Introduction to China CNC processing

In the field of modern manufacturing, China has become a hub for CNC processing services, providing high-quality precise parts to industries around the world. Among the major players in this field is a professional five-axis CNC processing manufacturer Light. With its advanced equipment and production technology, Great Light specializes in solving metal parts manufacturing problems and provides one-stop post-processing and finishing services. This feature allows most materials to be customized and quickly processed, making lighting the first choice for custom precision machining needs.

Advantages of CNC processing in China

China’s CNC machining offers several advantages that are popular on the global stage. First, the country has a good infrastructure for manufacturing, with numerous suppliers and manufacturers offering competitive prices without compromising quality. This competitive landscape drives innovation and efficiency to ensure customers get the best product at the best price. In addition, the expertise and experience of Chinese manufacturers, such as great lighting during the handling of complex projects and tightening deadlines, makes it a highly reliable partner for businesses seeking precise machining of parts.

Technical capability

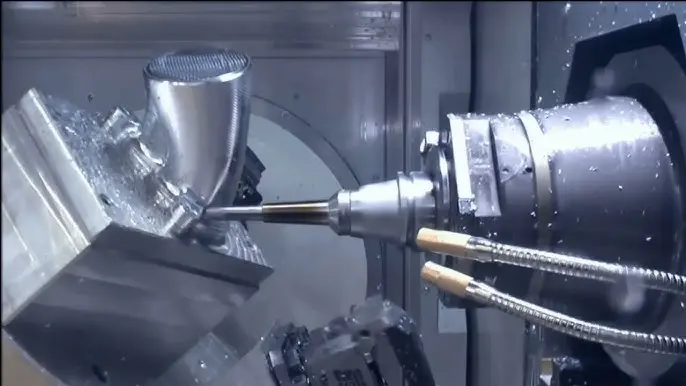

China’s CNC processing services technical capabilities are the most advanced in the world. Manufacturers are constantly updating their equipment to keep up with the latest industry trends and technological advancements. This includes integrated five-axis CNC machining, which allows the creation of highly complex geometric shapes and precise parts to meet the stringent requirements of industries such as aerospace, automotive and medical equipment. The capability of materials ranging from ordinary metals to exotic alloys and plastics further expands the versatility of these services.

Customization and one-stop service

One of the outstanding features of China’s CNC machining, especially in companies like Great Light, is able to provide customization and one-stop service. Customers can design, process and complete their parts according to their specifications. This comprehensive approach simplifies the supply chain, reduces lead times and ensures that all quality and functional requirements are met in a simplified process. Whether it is rapid prototyping, small batch production or large-scale manufacturing, the flexibility and responsiveness of Chinese manufacturers meet a variety of customer needs.

Global accessibility and competitive pricing

The global accessibility of China’s CNC processing services has been greatly improved through advances in communication and logistics. Customers from around the world can easily contact manufacturers, discuss project details and track production progress in real time. Furthermore, there is no quality trade-off in competitive pricing offered by Chinese manufacturers, which makes their services attractive to businesses looking to optimize their supply chain costs. This accessibility and affordability plays a crucial role in establishing China as the main destination for CNC processing.

in conclusion

In short, the Chinese CNC processing industry, led by manufacturers such as Great Light, has established itself as a key component of global manufacturing. With its advanced technology, focus on customization and commitment to providing high-quality precision parts, China continues to attract global industries. Combining technical strength, manufacturing expertise and competitive pricing position, China CNC processing services are an indispensable resource for enterprises seeking innovation and development. Whether you are looking for precise parts for new product launches, prototyping or extended production, China’s CNC machining capabilities can effectively meet your needs.

FAQs (FAQs)

What is CNC machining?

- CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machines to accurately cut and shape materials such as metal, plastic and wood. It is widely used in the production of precision parts and prototypes.

Why choose China CNC processing service?

- Select high-quality products of China CNC processing services, competitive prices, advanced technology and the ability to effectively handle complex manufacturing projects.

What materials can CNC processing process?

- It can handle a variety of materials including metals (aluminum, stainless steel, titanium, etc.), plastics and wood. The choice of material depends on the specific application and requirements of the parts being manufactured.

How long does CNC processing take?

- The time required for CNC machining can vary greatly depending on the complexity of the part, the materials used and the amount required. Simple parts can be produced quickly, while more complex parts or large production runs can take longer.

Which industries use CNC processing?

- CNC processing is used in various industries, including aerospace, automotive, medical equipment, consumer electronic equipment and industrial equipment. Due to the precision and customization it provides, its applications are varied.

- How do I find a reliable CNC processing manufacturer in China?

- Finding reliable manufacturers involves researching potential partners, reviewing their portfolios, requiring recommendations, and ensuring they have the necessary certifications (such as ISO 9001) and experience in similar projects. It is also crucial to communicate directly to discuss project details and features.