existIn 3D modeling, a vertex is a single point in three-dimensional space. A single vertex has three coordinates: the values of the X, Y and Z axes.

Adding vertices improvesThe detail and control of 3D models is crucial. For example, if you’re optimizing an existing project, placing vertices on edges or faces can result in more precise sculpting, especially in complex areas. After adding vertices, you can use them to seamlessly connect objects or edges, resulting in clean geometry, which is crucial for high-quality modeling or to avoid issues when modeling. 3D printing.

However, you should be careful when adding vertices, as overly detailed geometry can overcomplicate the object and even lead to non-multiple edges and floating vertices. If you are modeling for animation, you may want four vertices per face, as this makes it easier to deform during movement.

existThere are several techniques for adding vertices in Blender, each serving a unique purpose. Next, we’ll look at some options related to adding vertices.

A,Ctrl+right click

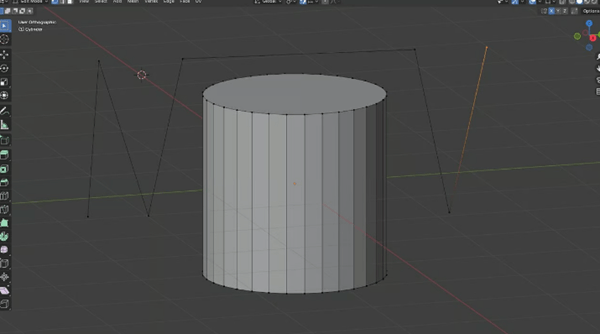

Create and link vertices by edges on the cylinder (Source:Ofonime William via All3DP)

also known asThe “right click add” method is the easiest and fastest way to add vertices in Blender. Here’s how to do it:

1. Import (or create) your model first.

2、according toThe “Tab” key allows you to switch from “Object” mode to “Edit” mode.

3、Press and hold“Ctrl” key and right-click in the direction you want to place the vertex.

If an edge or vertex is highlighted (selected), then when you press and holdThe “Ctrl” key and right click will create a new vertex connected to this vertex by an edge.

two,Segmentation

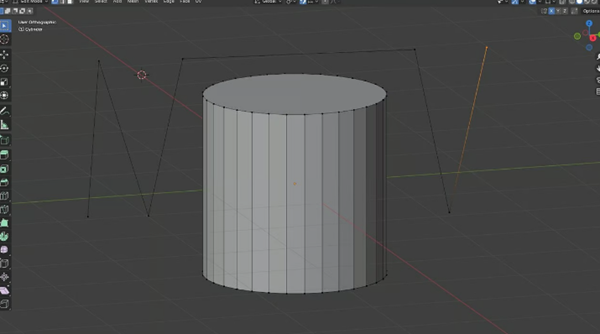

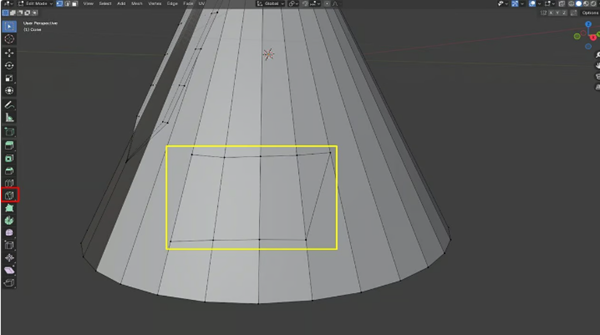

Cone with subdivided edges resulting in multiple vertices (source:Ofonime William via All3DP)

also known asThe “Add Vertices to Edges” method, which allows you to add more details to a part. It allows you to manipulate geometry into more precise shapes.

Here’s how to add vertices by subdividing edges:

1、Again, place the object in the workspace and pressThe “Tab” key (red) switches to “Edit” mode.

2、move on to“Edge Selection” (yellow, second option) and select the edges you want to subdivide.

3、right clickanywhere in the 3D view to open the vertex context menu.

4、choose“Segmentation”.

5、existIn the lower left corner of the 3D view, a control panel (green) will appear. Here you can change the number of vertices added; this will split the edges based on the number of vertices, adjusting smoothness and other variables. This method also works with faces (another type of object).

Note that this creates vertices at the ends (ends) of the subdivision edges, you will need to return to“Vertex Selection” mode (yellow) to find newly added vertices.

three,Merge edges with vertices

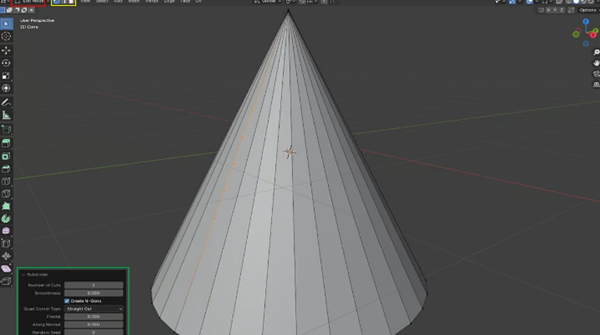

Vertex Slide applied to the top edge of the box (Source: Ofonime William via All3DP)

Discontinuous geometry within a single object can lead to complex problems, including non-multiple geometry,n-gons and strange artifacts. You can connect meshes using Boolean operations, but this can sometimes lead to unexpected results. Edge blending is more precise by adding and merging vertices at specific locations, like this:

1. Use the subdivision method we learned in the previous section to add vertices near the contact points.

2、to useThe Vertex Slide (Shift+V) function positions the new vertex as close to the contact point as possible. It will slide in the direction of mouse movement and can be held in place with a left click.

3、Select a vertex and holdShift and select another vertex. Press the “M” key to use the merge function, then select how you want to merge the vertices from the available options.

Please note that“n-gons” is short for polygons with more than four sides, such as a hexagon (six sides) or any other shape with “n” sides. They are useful for modeling complex shapes, but can cause problems with animation and 3D rendering, especially when subdividing or deforming the model. The higher the number of edges, the more unpredictable the results, which can be particularly problematic if you plan to 3D print the model.

Four,Add-on “Additional objects”

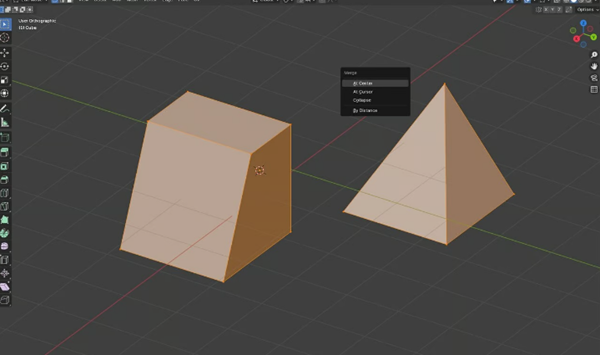

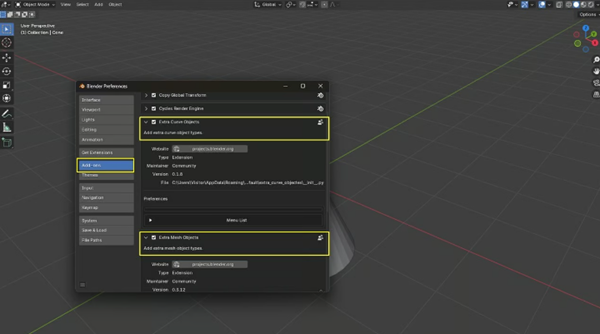

Install the plugin locally (source:Ofonime William via All3DP)

You can useThe “Extra Object” method adds a single vertex as a new object. If you are using a version of Blender earlier than 4.1, you will need to install the Extra Mesh Objects and Extra Curve Objects add-ons. There are several ways to do this; Let’s look at one of the simplest:

1、To install the plugin locally, you need the installation files. You can modify it directly fromBlender extensions are downloaded to the local device (desktop).

2、Go toGo to Blender’s Edit menu and select Preferences.

3、scroll to“Add-ons” you can search for all available add-ons to customize your version of Blender. In the upper right corner, select “Install…” to install the add-on you just downloaded.

4. Navigate in the window to find and select the add-on.

5、After installation, make sureThe Additional Mesh Objects and Additional Curve Objects boxes are checked. Close the menu.

Or if yourStarting with Blender version 4.1, these steps are no longer required because the add-on is now part of the setup. However, you need to enable them by going to Edit > Preferences > Add-ons and checking “Add Curves: Additional Objects” and “Add Mesh: Additional Objects”.

now, inIn Object mode, you can select Add (or Shift+A) and navigate to Mesh > Single Vertex > Add Single Vertex. By default, this adds a vertex to the origin, but you can change the target position using the submenu options.

five,Alternative method

Vertices generated using the cut tool based on the cut path (yellow) (Source:Ofonime William via All3DP)

These are secondary (less commonly used) methods that create vertices immediately or by making them easier to create and manipulate. Let’s see what they are.

1、Knife tools: inIn “Edit” mode, this will add vertices in a controlled manner, depending on the path traveled by the tool (yellow). Note that this will introduce some edges. The image above shows the vertices added next to the edge, representing the part where the cutting tool (red) is placed.

2、Poke Faces: This feature works best with faces, allowing the addition of vertices and certain edges that can be exploded or removed. existIn Edit mode, switch to Face Selection and click the face you want to add vertices to, right-click the face and select Face Stamp from the options. As mentioned before, this will be a peak in the center of the face.

3、Extrude: inIn “Edit” mode, select “Vertex Selection”, select the desired vertex and press command “E” to extrude it (a new vertex will be created). If you select two vertices that form an edge, command “E” will extrude a face.

4、Auto-merge vertices: This method collapses vertices to a single vertex. existIn Edit mode, from the Properties menu on the right side of the workspace, select Tool Settings (starting at the top). Expand Options, enable Auto Merge, and change the Threshold to 0. Then select the vertices you want to merge, click the “S” and move your mouse in the direction you want the merged vertices to appear, then click on them with the left button.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.