Challenge: Significantly accelerate and simplify the process of manufacturing discontinued automotive parts from scratch, without compromising quality and precision.

Solution:Artec Leo、Studio Artec、AutoDesk aliases、SOLIDWORKS

Result: useArtec Leodigitize data for reference, from old physical parts to brand newGUJATThe time it takes for a model to be ready for manufacturing or prototyping is reduced from days to hours.

Why chooseArtec:LionOffers the freedom to build from scratch, unmatched by other options. With less time spent capturing data, more time can be spentGUJATModeling, design and prototyping

1、background

Chad ForwardSince5I knew what I wanted to build from the age of 18. Manufactured in Australia’s leading automotive design studio and custom car workshop15After years of design consulting, he founded his own companyScratch construction companypursuing the career he always loved: making cars.

Scratch constructionHAS2012years likeBeforeWhat started as a side hustle over the weekend became a space for design and collaboration. there,Beforeand its subcontractors (automotive designers, technicians and electricians) work to create solutions for the automotive aftermarket and custom car design.

“I’ve always been attracted to people who are passionate about trying to create things”Beforeexplain. “Looking at the brilliant engineers and designers at Toyota, Ford and other design studios, I really realized that hiring these people and creating a workshop for them all to come and create something would benefit the Australian automotive market.”

Just like the name of his studio,BeforeMuch of what is done has to be built from scratch, whether it’s parts that can no longer be purchased or entire processes that the customer wants to reinvent. until2017Years ago, he spent a lot of time reversing his workflow, with little results. “Sometimes it takes me a whole day to measure the chassis, get real baseline measurements, and then try toGUJATmodel based on this information”,BeforeAdding: “I often miss critical items because I’m pressed for time and have to go back and forth and rework things. »

Scratch constructionof founders useArtec LeoMeasure any room easily(Photo ofstreetmachine.com.au)

»LionasArtecThe most advanced, truly portable scanner ever3DA major revolution in the scanning industry. “

SOArtecWireless handheld3DScannerArtec Leohour,BeforeI was immediately won over. He said: “20Years ago when I was in the custom car business, I didn’t think this technology would exist in my lifetime. »BeforepassArtecAustralian distributorObjective3DThe scanner was ordered and, as the team recalls, he was the first lucky customer to receive one.

“LionasArtecThe most advanced, truly portable scanner ever3DA major revolution in the scanning industry. WeObjective3DWe are proud to introduce this technology to the Australian and New Zealand markets,”Objective3Dgeneral managerMatt Miniosaid: “This is particularly useful to automotive engineers who can useLionReverse engineer the parts and find out how they affect your car’s performance. “

Artec LeoDesigned with both mobility and ease of use in mind, it is a powerful and unique tool.3Dscan, no needPCor a laptop to use. The scanner is equipped with a wide-angle lens that can easily capture medium and large industrial parts and perform vehicle inspections.3DScans with guaranteed accuracy and excellent resolution.

Equipped with on-board automatic processing, wireless connectivity, an integrated touch screen and a battery, the scanner offers complete autonomy and freedom of movement, no matter where the user is: in a Custom car manufacturing shop, factory or remote location without electricity.

RIGHTBeforeIt’s obvious: “It took me four years to make the decision to spend4,000dollars to buy one3Dprinter but convinced me to buy it4The scanner, which cost more than $10,000, was only used to15minute. “

2、start working

Once the scanner is delivered,BeforeI just put it straight to work and haven’t stopped since. Today, everything that needs to be measured on a car is measured byLionPerforming analyses, whether in store or in the field, saves him and his customers valuable time. Now he spends the rest of his time working on auto parts.GUJATModeling, design and prototyping, using digitized data as reference.

“I can’t believe how much freedom a device gives me. I am now able to easily capture data, regardless of location or complexity of the part.Beforeadded.

BeforeExploitLiondata asSOLIDWORKSAndAutodesk aliasesmediumGUJATModeling reference

(Photo ofstreetmachine.com.au)

Usually the workflow looks like this:BeforeOr one of their designer colleagues goes to the client to scan a specified object, then all the data is transferred to one of their dedicated colleagues.Studio ArtecProcessed on a desktop computer.

“I have two desktop computers: one to process all the scanned data and one toGUJATModeling. As I always have projects in progress, I prefer to be able to work on them simultaneously,”Beforeexplain. Then, depending on the part scanned, load it intoSOLIDWORKSOrAutodesk aliasesused to create entities inGUJATModel.

Artec LeoThe integrated touch screen allowsBeforeAbility to preview analysis results in real time

(Photo ofstreetmachine.com.au)

Use where your customers are3DThe scanner is alsoBeforebrought new job opportunities: “Every time I bringLionGo somewhere on a business trip and you are sure to receive another new project from the area. The client would refer me to another place, that sort of thing,” he explains. In the field, he also collected more data than necessary, creating his own parts catalog from data he couldn’t find.

3、1957van year

So far,BeforeThe biggest project ever done with a scanner –1957YearInternational Metro Step VanRestoring the van he and his business partner from another auto garageLuke Williamsprovided for in2023Complete the recovery from scratch by the end of the year.

The owner of this van not only wanted to restore the vehicle to its original condition, but also wanted to combine its retro look with the power of a sports car, equipped with a supercharger.6.2ElevatorHEMI Hellcat V8engine.

The most powerful American muscle car of the momentDodge Challenger SRT® HellcatStandard model configuration,V8Have more than700power, unlike the original car engine, which will allow the owner to freely drive his van across the country. In addition to the engine, he also wanted to modify the design to make the van less “bloated” and retain all the original electronics.

Before restoration1957YearSubway vanOriginal bodywork (Image source:Chad Forward)

After gathering the owner’s design and engineering requirements and making some preliminary sketches,BeforeAndWilliamsA plan was proposed: since the original body was too old and rusted beyond repair, it would be quicker to build the entire car from scratch, using scans of old and rebuilt parts asGUJATThe basis for modeling new parts.

3、1 First phase: sculpting the body

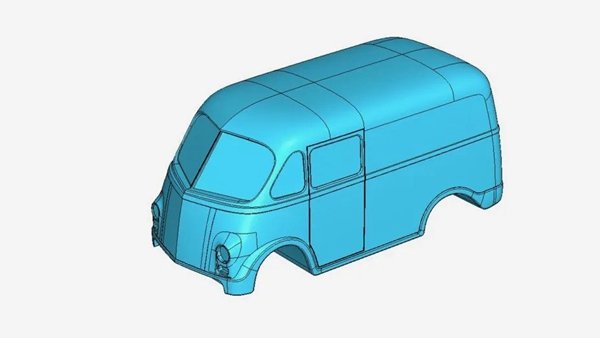

First step: Cut and engrave the body. The plan is to reshape the existing body or any of its components into the desired shape and then make the3DScan and store full body data in theGUJATstarting point of the modeling.

To do this,WilliamsThe original bodywork was cut out with an angle grinder, rewelded in slightly different places, then lots of body filler and primer was used to create a matte finish he was happy with.

Plan to modify one of the body parts into the desired shape and then3Dscanning+The whole bodyGUJATModeling

(Photo ofstreetmachine.com.au)

3、2 Phase two: chassis construction

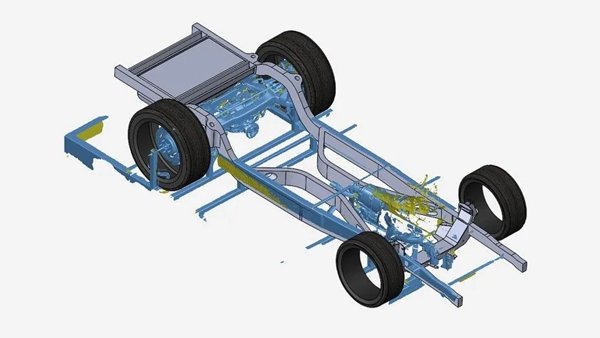

at the same time,BeforeWillDodge HellcatAll of the drivetrain components – the engine, all the wiring, the front and rear suspension – are mounted on a basic platform that he built around the chassis. He wanted to see how all the components fit together and if they fit togetherADR(Australian Design Rules) and analyze them to identify new chassis components that need to beGUJATaverage modeling.

3、3 The third step:3Dscanning

FollowingBeforeuse yourArtec LeoScan the left front corner of the vehicle as well as the chassis and other interior components. All scans only take a few minutes; it then downloads all the data toStudio Artecprocess and create.STLdocument.

to useArtec LeoScan the van(Photo ofstreetmachine.com.au)

to useArtec Lion 3DScan the modified body

rear suspension3Dscanning

3、4 Step 4: Shape the body

Next: modeling of the body surface. for this purpose,Beforewill come fromStudio ArtecImporting scanned dataAutodesk aliaseswhich is used for automobile exterior decorationGUJATIndustrial design software and use this data as a template to sketch the future body surface.

Beforeto useAutodesk aliasesThe software creates body surfaces based on sketches it has made using scanned data.

(Photo ofstreetmachine.com.au)

Aliasin the software3DScan (light blue) andGUJAT Data (blue)

3、5 Step Five: Chassis Modeling

Beforeto useSOLIDWORKSfor modeling the chassis and all other engineering components. Following the same workflow, he would useLionThe captured analysis data is uploaded toSoftwareand model new parts around this data. Get Accurate Internal Components3Dcopy,BeforeHe can use them as a precise reference during the design process and also better understand the problems he will encounter. As the design progressed, he scanned more parts and added them to the software as reference models.

BeforeScan the chassis used for modeling asSOLIDWORKSCreated inGUJATThe basis of the model

3、6 Phase six: Laser cutting and welding of new components

passing throughSOLIDWORKSAfter treatment,Beforedoes everythingGUJATThe components are transferred to a laser cutter and then welded to the chassis.

Laser cutting of flat parts to be assembled before welding to the chassis(Photo ofstreetmachine.com.au)

Once all chassis components are welded, the complete internal structure is sent to an automotive electrician who attaches the chassis toHellcatof original parts assembled together. at the same time,BeforePreparation of the body surface to be cut based on digital data modeling (pp.4step), to stamp car bodies, which are then used to make panels and test components.

BeforeFinal design of the new body exterior that will be used to create body stampings

The team anticipates that in the future12Complete all bodywork within a few months and allow a few more months to complete the2023Interior work, painting and other finishing work will be completed by the end of the year. Once finished,BeforeHopefully this project will serve as a bridge to inspire other studios and clients.

“I thinkSubway vanA great example of how to reinvent the entire car. »Beforeexplain. “Even though our process is lengthy, restoring an old car to its original condition is much better than restoring it to new condition.3DBuilding from scratch, supported by scanner data, takes longer. capable of capturing3DData, reverse engineering, parts manufacturing: that’s how I started my business. “

“WhenHDWhen the model came out, I was blown away, as if I had bought a brand new scanner. “

BeforeI never hesitated to switch to3Dscanning. Being able to create precise digital copies of automotive parts, eliminating the need for manual measurements, has completely changed the way they work, improving the accuracy of their data collection and overall productivity.

And all this will improve day by day.“I have always been rightArtecI am impressed by the continuous improvement and upgrade to stay ahead of the curve,” he said. “Every software upgrade is a new experience for me.Artec Studio15And16The difference betweenHDWhen the model came out, I was blown away, as if I had bought a brand new scanner. “

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.