Turning internal holes is also called reaming. It uses turning to enlarge the inner hole of the workpiece or process the inner surface of the hollow workpiece. It can be processed by most cylindrical turning techniques. Today we will discuss common problems in internal hole turning and provide practical solutions to teach you how to solve them easily and make internal hole processing more comfortable.

1

Internal Hole Turning Problems

1) Furito

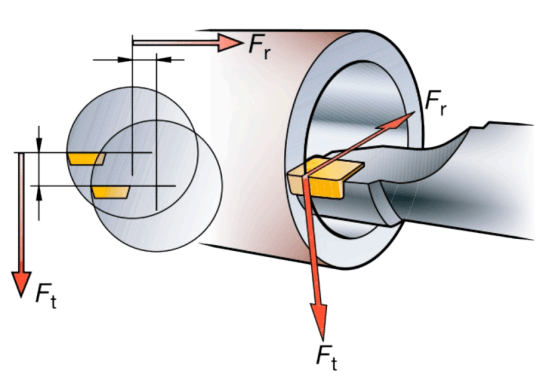

Long overhangs are a major cause of blade deflection and vibration problems. The inner hole turning tool is subjected to both radial force and axial force, which will cause the tool tip to deviate from the predetermined position, causing deformation of the tool holder. The longer the tool holder, the more obvious the deformation will be. will be, and the more obvious the vibration will be.

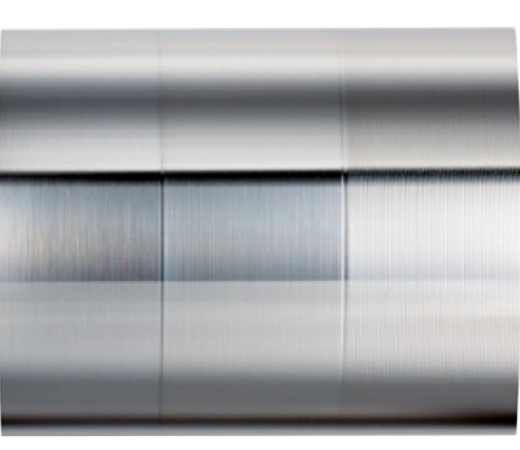

2) Poor surface quality

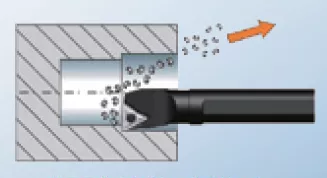

Poor chip removal can result in poor surface quality of the part. If the iron shavings cannot be removed from the inner hole as expected, they will press and rub the inner wall of the workpiece, causing the inner hole turning process to fail.

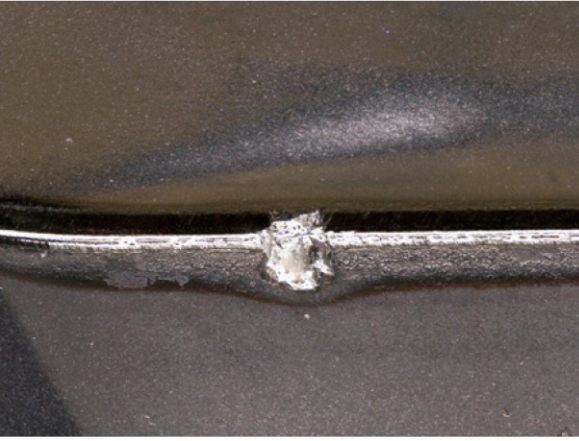

3) The blade breaks easily

Vibrations and poor chip evacuation can cause the blade to break. The blade is prone to chipping during vibration and extrusion of iron shavings.

2

Solutions to Internal Hole Turning Problems

1) Basic principles

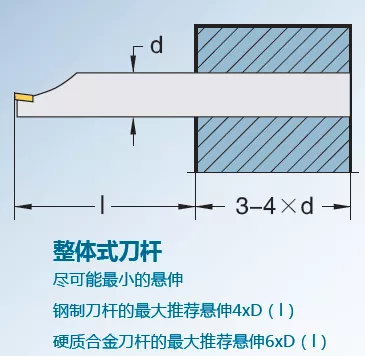

The general rule for machining internal holes is to minimize tool overhang and choose the largest tool size possible for maximum machining accuracy and stability.

2) Factors that improve the quality of inner hole processing from the perspective of tool application

Selection of insert geometry:

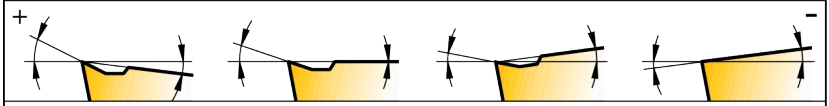

The geometry of the insert has a decisive influence on the cutting process. For machining internal holes, a positive rake angle insert with a sharp cutting edge and high edge strength is generally used.

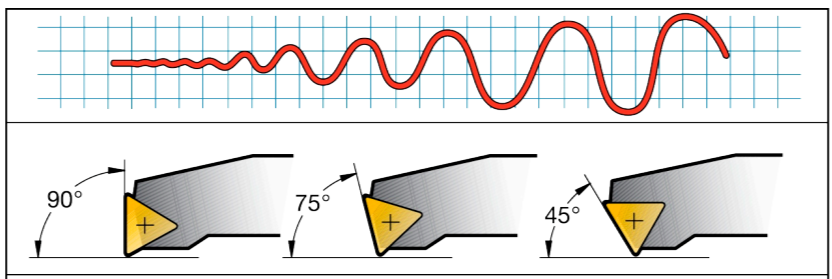

Selection of the main declination angle of the tool:

When selecting the main declination angle, it is recommended to choose a main declination angle as close as possible to 90° and at least 75°, otherwise the radial cutting force will increase sharply.

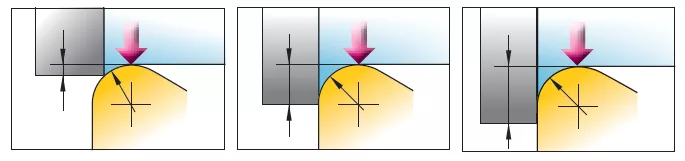

Tool nose radius selection:

In internal hole turning operations, small tool nose radii should be preferred. Increasing the tool nose radius will increase radial and tangential cutting forces, and will also increase the risk of vibration tendencies. At the same time, using the maximum nose radius achieves a stronger cutting edge, better surface texture and more uniform pressure distribution on the cutting edge while ensuring minimal radial cutting.

3) Efficient chip discharge

When turning internal holes, chip removal is also very important to the processing effect and safety performance, especially when processing deep holes and blind holes.

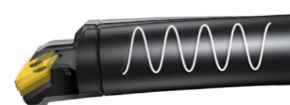

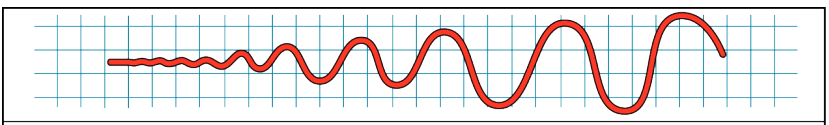

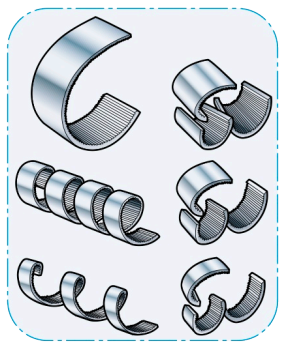

Shorter spiral chips are ideal chips for internal hole turning. This type of shavings is easier to evacuate and will not put much pressure on the cutting edge when the shavings break.

If the chips are too short during processing and the chip breaking effect is too strong, higher machine tool power will be consumed and there will be a tendency to increase vibration.

If the chips are too long, it will be more difficult to remove them. The centrifugal force will push the chips toward the hole wall, and the remaining chips will be pressed onto the surface of the workpiece, resulting in the risk of falling. chip clogging and tool damage.

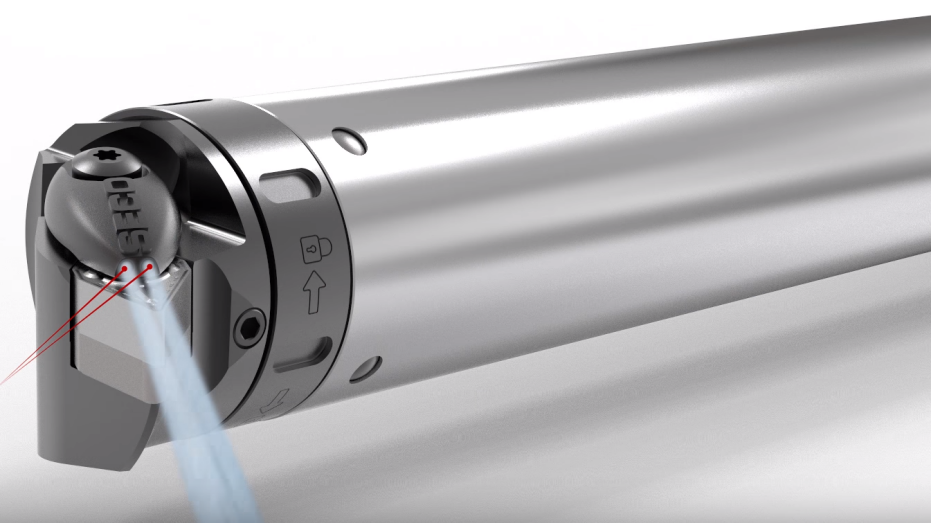

Therefore, when turning internal holes, it is recommended to use tools with internal coolant. This way, the cutting fluid will effectively force the chips out of the hole.

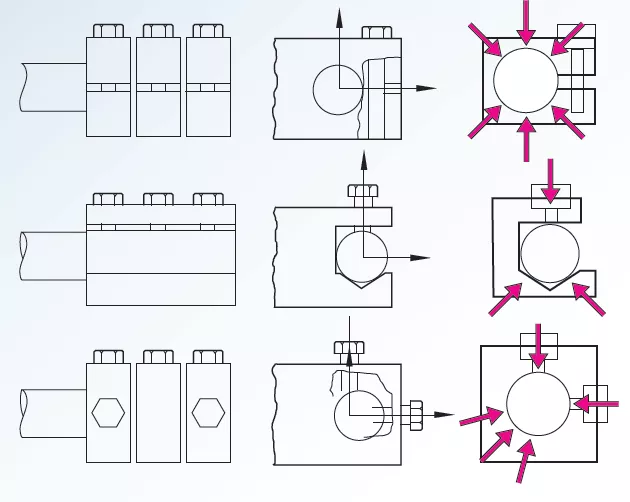

4) Selection of tool tightening method

Tool clamping stability and workpiece stability are also very important in internal hole machining. They determine the magnitude of vibrations during machining and whether these vibrations will increase. It is very important that the tool holder clamping unit meets the recommended length, roughness and hardness.

The overall support is better than the toolbar directly clamped by screws. It is more suitable to tighten the toolbar on the V-shaped block with screws. However, it is not recommended to use screws to directly tighten the cylindrical handle toolbar because. the screw will be damaged if it acts directly on the toolbar.

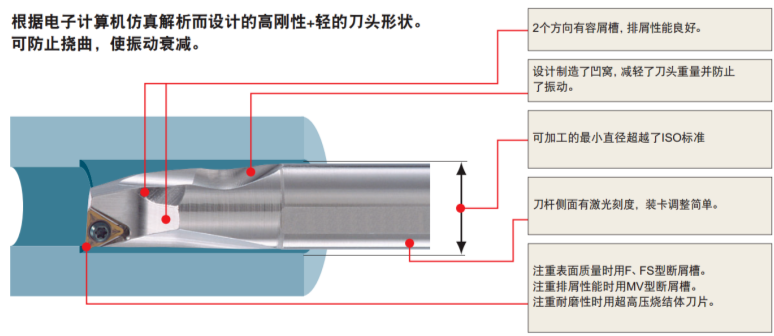

5) Use a special toolbar to reduce vibration and increase effective iron shaving removal.

Damping shaft

This type of tool holder generally uses solid carbide as the tool body, which can effectively reduce tool vibration in the area of small holes.

Damping Tool Holder Features:

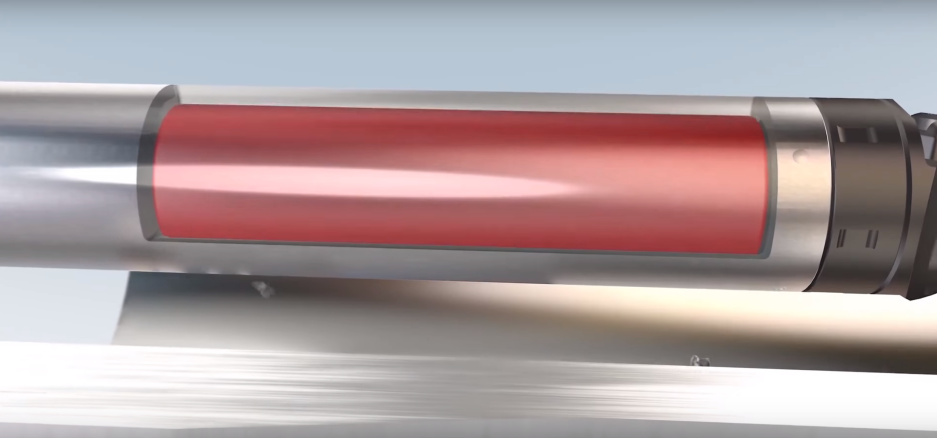

Anti-vibration tool holder

This type of tool holder usually has an anti-seismic unit inside the tool holder, which can effectively reduce vibration caused by excessive overhang.

However, this type of anti-seismic means based on cutting tools is often expensive and presents difficult application scenarios.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.