Metal 3D printing is experiencing rapid development – the most typical representative isGEAviation has achieved more than10Manufacturing of 10,000 nozzle heads and application in the most advanced engines:

Boeing777XdoorGE9X

airbusA320 NEOdoorJUMP-1A

Boeing737MAXdoorJUMP-1B

ChinaC919doorJUMP-1C

So, can batch 3D printed metal parts be widely used in aerospace?

2022at the Zhuhai Air ShowLEAPengine

it will originally come from20Components manufactured by welding are combined into a precise whole, making the product lighter than the previous generation.25%improved durability5times, profitability increased30%its complex feature structure requires that it can only adopt3DManufacturing of the printing process. The success of this business shows that the metal3DPrinting is feasible for mass manufacturing.

National information on aerospace metals3DAlthough the cases of mass printing and manufacturing have not been published, clues can still be found. There is such a statement in the latest application file of the Sixth Aerospace Academy.85During the development and manufacturing process of multi-ton open-cycle liquid oxygen engines, “3DKey printed components have undergone dozens of reliability evaluations in long-term testing. “This proves from the side that the metal3DThe quality of parts produced by printing technology is reliable and can be accepted by the aerospace field. Following,3DThe Printing Technology Reference Paper will describe, from a production perspective, what factors influence mass production for the aerospace sector.

1. Product consistency, a key factor for reproducible manufacturing

Carrying out mass manufacturing represents the metal3DEvery part printed in a single batch or multiple batches is completely consistent, from part quality to dimensional accuracy to performance, meaning the technology delivers repeatable build quality . This imposes strict requirements on printing equipment and process standards for well-known metals.3DPrint markBike3DClaims that any of its machines deployed around the world can print parts of the same quality, which is an improvement over metal3DPrint a good example of product consistency in batch manufacturing.

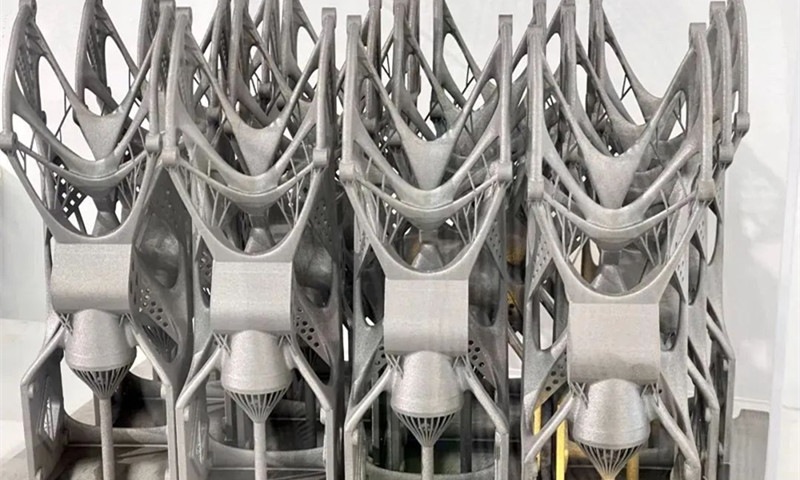

Mass-produced mounting bracket showcased by BLT at Zhuhai Airshow

Equipment must be adapted to strict standards and be able to achieve reproducible manufacturing quality, in order to have the basic conditions for mass manufacturing. But this is just a systematic description, but it covers a wide range of things, such as eliminating smoke and controlling airflow in the forming space during the printing process, the stability control of laser power and energy control at each point. of the platform within an acceptable range, printing The number of sensors required to monitor the oxygen content in the chamber and the post-processing required once construction is complete can reach thousands.GEacquiredConceptLaserThe printer has also been meticulously researched, analyzed and adapted to meet its mass manufacturing capabilities.

2. Well-trained engineers are essential

for metal3DPrinting technology certainly requires a lot of professional knowledge, but it does not require a single person to be versatile. This technology involves many technical details, such as design for additive manufacturing, qualified operation and maintenance, printing process development and material quality control, post-processing, etc.

Almost all of these processes involved will directly affect the consistency of the manufacturing quality of the product. For suppliers dedicated to providing services to the aerospace industry, the talent engaged in these connections is indispensable, especially those who are well-trained engineers. Training engineers with these specialized skills is expensive and time-consuming, but essential.

3. Manufacturing costs must continue to fall

It is important to note that unless the return on investment exceeds other available production methods,3DPrinting technology will not be widely adopted for mass production. For the aerospace industry, cost may not seem to be the most important thing, but it continues to determine whether volume production can be achieved.

Xin Jinghe Metal3DPrinting workshop

A major problem is the high cost of the machine itself. However, after ten years of technology accumulation and R&D iterations,3DThe cost of printer equipment has decreased significantly compared to the early days. Likewise, there is a consistent trend in material costs.

At present, there are already a number of additive manufacturing service centers in China that deal with manufacturing in the aerospace field, such as Platinum, Xinjinghe, Falcon and Gangyan Jiguang. Depending on the deployment, at2025Domestic metal oriented3DIt is estimated that the number of printing service equipment far exceeds600Desktop (click).

Whether from a technology maturity or competition perspective, continued reductions in manufacturing costs will be inevitable.

4. Automated regulation and production will become increasingly

Minimizing human error is crucial for metal additive manufacturing. For example, when adjusting the spot size and parameters for multi-laser splicing, engineers may have different judgments. Therefore, some equipment manufacturers such as Farsoon High-tech have developed independently.The “multi-laser intelligent calibration system” maximally solves the challenge of multi-laser overlap consistency, making the printing quality and performance more uniform.

Other human-made errors include leveling build substrates, powder cleaning parts’ internal pipes, and removing and post-processing supports. Today’s software and hardware make these processes smarter. Although the current degree of automation is still limited, it appears to be a trend.

The application advantages of metal additive manufacturing technology in aerospace field include liberated design, high material utilization, low manufacturing cost, rapid manufacturing, etc. After experiencing initial doubts, it began to grow rapidly. This article mainly describes the impact of metals from the production process perspective.3DFactors related to mass production printing.

as3DAs one of the contributors to Print Technology Reference pointed out, the metal3DPrinting is not just about “being able to print”, performance must meet installation requirements, mass production must be stable, efficient and consistent, costs must continue to be reduced, and the ability to Design innovation and process improvement and upgrades must also continue to improve. Only in this way can it become an indispensable link in the manufacturing supply chain, and only then can this once “non-routine” process survive in the cold of winter.

Source: Reference on 3D printing technology

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.