Commonly used raw materials for sheet metal processing include cold-rolled steel plates (SPCC), hot-rolled steel sheet (SHCC), hot-dip galvanized sheet (SECC、SGCC),copper(CPU) Copper, red copper, beryllium copper, aluminum alloy plate (6061、5052、1010、1060、6063carbon tool steel, etc.), aluminum alloy profiles, stainless steel (mirror glass, brushed metal surface, fog), depending on the function of the product, the raw materials used are different, which generally need to be considered in the purpose and cost of the product.

1. cold rolled steel plateSPCCmainly using electroplating process and baking painting process parts, low cost, easy to form, raw material thickness ≤3.2mm。

2. hot rolled steel plateSHCC,raw materialsT≥3.0mm,Also uses electroplating process,Painted parts are inexpensive, but difficult to form, and tablet parts are mainly used.

3. hot-dip galvanized sheetSECC、SGCC。SECCElectrolytic plate pointsNcosts,P.costs,NThe key to the material is that there is no surface treatment and the cost is relatively high.P.Material used to paint the parts.

4. Copper ; it mainly uses materials with conductive function, and its surface treatment is nickel plating, stainless steel or untreated, and the cost is relatively high.

5. An aluminum alloy plate is generally used for a surface layer of chromium trioxide (chromium trioxide).J11-A), oxidation (conductive oxidation, chemical oxidation), the cost is relatively high, there are gold plating and nickel plating.

6. Aluminum alloy profiles; Materials with complex cross-sectional structures are widely used in various plug-in boxes. The surface treatment is the same as that of aluminum alloy plates.

7. Mainly used stainless steel without any surface treatment, the cost is relatively high.

Cutting method for sheet metal processing:

There are different methods of cutting materials, the main methods are:

① Shears: Shears are used to cut single pieces of strips. It is mainly used to prepare and process cutting molding. It is inexpensive and less precise than this one.0.2but only the surface layer of strips or blocks without holes or right angles can be processed.

② Stamping machine: The stamping machine is used to cold stamp the parts of the computer tablet after the parts have been processed on the furniture panels in one or more steps to form various material shapes. It features short construction time, high efficiency and high precision. , and low cost, suitable for mass production, but the mold needs to be designed.

③North CarolinaCNC machine tool cutting,North CarolinaWhen cutting, the first step is to write a CNC machine tool processing program and use CNC programming software to compile the developed drawing into aNorth CarolinaThe program that the CNC lathe can identify allows it to cold stamp parts of different shapes onto the tablet, one step at a time. However, its structure is determined by the structure of the CNC blade, and low cost and precision are not enough. .0.15。

④Laser cutting is to use fiber laser cutting method to cut out the structural shape of the tablet on the large tablet, and at the same timeNorth CarolinaCutting materials also requires writing a laser program, capable of downloading tablet components of various complex shapes. The cost is relatively high and the accuracy is lower.0.1。

⑤ CNC sawing machine: It mainly uses aluminum alloy profiles, steel square tubes, drawing tubes, round rods, etc., which are inexpensive and low precision.

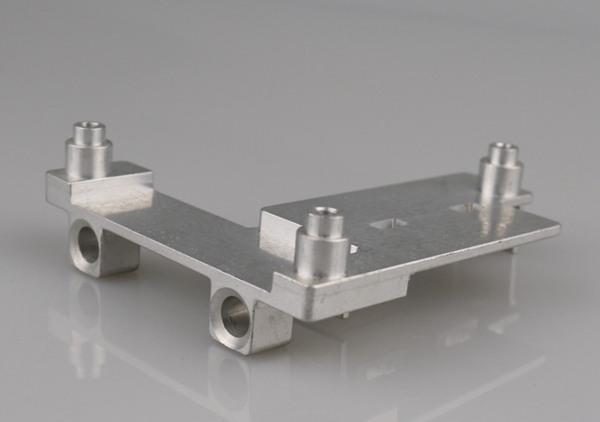

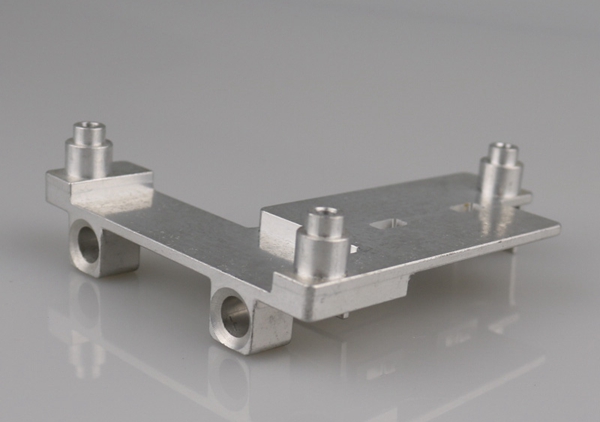

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.