In recent years, high-performance thermoplastics have3DPrinting applications are becoming increasingly important as technology gradually moves from rapid prototyping to the production of finished parts. Therefore, for3DThe requirements for printing materials are increasingly higher and high-performance thermoplastics are increasingly used in applications. Their properties make them a profitable alternative to certain metals, sought after in many sectors including aerospace and medical. In this series we find the polyaryl ether ketone (PAEK), it can withstand high temperatures, you might be interestedAT A GLANCEAndlardrelatively familiar. Polyetherimide (PEI) is a cheaper alternative, an amorphous material sold under the trade nameULTEM®. like a kind ofFDMMachine compatible filament, which is compatible with certain machines, includingStratasysCompany machines. Let’s seeULTIMATEmain characteristics.

PEIHAS20century80Date byJoseph G. WirthDeveloped and manufactured by GE Plastics asULTIMATEsales on behalf of2007In , the company sold its plastics business to Saudi Basic Industries Corporation (SABIC)SABIC), which took over the patents concerned. althoughULTEM®The mechanical properties ofFDM/FFFIt was only after the advent of printers that they became suitable for mass production. The extruders in these printers must be able to reach high temperatures to melt the thermoplastic.

ULTEM/PEIproduction and characteristics

ULTEM®is made of polyetherimide (PEI) series of amorphous thermoplastic materials. One of its main characteristics is its flame retardant properties: high flame retardancy, low smoke production and low toxicity. These characteristics are inTVF(Flame, Smoke, Toxicity) were well represented.ULTEM®High temperature resistance, relative thermal index (RTI) accessible180°C。ULTEM®It also has the characteristics of high strength, rigidity, dimensional stability, good creep resistance and high chemical resistance. different kindsULTIMATEIt also has a high strength-to-weight ratio and can even replace some metals due to its mechanical properties and high degree of processability. These materials are available in clear and opaque colors.

ULTIMATEThe material maintains its strength and resists stress corrosion cracking when exposed to automotive and aerospace fluids, aliphatic hydrocarbons, alcohols, acids and weak aqueous solutions.ULTEM® 1010Has high tensile strength and durability. It is biocompatible and passedNSF 51Food contact certification. It can also withstand steam sterilization.

Also,ULTIMATECopolymers can also withstand higher temperatures and adapt to different needs in terms of chemical properties and elasticity.SABICalso introduced throughISCC+Certified renewable range. These are made from waste and residueULTIMATEThe variety has the same characteristics as those made from fossil fuelsULTIMATESame performance and ease of processing. arrive2023Mid-year, renewableULTIMATEThe materials will representSABICprovidedULTIMATEMore than a quarter of the material.

SABICCurrently available140kindULTEM®. It is particularly worth mentioning thatULTIMATE™ 9085CGit is used not only in cabin interiors in the aerospace sector, but also in the railway sector.ULTEM HU1010Used in the fields of medical devices and pharmaceuticals. It is biocompatible.

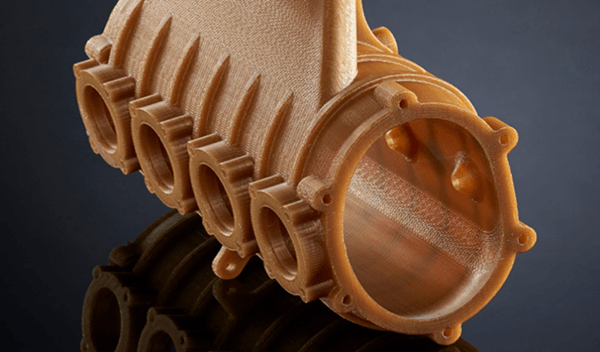

ULTEM/PEIexist3DPrinting applications

impressionULTEM®temperature management is crucial. The temperature of the cavity must be maintained at all times, otherwise irregularities could occur and affect the adhesion between the different layers. Hard amorphous polymers/Transition from glassy to soft state/Rubbery glass transition temperatureULTIMATEIt’s very high,ULTEM1010reach217°C(ULTEM9085reach185°C). For best results, the print chamber temperature should be slightly below the glass transition temperature. This will ensure that the part has the correct dimensions and maintains its mechanical properties. If the temperature is too low, the parts may deform or even crack. Once printing is complete, the print chamber should be cooled slowly and evenly so that the parts cool down gradually.

ULTEM/PEIApplication

As you know,PEIWidely used in aerospace fields, especiallyULTEM®9085because it has the above characteristics. It is also the material of choice in the automotive, medical and food industries, particularly in the design of kitchen appliances. This thermoplastic is also widely used in the design of molds, templates or fixtures. For example, Bombardier (Bomber) uses the material to create custom tools, custom parts on production lines, and finished parts for trains.

source:3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.