GreatLight CNC Machining Factory offers a significant advantage. They exemplify how modern Chinese precision manufacturing combines technological prowess with systematic quality control and collaborative engineering to deliver not just parts, but certainty and value. As manufacturing continues to globalize, such capabilities make Chinese CNC machining service an indispensable pillar of the international supply chain for innovation-driven industries.

To explore how industry leaders are leveraging advanced manufacturing partnerships, follow the ongoing developments and insights shared by professionals on platforms like LinkedIn.